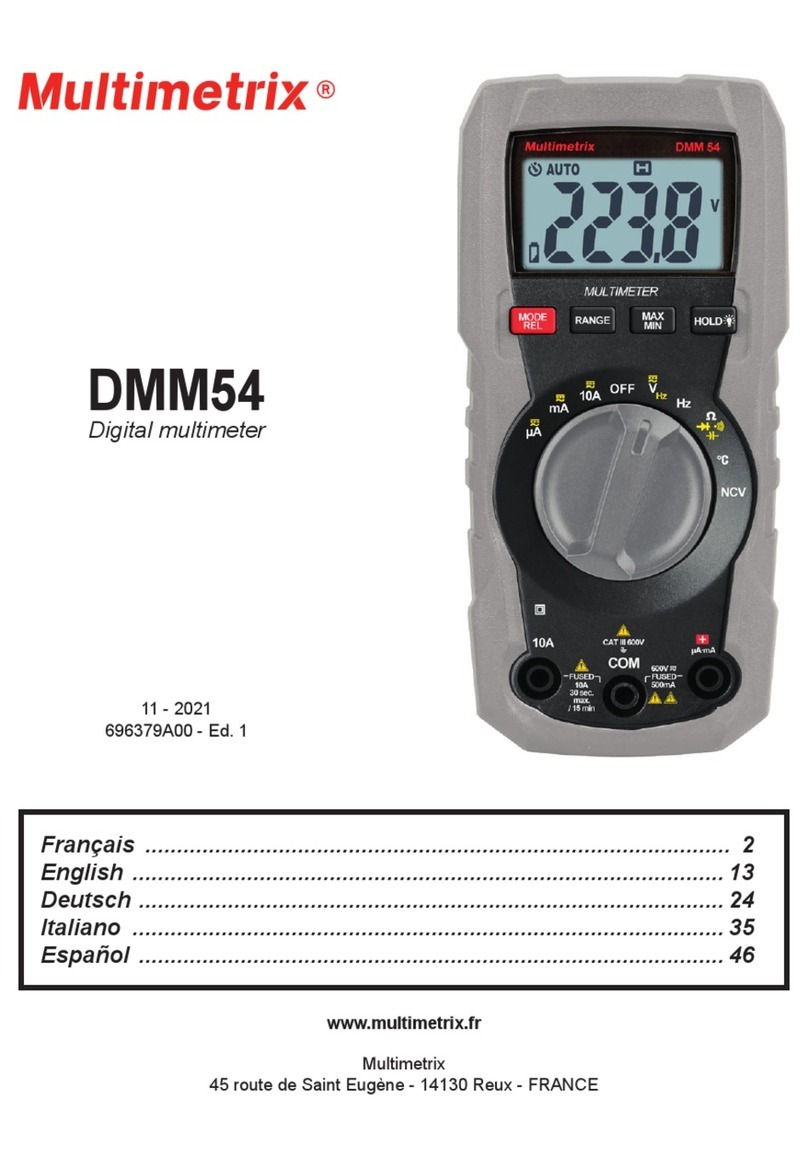

Multimetrix DMM 16 User manual

DMM 16

Multimeter

User’s manual

CHAUVIN ARNOUX

190, rue Championnet

75876 PARIS Cedex 18 -FRANCE

Tel.:+33 1 44 85 44 85 -Fax: +33146 27 7389

info@chauvin-arnoux.fr

Export:Tel.:+33 1 44 85 44 38 -Fax: +33146 27 9559

export@chauvin-arnoux.fr

694243A02-Ed. 4-07/14

PRECAUTIONS FOR USE

This device is compliant with safety standards IEC61010-1, 61010-2-032 and 61010-2-033 for

voltages up to 300V incategory III atan altitude below 2,000m, indoors, witha degree of pollution

of not more than2.

These safety instructions are intended to ensure the safety of persons and proper

operation of the device. If the device is used other than as specified in this data sheet, the

protection provided by the device may be impaired.

The operator and/or the responsible authority must carefully read and clearly

understand the various precautions to be taken in use.

If you use this instrument other than as specified, the protection it provides may be

compromised, thereby endangering you.

Do not use the instrument in an explosive atmosphere or in the presence of

flammable gases or fumes.

Do notusethe instrument on networks of whichthe voltage or categoryexceeds

those mentioned.

Do not exceed the rated maximum voltages between terminals or with respect to

earth.

Do not use the instrument if it seems to be damaged, incomplete, or poorly closed.

Before each use, check the condition of the insulation on the leads, housing, and

accessories. Any item of which the insulation is deteriorated (even partially) must

be set aside for repair orscrapping.

Use leads and accessories rated for voltages and categories at least equal to

those of the instrument. If not, an accessory of a lower category reduces the

category of the combined multimeter + accessory to that of the accessory.

Observe the environmental conditions of use.

Do not modify the instrument and do not replace components with "equivalents".

Repairs and adjustments must be done by approved qualified personnel.

Replace the battery as soon as the symbol appears on the display unit.

Disconnect all leads before opening the battery compartment cover.

Use personal protective equipment when conditions require.

Keep your hands away from the unused test probes of the device.

When handling the test probes, crocodile clips, and current sensor, keep your

fingers behind the physical guard.

Disconnect the test probes from the measurement circuit to make current

measurements.

Disconnect the test probes from the measurement circuit before changing

functions.

MEASUREMENT CATEGORIES

CAT II: Circuits directly connected to the low-voltage installation.

Example: power supply to electro-domestic devices and portable tools.

CAT III: Power supply circuits in the installation of the building.

Example: distribution panel, circuit-breakers, machines or fixed industrial devices.

CAT IV: Circuits supplying the low-voltage installation of the building.

Example: power feeders, counters and protection devices.

- 1 -

You have just acquired a DMM16 multimeter and we thank you for your confidence.

For best results from your instrument:

Read these operating instructions carefully;

Comply with the precautions for use.

Risk ofdanger. The operator agreesto refer tothese instructions

whenever this danger symbol appears.

Application or withdrawal authorized on uninsulated or bare conductors at

dangerous voltages.

Battery

The CE marking indicates conformity with European directives.

Double insulation or reinforced insulation.

Selective sorting of wastes for the recycling of electrical and electronic

equipment within the European Union. In conformity with directive WEEE

2002/96/EC: this equipment must not be treated as household waste.

DC– Direct current

AC– Alternating current

AC and DC– Alternating and direct current

Earth

Risk of electric shock

Instructions that must be read and understood

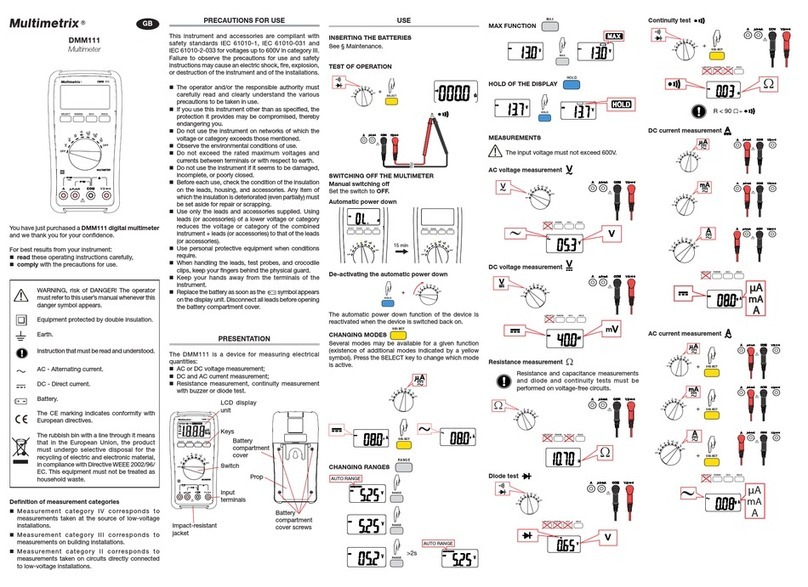

1. PRESENTATION

Le DMM16 is an instrument for measuring electrical quantities that groups the following

functions:

AC or DC voltage measurement;

Frequency measurement;

Resistance measurement, continuity measurement with buzzer, or diode test;

Capacitance measurement;

DC or AC current measurement;

- 2 -

1.1 The switch

The switch has six positions. To access the various functions, set the switch to the

corresponding positions. Each active position is confirmed by an audible signal. The

functions are described in the table below.

OFF Stop

V or V /Hz AC or DC voltage measurement/Frequency

measurement

/ / Resistance measurement, continuity

measurement with buzzer, or diode test

Capacitance measurement

120A/

120A/Hz

120A DC or AC current measurement/

Frequency measurement

60A

/

60A/Hz

66A DC or AC current measurement/

Frequency measurement

1.2 The keys of the keypad

-"SEL" (SELECT) key

Press the "SEL" key repeatedly to obtain the following functions according to the setting

of the rotary switch:

V /V DC voltage/AC voltage

/ / Resistance measurement/continuity

measurement/diode test

120A/ 120A 120A DC current measurement/120A AC current

measurement

60A/ 60A 66A DC current measurement/66A AC current

measurement

-"RANGE" key

Your multimeter has a range change function that is normally automatic but can be made

manual. When the instrument is switched on, the default mode is automatic range

change: the "AUTO" message is then displayed.

Briefly press the "RANGE" key to change to manual mode: the "AUTO" message is

then replaced by "MANU".

Successive brief presses are used to reach the desired range.

Hold the "RANGE" key down for 2 seconds to return to the automatic range change

mode: the "MANU" message reverts to "AUTO".

- 3 -

Choice of ranges (or ratings) according to function:

660.0mV/6.600V/66.00V/600.0V

660.0mV/6.600V/66.00V/600.0V

Ω

660.0Ω

6.600kΩ/66.00kΩ/660.0kΩ

6.600MΩ/66.00MΩ

6.600nF/66.00nF/660.0nF

6.600μF/66.00μF/660.0μF/6.600mF/66.00mF

-"HOLD" key

In the "HOLD" mode, the device freezes the display ofthe lastvalue measured.

Pressing the "HOLD" key briefly during a measurement freezes the display: the

message is then displayed.

A second brief press on the "HOLD" key is used to return to the normal measured

value display refresh mode: the message disappears from the display unit.

-"MAX MIN" key

In the "MAX MIN" mode, the device records the maximum and minimum values of the

measurements made. In this mode, the automatic range change does not change the

range when this mode is entered; if the maximum values exceed the display range

(indicated by the "OL" message), the appropriate higher range must be chosen manually

before reactivating the "MAX MIN" mode.

Successive brief presses on the "MAX MIN" key produce, in order, the following actions:

1st press: the device records and displays the maximum value measured. The

"AUTO" messageis replacedby "MANU"and the "MAX" message is displayed.

2nd press: the device records and displays the minimum value measured; the "MAX"

message is replaced by "MIN".

3rd press: the device records the maximum and minimum values measured

simultaneously; it is the value currently measured that is displayed; the "MAX" and

"MIN" messages blink simultaneously on the display unit.

Additional presses serve to display the values recorded one by one by reproducing the

actions of the previous successive presses.

Press the "MAX MIN" key for two seconds to exit from the mode: the "MANU", "MAX",

and "MIN" messages are replaced by "AUTO", indicating that the device once again

changes range automatically.

-"Hz" (Hertz) key

Press the "Hz" key briefly and repeatedly to obtain the following functions according to

the settingof the rotary switch:

AC voltage measured/Frequency/Duty cycle

DC voltage measured/Frequency/Duty cycle

- 4 -

120 120A AC current measured/Frequency/Duty cycle

60 66A AC current measured/Frequency/Duty cycle

NB: When the duty cycle measurement is activated, the automatic range change leaves

the range unchanged when the mode is entered: the device changes to manual range

change mode and the "MANU" message is displayed.

- " " (Backlight) key

A brief press on the "Backlight" key lights or switches off the display unit backlighting. If

not reactivated, the backlighting switches itself off automatically after approximately 60

seconds.

"REL (ZERO)" key

The "REL (ZERO)" key is used to subtract the value displayed when the key is pressed

from all subsequent measurement values and display the result of the subtraction.

This mode can be activated by a brief press on the key for all functions except the

frequency and duty cycle measurements.

When display in relative mode is activated, the automatic range change leaves the range

unchanged when the mode is entered: the device changes to manual range change

mode and the "MANU" and " " messages are displayed.

For DC current measurements, this mode is used to set the display to zero before the

current sensor is placed on the conductor in which the current is to be measured; the

message displayed for this function, in this mode, is "ZERO".

Another brief press on the key effects the return to the normal display mode; the device

returns to the automatic range change mode and the "MANU" and " " messages are

replaced by the "AUTO" message.

Any change of function by the rotary switch terminates display in the relative mode.

1.3 The display unit

- 5 -

Symbol

Description

AUTO

Automatic range change

MANU

Manual range change

(Data Hold) Freezes the display

Value displayed in relative mode

Display of the maximumand minimumvalues

ZERO

Reset forDC current measurements

Diode test function

Continuity test function

%

Unit and function Duty cycle

APO

(Auto Power Off) automatic switching off activated

DC measurement and display

AC measurement and display

Display of a negative value

Low battery indicator (battery must be replaced)

V

(Volt) unit of voltage

A

(Ampere) unit of current

(milliFarad, nanoFarad, microFarad) units of capacitance

(ohm, kilo-ohm, Megohm) unit of resistance

Hz

(Hertz) unit of frequency

The "OL" message (OverLoad) indicates an overshoot of the measurement or display

capacity.

1.4 The leads and test probes

The multimeter is equipped with two leads (red and black), each terminated by a test

probe of thesame colour.

The leads and test probes are not detachable (they are permanently connected) and,

when not in use, can be stowed in the compartments provided for them on the right side

of the device.

The tips of the test probes (once taken out of their compartments by pressing on them

with a finger), allow voltage, resistance, continuity, diode test, and capacitance

measurements.

The test probes have physical guards that show the operator where the hand grip part

ends, beyond which the fingers must not be placed.

1.5 The current sensor

The multimeter has a current sensor that makes it possible to measure a current without

having to open the circuit.

The current sensor and its lead cannot be detached (they are permanently connected);

when not in use, they can be stowed in compartments provided for them on the back of

the device.

The current sensor has a physical guard that shows the operator where the hand grip

part ends, beyond which the fingers must not be placed.

- 6 -

2. USE

2.1 Commissioning

Place the batteries supplied with the device as follows:

1. Using a cross-headed screwdriver, unscrew the screw of the compartment cover

on the back of the housing and open the cover;

2. Place the 2 batteries in their compartment, with the correct polarities;

3. Close the cover and screw it back to the housing.

2.2 Starting up and check of operation

We recommend performing this procedure at the time of commissioning and, if the device

is used only occasionally, each time it is used.

Hold the "HOLD" key down and switch the instrument on by turning the switch from

"OFF" to "Ω".

Release the "Hold" key and check that the various symbols and segments are

correctly displayed.

A brief press on the "HOLD" key restores the normal display of the selected

function;

If the device is set to the resistance measurement function ("Ω"), check that the

display indicates "A.P.O" (for auto power off), "AUTO" (for automatic range

change), "O.L" (for OverLoad), and"MΩ" (for Megohm);

Withdraw the two leads from their compartment and establish a good contact

between the metallic parts of the two test probes; the value measured and

displayed must change from "O.LMΩ" to "0.0Ω": (the value displayed may not

be exactly zero, but must remainveryclose to zero).

The instrument is operational when the various states described above have been

checked and are correct. The rotary switch can then be set to the desired function

or to "OFF" to switch the instrument off.

- 7 -

2.3 Deactivating Auto Power Off

In order to extend the life of the batteries, the device switches itself off automatically

approximately 15 minutes after it is switched on if no key or change of function has

been activated. The device warns that it is about to switch off by emitting 3 series of 2

audible beeps and, if no action is taken, then emits a long beep and switches itself off.

When the multimeter switches itself off automatically, it can be restarted in the same

configuration by pressing the "HOLD" key twice. Any other action restarts the device,

but changes its configuration.

Automatic switching off can be deactivated by holding down the "Hz", "REL", "MAX

MIN", "RANGE" or "Backlight" key while switching on. Reminder: automatic switching

off is deactivated when the instrument is in the "MAX MIN" mode.

To eliminate the slight residual drain of the batteries in the sleep mode, it is always

best to switch the device "OFF".

2.4 DC current measurement (A )

For optimum safety, current measurements oncircuitsat voltages between 300V and

600V must be made only on category III installations or on circuits of which the possible

overvoltage levels are known to be less than those of category III.

The current sensor must not be used at the same time as the test probes.

The instrument has 2 measurement ranges, selected using the rotary switch (60A and

120A).

Remove the current sensor from its compartment on the back of the device (the test

probes are stowed in their own compartment.

Switch the instrument on in the 60A or 120A setting.

Let the value displayed stabilize and briefly press the "REL (ZERO)" key to set the

value displayed to zero. It is often necessary to repeat this operation after measuring

strong currents.

Place the sensor on the cable as indicated by the locating marks (the sensor must be

perpendicular to the cable on which it is placed), see the figure below.

Read the measurement result (afterstabilization).

Display of the "-" sign in front of the numerical value indicates that the value measured

is negative: the current is flowing in the direction opposite the polarities indicated on

the sensor.

Note: best results are obtained when the cable is carefully centred and any nearby cables

are held away fromit.

- 8 -

2.5 AC current measurement (A )

For optimum safety, current measurements oncircuitsat voltages between 300V and

600V must be made only on category III installations or on circuits of which the possible

overvoltage levels are known to be less than those of category III. The current sensor

must not be used at the same time as the test probes. The instrument has 2

measurement ranges, selected using the rotary switch (60A and 120A).

Remove the current sensor from its compartment on the back of the device (the test

probes are stowed in their own compartment.

Switch the instrument on in the 60A or 120A setting.

Press the "SEL"key briefly to switch to AC current measurement; the " " symbol is

displayed instead of " ";

Place the sensor on the cable as indicated by the locating marks (the sensor must be

perpendicular to the cable on which it is placed), see the figure above.

Read the measurement result (after stabilization).

Note: best results are obtained when the cable is carefully centred and any nearby cables

are held away from it.

2.6 DC voltage measurement (V )

For optimum safety, current measurements oncircuitsat voltages between 300V and

600V must be made only on category III installations or on circuits of which the possible

overvoltage levels are known to be less than those of category III. The instrument has 4

measurement ranges: 660mV, 6,6V, 66V, 600V. The 600mV range can be used only in

the manual range change mode, by repeated presses on the "RANGE" key. The other

ranges can be usedineitherthe manual orthe automatic range change mode.

Withdraw the test probes and leads from their compartment.

Switch the instrument on in the "V" setting.

Apply the metallic part of the black test probe on the (assumed) negative part of the

circuit to be tested.

Apply the metallic part of the red test probe on the (assumed) positive part of the

circuit to be tested.

Read the measurement result (afterstabilization).

Display of the "-" sign in front of the numerical value indicates that the value measured

is negative (the testprobesare reversed withrespect tothe polarity ofthe voltage).

2.7 AC voltage measurement (V )

For optimum safety, current measurements oncircuitsat voltages between 300V and

600V must be made only on category III installations or on circuits of which the possible

overvoltage levels are known to be less than those of cat. III. The DMM16 has 4

measurement ranges: 660mV, 6,6V, 66V, 600V.

The 600mV range can be used only in the manual range change mode, by repeated

presses on the "RANGE" key. The other ranges can be used in either the manual or the

automatic range change mode.

Withdraw the test probes and leads from their compartment.

Switch the instrument on in the "V" setting.

Press the "SEL"key briefly to switchto AC voltage measurement (the " " symbol is

displayed instead of " ")

Apply the metallic part of the black testprobe onthe partof the circuit to be tested

(assumed) closest to the earth potential.

Apply the metallic part of the redtest probe on the partof the circuit to be tested

(assumed) farthest from the earth potential.

Read the measurement result (after stabilization).

- 9 -

2.8 Frequency measurement (Hz)

For optimum safety, current measurements oncircuitsat voltages between 300V and

600V must be made only on category III installations or on circuits of which the possible

overvoltage levels are known to be less than those of category III.

The instrument has 3 measurement ranges: 660,0Hz, 6,600kHz and 66,00kHz.

Measurement of the frequency of the voltage measured: start the AC voltage

measurement method, then press the "Hz" key (display of the "Hz" symbol instead of "V").

Measurement of the frequency of the current being measured: start the AC current

measurement method, then press the "Hz" key (the "Hz" symbol is displayed instead

of "A";

Read the measurement result afterstabilization.

2.9 Duty cycle measurement (%)

For optimum safety, current measurements oncircuitsat voltages between 300V and

600V must be made only on category III installations or on circuits of which the possible

overvoltage levels are known to be less than those of category III.

The measurement range is from 10% to 94.9% (50-60Hz). If there is no usable signal or if

the duty cycle is less than 10%, the display indicates "UL", and if the duty cycle is greater

than 94.9%, the display indicates "OL".

For voltage duty cycle measurements, the device switches itself to the manual range

change mode.

Measurement of the duty cycle of the voltage being measured: start the AC voltage

measurement method, then press the "Hz" key twice (the "%" symbol is displayed

instead of "V" and "MANU" instead of "AUTO");

Measurement of the duty cycle of the current being measured: start the AC current

measurement method, then press "Hz" twice ("%" is displayed instead of "A");

Read the measurement result afterstabilization.

2.10 Resistance measurement (Ω)

Resistance, continuity, diode test, and capacitance measurements must be made

only on circuits completely disconnected fromany power supply, andafter any capacitors

have been discharged.

The instrument has 6 measurement ranges: 660,0Ω, 6,600kΩ, 66,00kΩ, 660,0kΩ,

6,600MΩ and 66,00MΩ.

All of the ranges can be used with either automatic or manual range change.

Withdraw the test probes and leads from their compartment.

Switch the instrument on in the "Ω" setting.

Apply the metallic tips of the test probes to the terminals of the resistance or of the

circuit to be tested

Read the measurement result (afterstabilization).

NB: Touching the elements or circuit during the measurement may lead to erroneous

results. For resistance measurements on nonlinear circuits, it may be necessary to select

the measurement mode and the range to be usedmanually.

- 10 -

2.11 Continuity measurement (Ω)

Resistance, continuity, diode test, and capacitance measurements must be made

only on circuits completely disconnected fromany power supply, andafter any capacitors

have been discharged.

The instrument indicates continuity by emitting a steady sound when the resistance

measured is less than 50Ω.

The value displayed is the value measured in ohms.

Withdraw the test probes and leads from their compartment.

Switch the instrument on in the "Ω" setting.

Press the "SEL" key briefly until " " appears.

Apply the metallic tips of the test probes to the terminals of the resistance or of the

circuit to be tested.

Read (if necessary) the measurement result (afterstabilization).

2.12 Diode measurement (Ω)

Resistance, continuity, diode test, and capacitance measurements must be made

only on circuits completely disconnected fromany power supply, andafter any capacitors

have been discharged.

The instrument indicates the voltage across the terminals of the semiconducting junction.

Take out the test probes and leads.

Switch the instrument on in the "Ω" setting.

Press the "SEL" key briefly until the " " symbol appears

Apply the metallic tips ofthe test probes to the terminals of the diode or ofthe junction

to be tested, according to the following polarities;

1) forward direction (conducting): apply the black probe to the cathode and the red

probe to the anode.Readthe measurement result (after stabilization), see figure A

(the threshold voltage of a silicon diode is between 0.5V and 0.7V; it is between 0.2

and 0.3V for a germanium diode. High-voltage diodes, some Zener diodes, and LEDs

cannot be tested by this method).

2) reverse direction (non-conducting): apply the black probe to the anode and the red

probe to thecathode. Read the measurement result (after stabilization), see figure B

(a diode or junction in good condition causes the display of "OL").

With some types of diode, a measured value outside the stated voltage ranges does

not necessarily mean that the diode or junction is defective.

3. CHARACTERISTICS

3.1 General conditions

Temperature

23°C ± 2°C

Relative humidity

45% to 75%

Supply voltage

2,8V ± 0.3V

Frequency range of the applied signal

45-65Hz

Sine wave

pure

Peak factor of the applied AC signal

√2

Position of the conductor in the sensor

centred

Adjacent conductors

none

AC magnetic field

none

Electric field

none

- 11 -

3.2 Characteristics under the conditions of use

Display rate:approximately 3 measurements per second

The uncertainties are expressed in ± (x% L+y digit)

DC current measurement

Range

Resolution

Measurement uncertainties

Input resistance

66.00A

0.01A

2.0% +10

─

120.0A

0.1A

2.0% +5

AC current measurement

Range Resolution

Measurement uncertainties

Input resistance

45~400Hz

66.00A

0.01A

2.0% +5 ─

120.0A

0.1A

DC voltage measurement

Range

Resolution

Measurement uncertainties

Input resistance

660.0mV

0.1mV

1.0% +3 approx. 10MΩ

6.600V

0.001V

66.00V

0.01V

600.0V

0.1V

AC voltage measurement

Range Resolution

Measurement uncertainties

Input resistance

45~60Hz

60~400Hz

660.0mV

0.1mV

1.5% +5

-

approx. 10MΩ

6.600V

0.001V

1.5% +5

66.00V

0.01V

600.0V

0.1V

Resistance measurement

Range Resolution Measurement

uncertainties

Voltage

maximum

applicable

660.0Ω

0.1Ω

1.0% +5 600V

6.600kΩ

0.001kΩ

66.00kΩ

0.01kΩ

660.0kΩ

0.1kΩ

6.600MΩ

0.001MΩ

2.0% +5

66.00MΩ

0.01MΩ

3.0% +5

Continuity measurement

Range

Resolution

Observation No-load voltage

660.0Ω0.1Ω

The buzzer is

actuated at values

less than

approximately 50Ω

approx. 0.8V

- 12 -

Diode test

Range

Resolution

Measurement uncertainties

No-load voltage

2.000V

0.001V

1.0%+5

approx. 2.0V

Capacitance measurement

Range

Resolution

Measurement uncertainties

Remarks

6.600nF

0.001nF

2.5% +5 after adjustment of the

zero for the rangesfrom

6.6nF to 6.6µF

66.00nF

0.01nF

660.0nF

0.1nF

6.600μF

0.001μF

66.00μF

0.01μF

660.0μF

0.1μF

6.600mF

0.001mF

3.0% +5

66.00mF

0.01mF

Frequency measurement

Range Resolution

Measurement uncertainties

Remarks

10.0~660.0Hz

0.1Hz

0.1% +5

At values <10.0Hz,

the display indicates

00.0Hz

6.600kHz 0.001kHz 0.1% +3

66.00kHz 0.01kHz

Sensitivity

Range

Minimum input signal (sine wave)

10Hz~400Hz

400.1Hz~10.00kHz

660mV

200mV

400mV

6.6V 0.3V 0.7V

66V

1V

3V

660V

10V

20V

66A 1A 6A

120A 10A 50A

Duty cycle measurement

Range Resolution

Measurement

uncertainties

Remarks

10% ~

94.9% 0.1% 0.5% +5

no signal or a cycle less than 10%

causes the display of "UL";

A cycle greater than 94.9%, causes

the display of "OL".

For a square wave at 50/60Hz

- 13 -

3.3 Environmental conditions

Environmental conditions in use in storage

Temperature 0°C to +50°C

32°F ~ 122°F -10°C to +60°C

14°F~140°F

Relative humidity (RH) ≤80% without

condensation ≤70% without

condensation

Altitude <2.000m up to 10.000m

3.4 Constructive characteristics

Housing Rigid polycarbonate shell with moulded elastomer covering

Sensor Polycarbonate Clamping diameter: 12mm

Screen LCD display unit with blue backlighting

Dimensions: l 41xH 18mm

Dimensions H 130xL 81xP 24mm

Weight 160 g (without battery)

3.5 Supply

Batteries 2x1,5V (AAA)

Mean battery life >250 hours (without backlighting)

Auto power off delay After ≈15 min without action on the switch and/or on

the keys

3.6 Compliance with international standards

Electric safety:

Protection class

Compliant with standards IEC61010-1,

IEC61010-2-32 and IEC61010-2-33

300V CAT III.

Class 2, double insulation

Electromagnetic

compatibility

Compliant with standard EN 61326-1

Level of protection of

the housing

Housing: IP40 (according to the standard IEC60529)

- 14 -

4. MAINTENANCE

The instrument has no parts that can be replaced by personnel who are not trained and

approved. Any non-approved repair or other work, or replacement of a part by an

"equivalent", may severely compromise safety.

4.1 Cleaning

- Disconnect the unit completely and turn the rotary switch to OFF.

- Use a soft cloth, dampened with soapy water. Rinse with a damp cloth and dry rapidly

with a dry cloth or forced air.

- Dry perfectly before putting back into use.

4.2 Replacement of the batteries

The symbol indicates that the batteries are spent. When this symbol appears on

the display unit, the batteries must be replaced. The measurements and specifications

are no longer guaranteed.

To replace the batteries,proceed as follows:

1. Disconnect everything connected to the device;

2. Set the switch to OFF;

3. using a cross-headed screwdriver, unscrew the screw of the battery compartment

cover on the back of the housing and open the cover;

4. Always replace both batteries;

5. Close the cover and screw it back down.

4.3 Repair

Return the instrument to your distributor for any work to be done, whether under the

warranty or not. If you have to ship the instrument, it is best to use its original packaging

and to state as clearly as possible, in a note attached to the equipment, the reasons for

the transfer.5. WARRANTY

The equipment is warranted against defects of materials or workmanship, in accordance

with the general terms of sale. During the warranty period (1 year), the instrument must

be repaired only by the manufacturer, who reserves the right to choose between repairing

it or replacing it, entirely or partially. If the equipment is sent back to the manufacturer,

carriage is paid by the customer

The warranty does not apply in the following cases:

1. Inappropriate use of the equipment or use with incompatible equipment;

2. Modifications made to the equipment without the explicit permission of the

manufacturer’s technical staff;

3. Work done on the device by a person not approved by the manufacturer;

4. Adaptation to a particular application not anticipated in the definition of the

equipment or not indicated in the user’s manual;

5. Damage caused by shocks, falls, or floods;

6. DELIVERY CONDITION

The DMM16 multimeter is delivered in a blister pack with:

2 1.5V batteries

a user manual in several languages

- 15 -

Table of contents

Other Multimetrix Multimeter manuals

Multimetrix

Multimetrix DMM53 User manual

Multimetrix

Multimetrix DMM54 User manual

Multimetrix

Multimetrix DMM 13 User manual

Multimetrix

Multimetrix CM 605 User manual

Multimetrix

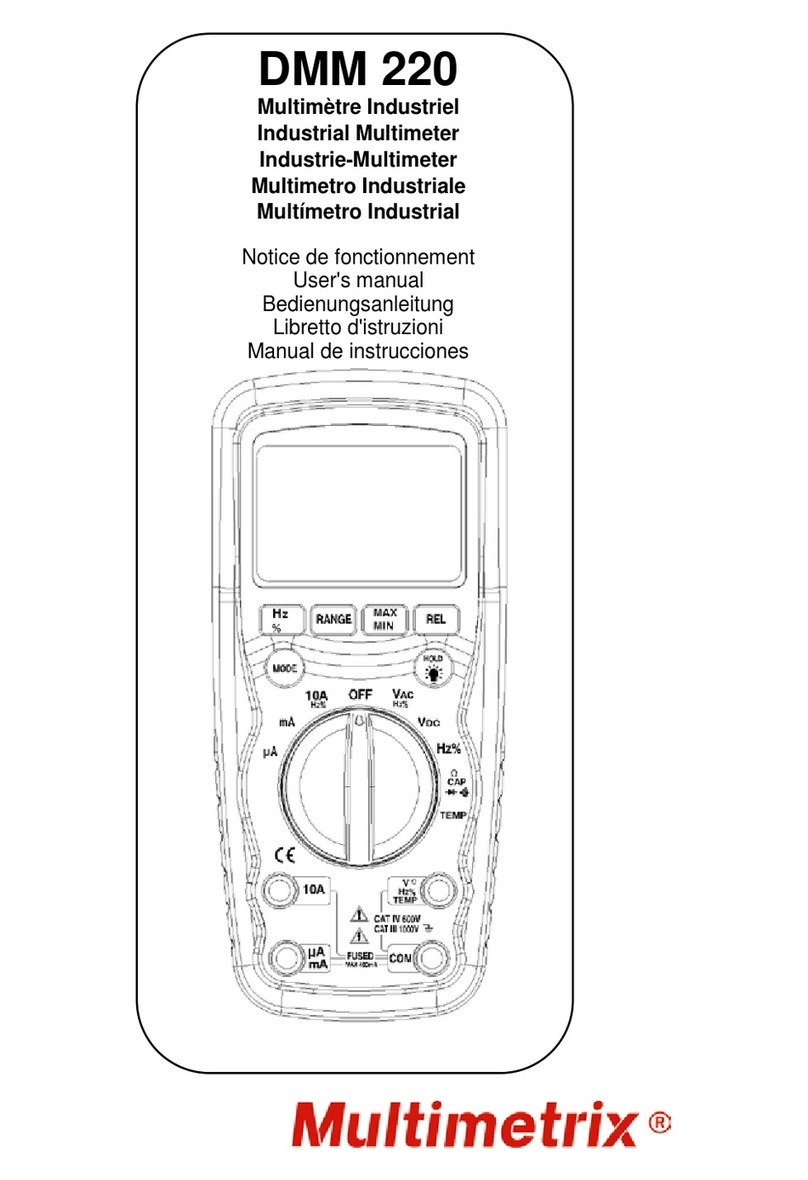

Multimetrix DMM 220 User manual

Multimetrix

Multimetrix DMM 230 User manual

Multimetrix

Multimetrix DMM 107 User manual

Multimetrix

Multimetrix DMM121 User manual

Multimetrix

Multimetrix CM603 User manual

Multimetrix

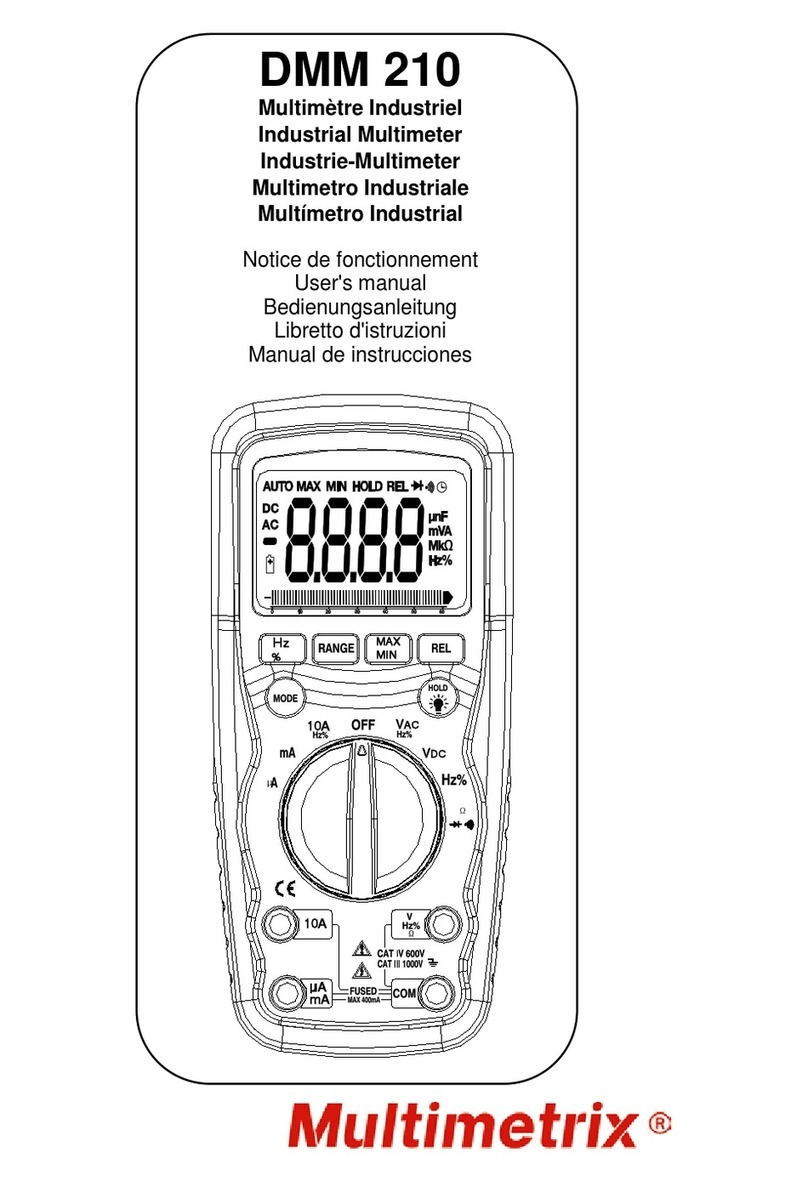

Multimetrix DMM 210 User manual