VRC4500/5000 VERTICAL WINDLASS OPERATION

6

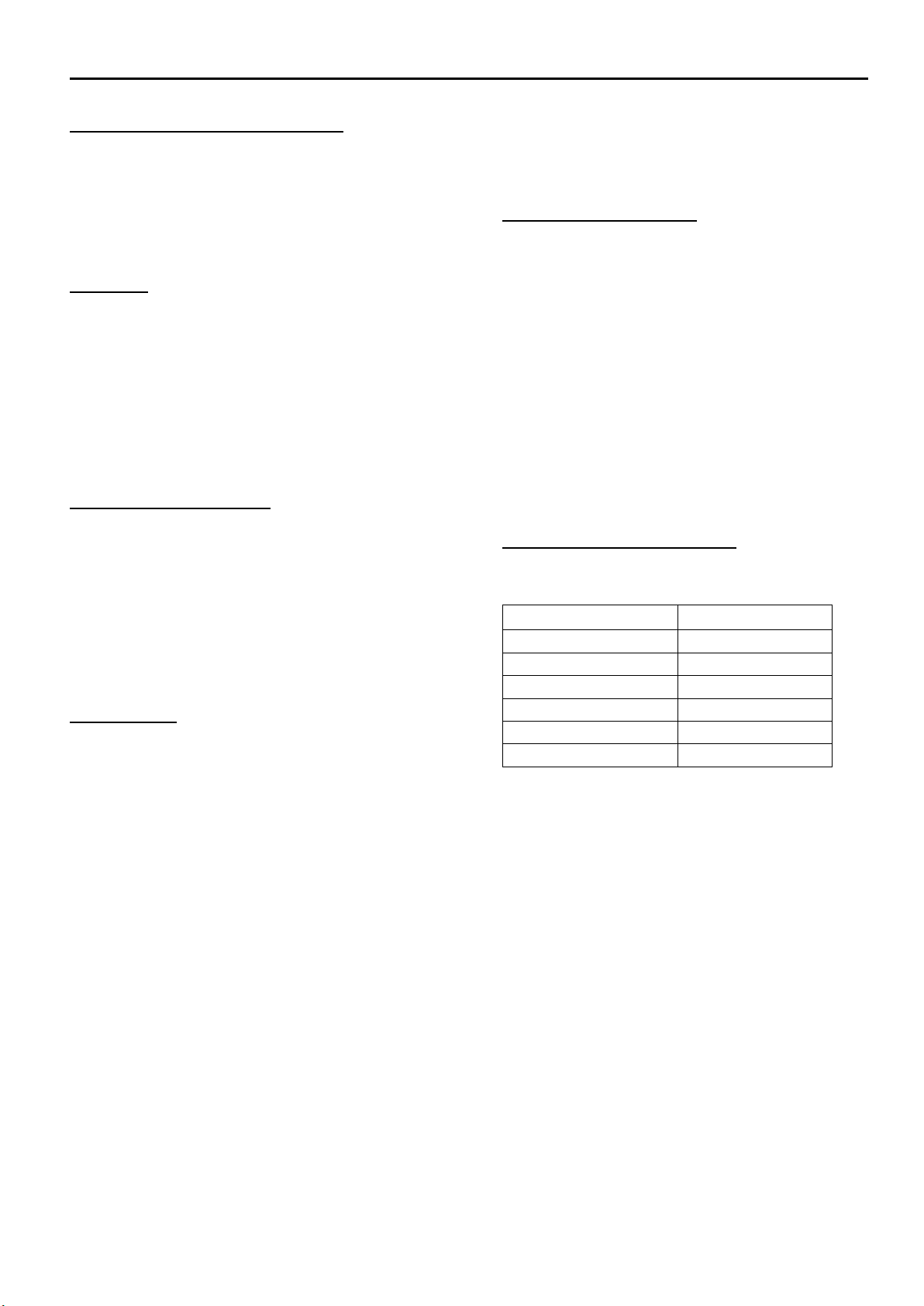

BOLT TORQUES

It is important that all bolts are tightened appropriately to ensure service reliability and structural integrity. The

following are suggested torque/preload values for the general bolt sizes found on Muir Windlasses. Muir also

recommends the use of thread locking compounds on threads to reduce loosening and corrosion.

Bolt Tightening Torque and Pre Load

Stainless Steel Class 70 M8 M10 M12 M16 M20 M24

Tightening Torque (Nm) 16.6 35 61.2 152 296.4 512.8

Pre Load (Nm) 10.8 17.2 25 46.6 72.7 104.8

LOWERING THE ANCHOR

It is important that the windlass operator understands

the operation and safety instructions included before

controlling the equipment supplied to ensure safe,

correct and efficient use. Always keep clear of running

gear and chain when operating.

The windlass can be powered up and down; this gives

the option of using the power system to release the

anchor chain, or by releasing the clutch and controlling

the chain release with the brake band.

Before attempting to lower the anchor by the free

wheel method, apply the brake, ensure the gypsy is

disengaged by rotating the clutch nut in an anti

clockwise direction until the dog clutch is clear. The

chain stopping device can now be disengaged (if

fitted), check the area is clear then proceed to lower

the chain and anchor by slowly releasing the brake

and using the brake to control the rate of descent.

Once the anchor is set at the required depth the brake

must be tightened and the chain stopper must be

engaged to take the load off the windlass while at

anchor.

If powering down, engage the clutch drive by turning

the hand wheel in a clockwise direction until the clutch

is engaged, release the brake band by turning the

handle anti-clockwise.

When using the brake, it is first necessary, after

ensuring the brake is applied (turning the handle

clockwise), to release gypsy drive by rotating the

windlass clutch, with the lever handle, anticlockwise.

This applies to both cone and dog clutch.

A chain stopping device must be fitted forward of the

windlass to take the mooring load off the windlass as

this will result in serious damage being done to the

winch.

By slowly releasing the brake the fall of the anchor can

be controlled. Once the anchor is set at the required

depth the gypsy pawl or chain lock ( if fitted) and brake

band can be tightened. It is recommended that a chain

lock be fitted forward of the windlass to take the load

off the windlass main shaft. Do not leave the anchor

load directly on the running gear as this may result i8n

serious damage to the drive gears. Always ensure the

chain lock then the brake band takes the load in that

order.

If this is not possible use a snubber line forward of the

windlass to take loading off the windlass. Make sure

that the brake is fully engaged while at anchor.

RETRIEVAL

Before lifting the anchor ensure the clutch and brake

are fully engaged and locked into position before

releasing chain securing device. Engage the clutch by

tightening the clutch top (turn the lever handle

clockwise). The anchor can now be raised by

operating the control.

Clutch O eration

To ensure correct engaging of the dog clutch is as

follows:

1. Ensure the four drives are aligned correctly

and will not contact when the clutch is

engaged. This can be done in two ways:

-By utilizing the controls to inch the windlass,

or by using the brake to correctly align the

drive.

2. Engage the drive by turning the clutch nut

clockwise until they are fully engaged.

3. Slowly slacken the brake to allow the gypsy to

rotate. This will allow the faces of the drive to

contact and become fully engaged

4. When engaged the brake may be slackened

fully and windlass operated.

The above functions will allow the drive to be

successfully engaged to operate the windlass in the

recovery operation to retrieve the chain. Should the

windlass be required to lower the chain the above

functions must be reversed.