Rev AE 1

Table of Contents

Chapter 1 — Introduction

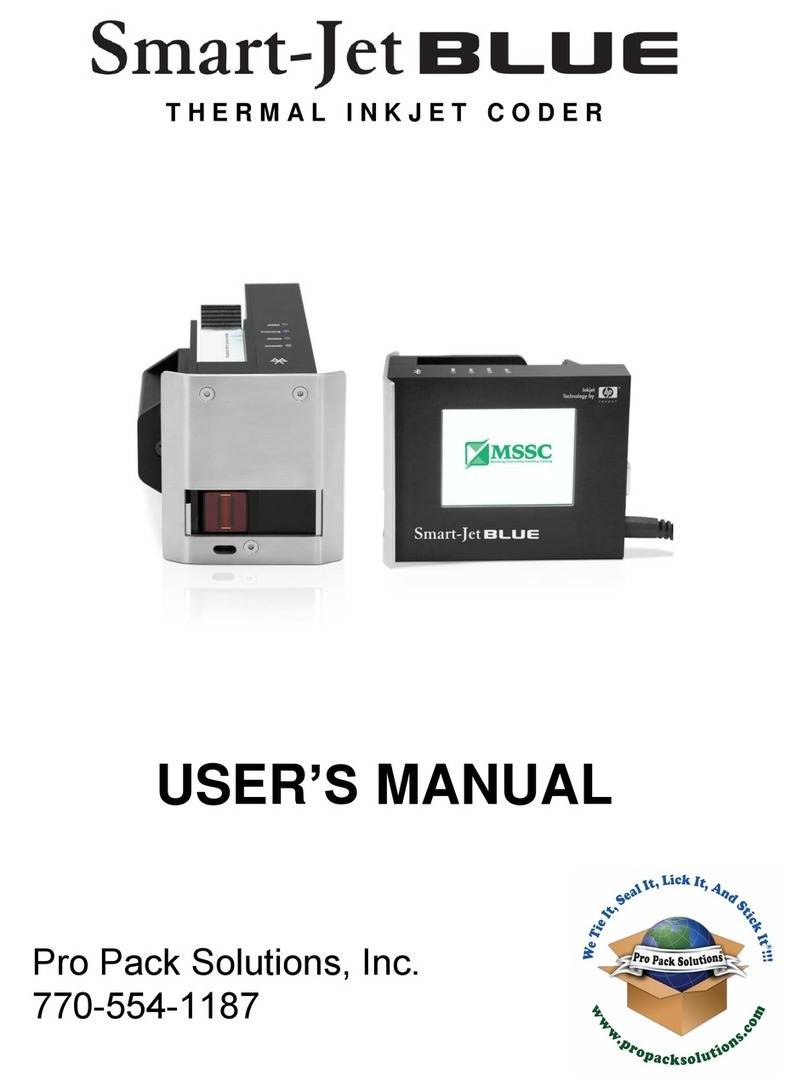

QM1610 Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

About the Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Standard Product Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Chapter 2 — Product Safety

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Chapter 3 — Fast Installation

Printer Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Standard Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

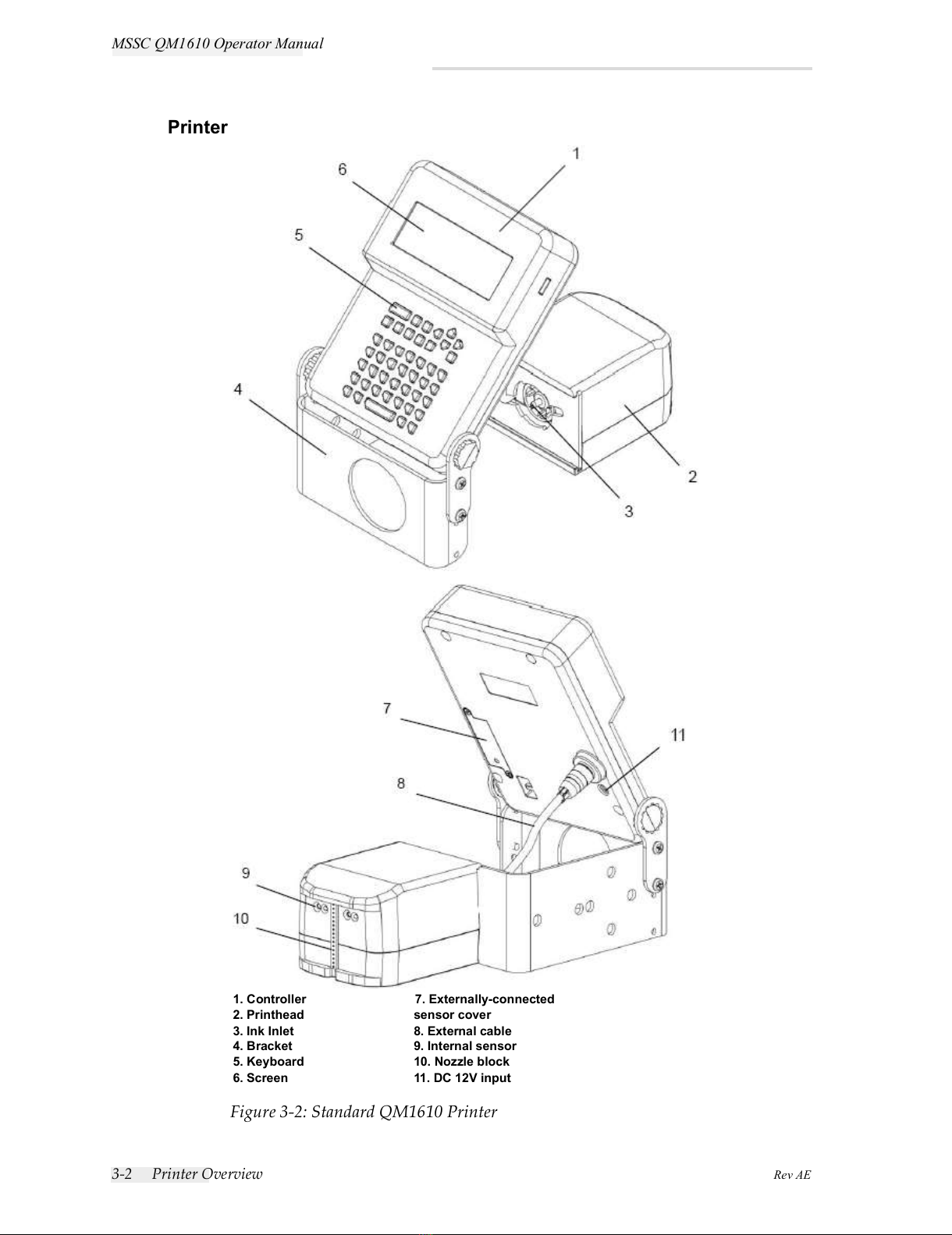

Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Fast Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Installation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Chapter 4 — Operation and Setup

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Keyboard Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Print On/Off. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Dot Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Purge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Print Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Character Width. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Date . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Count Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Number/Special Character Key Lock . . . . . . . . . . . . . . . . . . . . . . 47

Backspace/Delete . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Exit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Input Method Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Capital Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Start Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Main Menu Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Chapter 5 — Maintenance

Frequently Used Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Maintenance of the Keyboard and the