1

MSSC, LLC Collinsville, IL USA Tel: 618-343-1006 Fax: 618-343-1016 55899 Rev 18210

www.msscllc.com

Table of Contents

Introduction..................................................................................................................................................2

Dimensions and Specifications....................................................................................................................2

Installation....................................................................................................................................................3

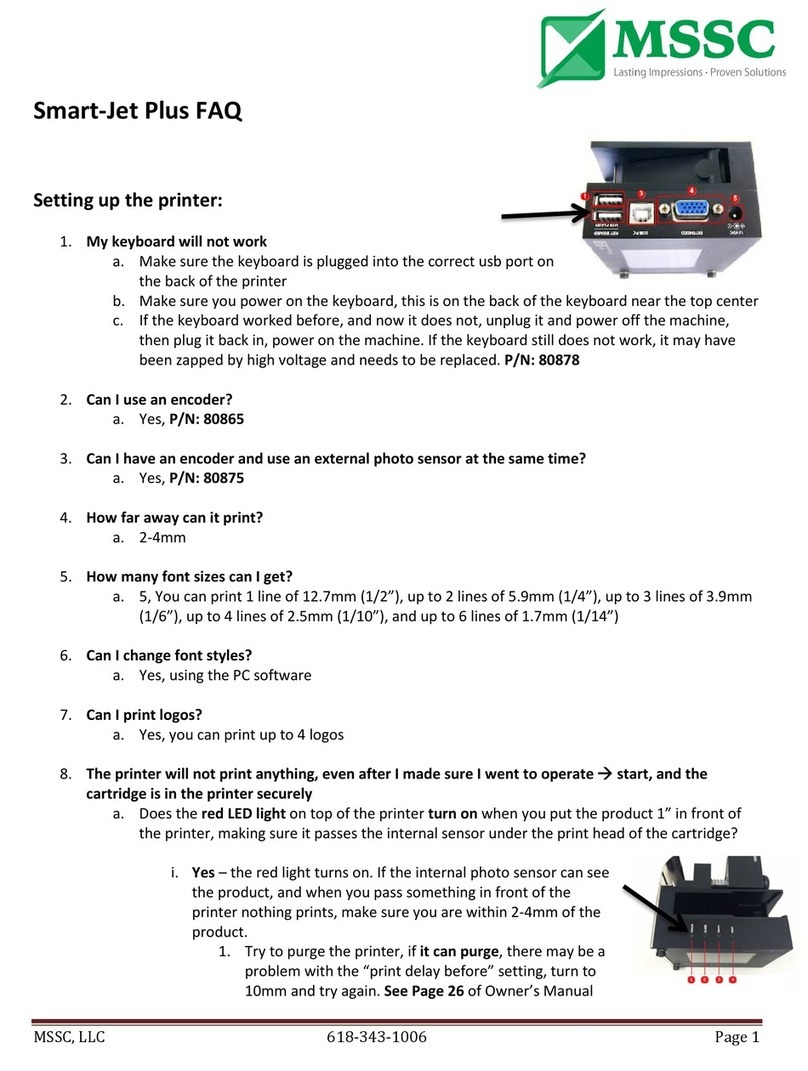

Key Layout...................................................................................................................................................7

Quick Startup...............................................................................................................................................8

Operation....................................................................................................................................................10

Settings.................................................................................................................................................. 10

Menu Language ................................................................................................................................ 10

Setting Date and Time ...................................................................................................................... 10

Setting Format for Date and Time Printing...................................................................................... 10

Expiration Offset............................................................................................................................... 11

Expiration Format............................................................................................................................. 11

Setup Menu........................................................................................................................................... 12

Ink..................................................................................................................................................... 12

Parameter .......................................................................................................................................... 12

DT Tune............................................................................................................................................ 13

Total Count ....................................................................................................................................... 13

Init Data ............................................................................................................................................ 13

Extend............................................................................................................................................... 13

Serial Numbers/Consecutive Numbering ............................................................................................. 14

Editing and Selecting Messages............................................................................................................ 15

Editing/Creating Messages ............................................................................................................... 15

Inputting Special Message Functions ............................................................................................... 15

Inputting Chinese Characters (Available in English menus only).................................................... 16

Two Ways of Printing Two Line Message with the QM2................................................................ 16

Maintenance...............................................................................................................................................18

Installing Ink Cartridges ....................................................................................................................... 18

Cleaning the Print Head........................................................................................................................ 18

Adjusting Screen Contrast .................................................................................................................... 19

Adjusting the Photo Eye ....................................................................................................................... 19

HP Bulk Ink System Setup ........................................................................................................................20

Troubleshooting.........................................................................................................................................25

Appendix....................................................................................................................................................26

Feet/min. to meters/min Conversion Table....................................................................................... 26

Date and Hour Code Table ............................................................................................................... 26

Key Assignments for Characters ...................................................................................................... 27

Sample Message Instructions............................................................................................................ 28

Accessories and Parts........................................................................................................................ 29

Exploded Views and Saleable Parts.................................................................................................. 30

Creating Logos for the QM2............................................................................................................. 33