T H E W O R L D P O W E R I N A N C H O R I N G S Y S T E M S

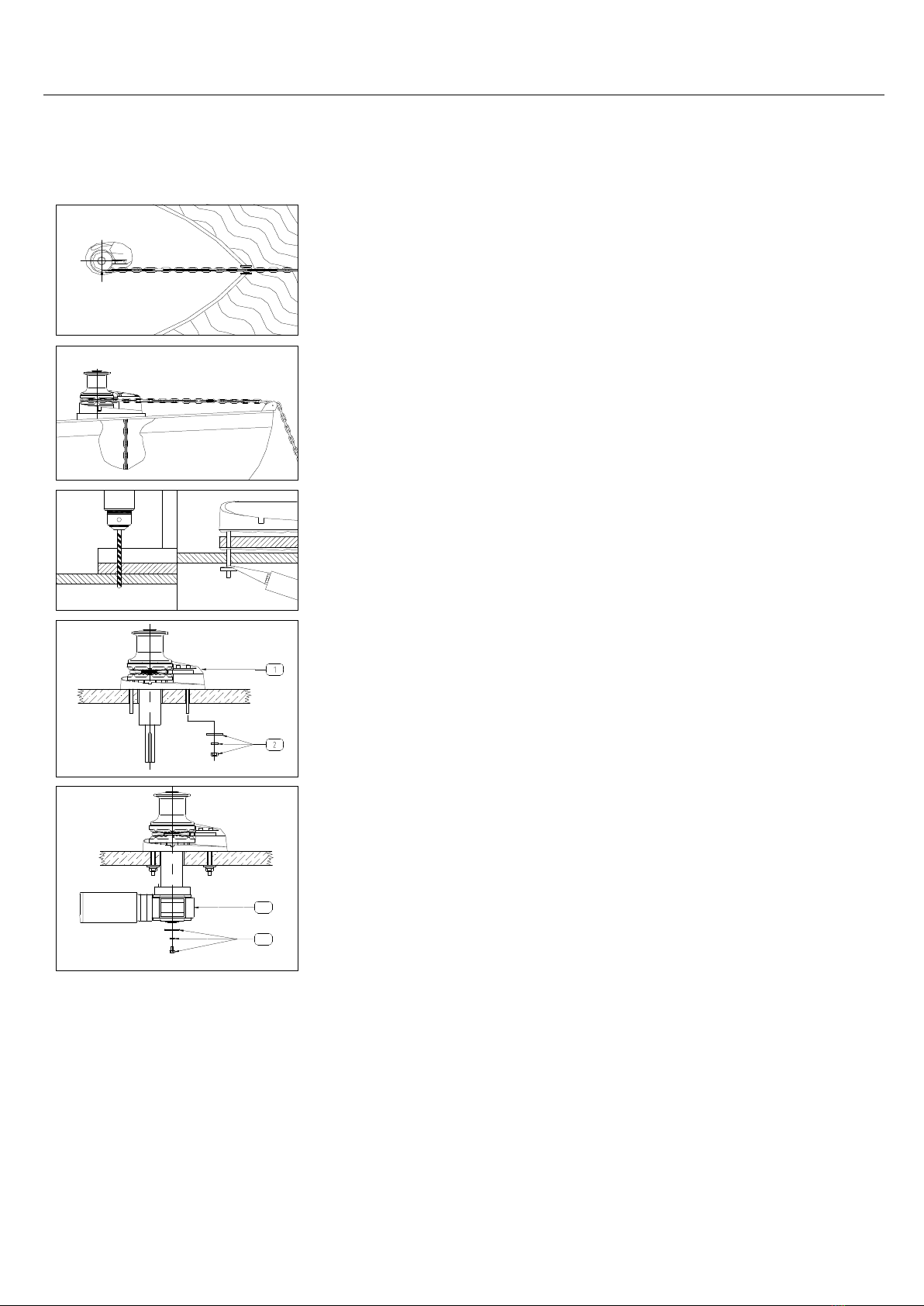

DEPTH OF THE CHAIN LOCKER

Ensuring that the vertical distance, (minimum fall), between the underside of the deck and the top of

the completely stored and heaped anchor rode in the locker will assist in determining the installation to

suit your vessel. Refer to the fall depth diagrams and the options detailed below. It is also

recommended that the chain be directed to the center of the chain locker. (See also water protection

diagram on page 15.)

If your vessel does not meet the minimum fall requirements for a vertical windlass, contact your Muir

retailer.

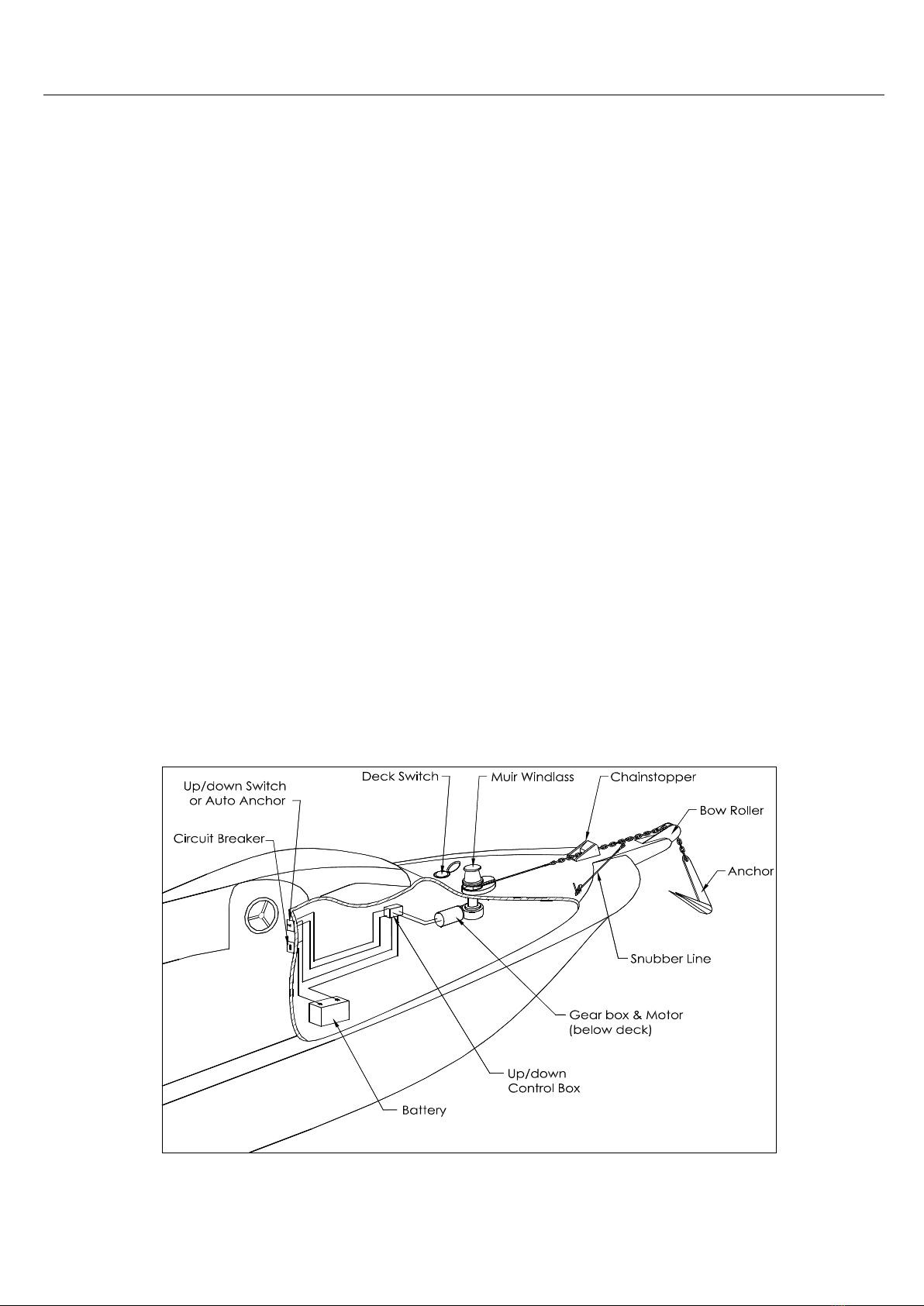

Verti al Windlass: The running gear, gypsy

and capstan are positioned above the

deck with the motor and gear drive

below. Vertical windlasses operate at

best with greater anchor rode fall than

the horizontal windlass and a minimum

fall of 300mm from top of stacked anchor

rode is recommended. This is particularly

important if using nylon line, which does

not fold and stack as well as chain.

Vertical windlasses minimise deck

intrusion and the modern curved lines of

the Muir windlass enhance the look of

any vessel. A vertical windlass provides

the advantages of a I80-degree wrap of

the anchor rode around the gypsy.

Horizontal Windlass: Fully enclosed,

above deck, this style is usually preferred

where locker space is limited or

additional fall is required. The motor and

gear drive is fully enclosed in the housing

with nothing protruding below deck. The

horizontal windlass operates with

optimum anchor rode fall of at least

300mm from the top of the stacked

anchor rode, and due to the horizontal

orientation of the gypsy higher above

the deck there is additional fall provided.

These units are ideally suited for vessels

with less locker space.

Verti al Windlass

Model

Horizontal Windlass

Model

Minimum Fall

(Dist. Top of

Pile)

VR/VRC/VFF 600 R600 - 700 300 mm

VR/C 850 – 1250 & 2200 R1200 450 mm

VR/C 2500 – 3500 R2500 - 3500 650 mm

VR/C 4000 R4000 - 4200 800 mm

VR/VRC/VFF 600 12/01/2015