3-2 Problems, Causes and Solutions Rev AD

MSSC QM1610 Technical Manual

A dot or dots

missing. Unit ran out of ink. Replace the ink bottle.

Nozzle clogged 1. Spray the nozzle block with solvent.

2. Backflush the nozzle. (refer to

“Backflushing a Nozzle” on page 5-2.)

3. Replace nozzle block. (refer to

“Replacing the Nozzle Block” on

page 5-4.)

Tube and jewel assembly in

the nozzle block cracked. Replace the nozzle block. (refer to

“Replacing the Nozzle Block” on page 5-4.)

Worn valve. Increase dot size to temporarily adjust for

worn valve.

Valve became loose from the

Printhead PCBA. Reseat the valve on the Printhead PCBA.

Valve is defective. Replace the valve. (refer to “Replacing a

Valve” on page 5-6.)

Ink line became loose. Reattach the ink line.

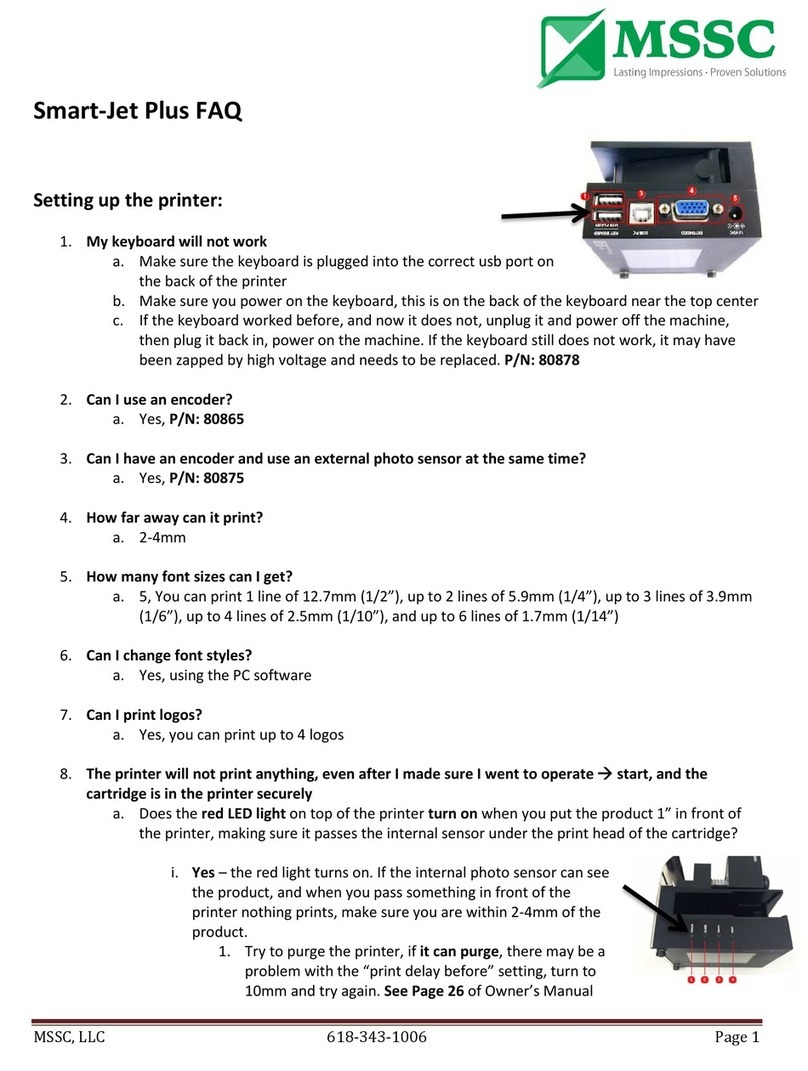

Cable connection loose. Reseat the cable connector.

Oneormorevalves

fail to work,

resulting in missing

dots.

Cable from the controller to

the printhead touched the

PCBA causing a short.

Secure the cable from the controller to the

printhead with a fixed mounting.

Valve is defective. Replace the valve. (refer to “Replacing a

Valve” on page 5-6.)

Printhead PCBA is defective. Replace the Printhead PCBA. (refer to

“Replacing the Printhead PCBA” on

page 5-8.)

The dots are

splattering on the

print sample.

Printhead too far away from

the product. Position the printhead as close as possible

to the product without rubbing against it and

no further than 0.24" (6 mm) away.

Note: Avoid contact between the printhead

and the product as this may cause print

quality to suffer.

Air in system. Purge unit until air is removed.

No power. Unit is not properly plugged

in. Plug unit into an appropriate power source.

Ink is leaking from

the regulator. Regulator is cracked or

defective. Replace the regulator. (refer to “Replacing

the Regulator” on page 5-7.)

Problem Possible Cause Solution

Table 3-1: Problems, Causes and Solutions (Continued)