MFM - 13MULTI FUNCTION METERMECHANICAL INSTALLATION GUIDELINES

1. Prepare the panel cutout with proper dimensions as shown above. 2. Fit the unit into the panel with the help of clamp given. 3. The equipment in its installed state must not come in close proximity to any heating source, caustic vapors, oils steam, or other unwanted process byproducts. 4. Use the specified size of crimp terminal (M3.5 screws) to wire the terminal block. Tightening the screws on the terminal block using the tightening torque of the range of 1.2 N.m. 5. Do not connect anything to unused terminals.

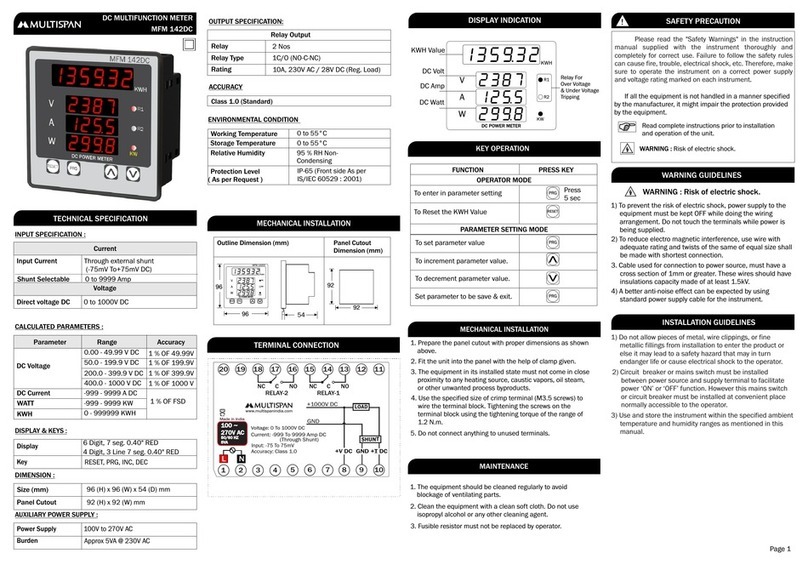

INSTALLATION GUIDELINES

1. This equipment, being built-in-type, normally becomes a part of main control panel and in such case the terminals do not remain accessible to the end user after installation and internal wiring.

2. Do not allow pieces of metal, wire clippings, or fine metallic fillings from installation to enter the product or else it may lead to a safety hazard that may in turn endanger life or cause electrical shock to the operator. 3. Circuit breaker or mains switch must be installed between power source and supply terminal to facilitate power ‘ON’ or ‘OFF’ function. However this mains switch or circuit breaker must be installed at convenient place normally accessible to the operator. 4. Use and store the instrument within the specified ambient temperature and humidity ranges as mentioned in this manual.

MAINTENANCE

1. The equipment should be cleaned regularly to avoid blockage of ventilating parts. 2. Clean the equipment with a clean soft cloth. Do not use isopropyl alcohol or any other cleaning agent.3. Fusible resistor must not be replaced by operator.

Read complete instructions prior to installation and operation of the unit. WARNING : Risk of electric shock.

SAFETY PRECAUTION!

All safety related codifications, symbols and instructions that appear in this operating manual or on the equipment must be strictly followed to ensure the safety of the operating personnel as well as the instrument. If all the equipment is not handled in a manner specified by the manufacturer, it might impair the protection provided by the equipment.

WARNING GUIDELINESWARNING : Risk of electric shock.

1. To prevent the risk of electric shock, power supply to the equipment must be kept OFF while doing the wiring arrangement. Do not touch the terminals while power is being supplied.

2. To reduce electro magnetic interference, use wire with adequate rating and twists of the same of equal size shall be made with shortest connection. 3. Cable used for connection to power source, must have a cross section of 1mm or greater. These wires should have insulations capacity made of at least 1.5kV. 4. A better anti-noise effect can be expected by using standard power supply cable for the instrument.

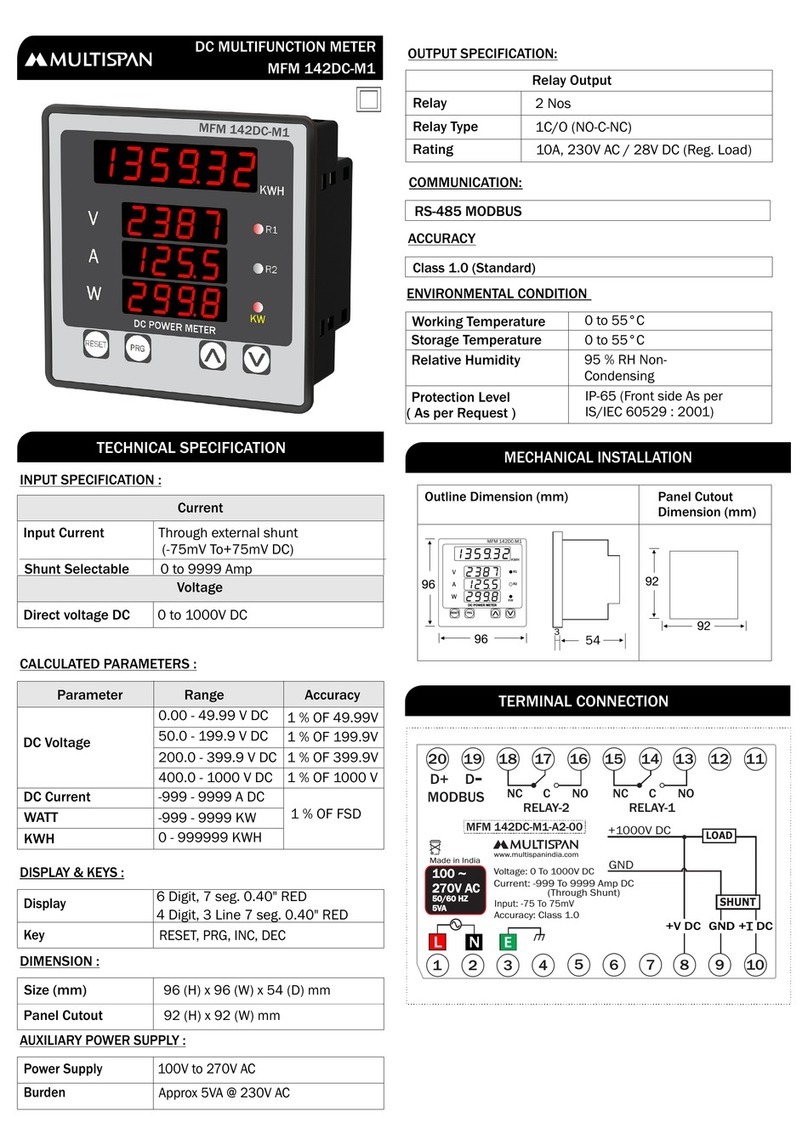

MECHANICAL INSTALLATIONPARAMETER MEASUREMENT

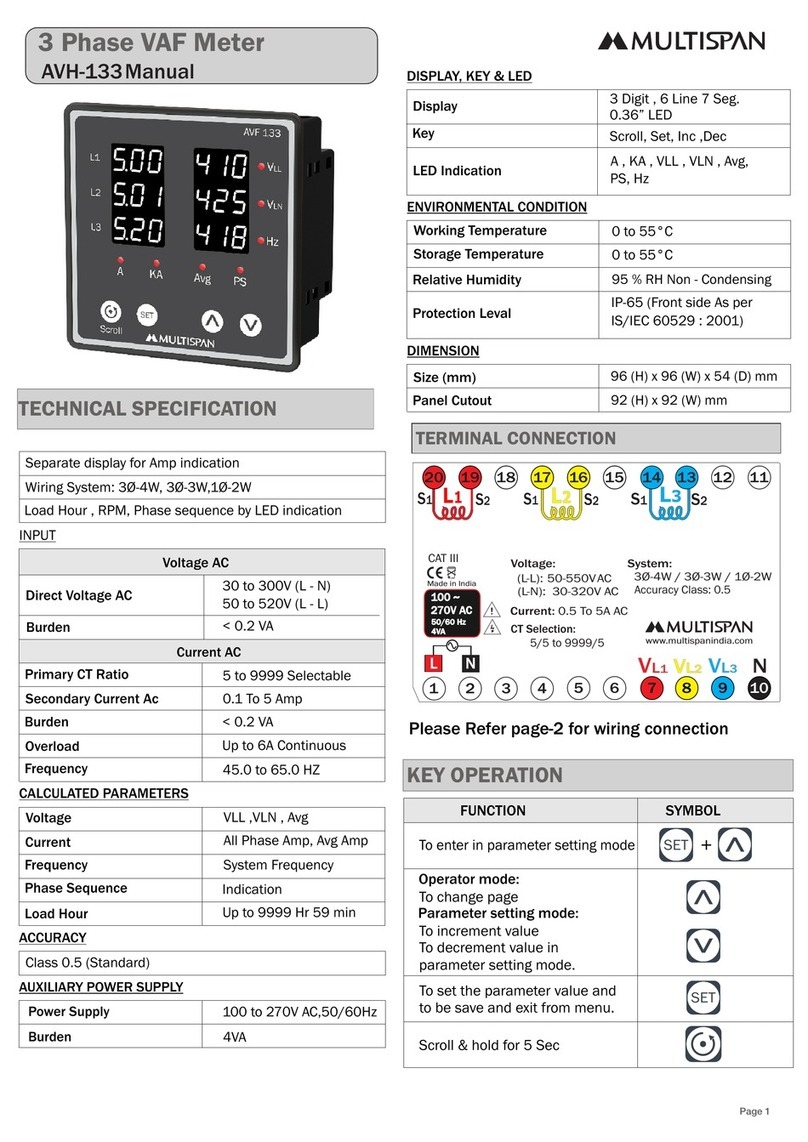

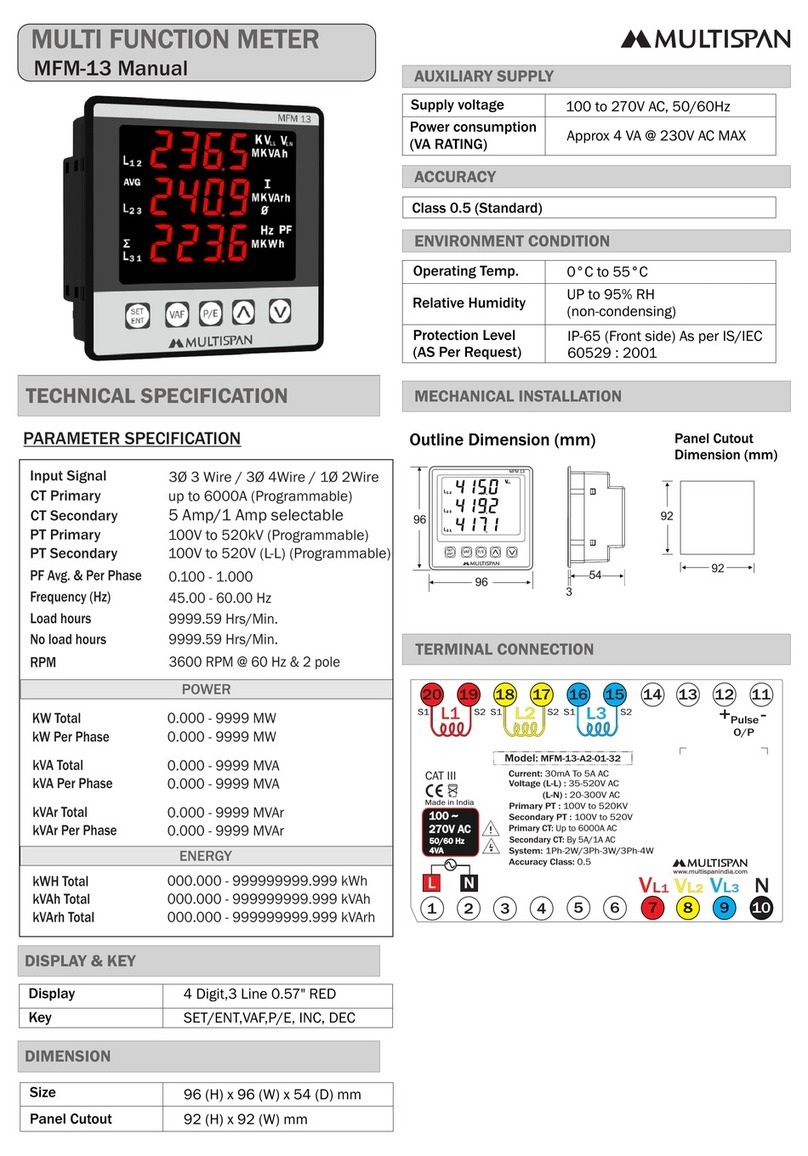

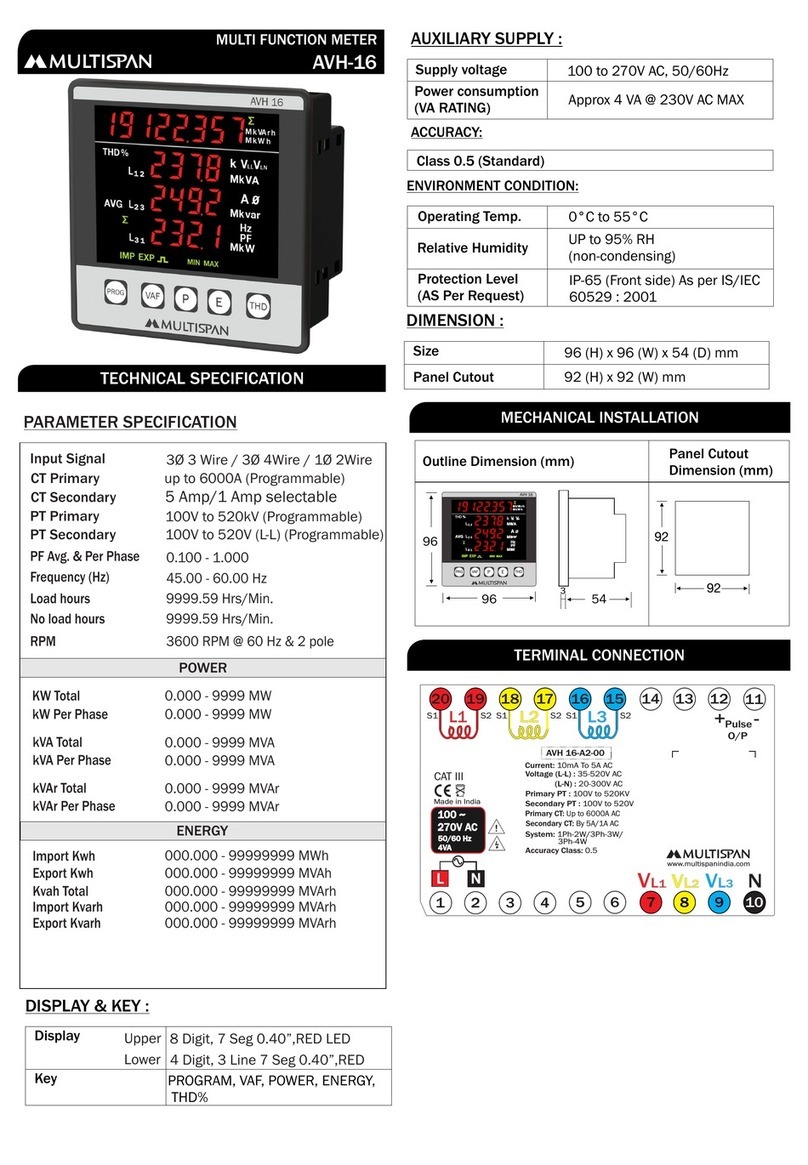

TERMINAL CONNECTIONOutline Dimension (mm)Panel Cutout Dimension (mm)96929296543To view VAF PagesTo view Power & Energy PagesTo scroll & hold pages Press for 3 secPress for 5 secKEY OPERATIONPRESS KEYFUNCTIONOPERATOR MODE

PARAMETER SETTING MODE

To Set Parameter ValueTo Increment parameter valueTo Decrement parameter valueTo Exit from parameter settingPARAMETERRANGE

Phase Neutral Voltage (V) LN0.000 - 9999 MW0.000 - 9999 MW000.000 - 99999999 MWH000.000 - 99999999 MVAh000.000 - 99999999 MVArh0.10 - 1.000.10 - 1.000.000 - 9999 MVA9999.59 Hrs/Min.0.000 - 9999 MVAr3000 RPM45 - 65 Hz9999.59 Hrs/Min.Line CURRENT ( ~A )Line Voltage (V)LL100 to 520kV (With PT) (With PT) 60 to 300kV (With CT) 0.5 to 6000A Active Power ( MW ) TotalActive Power per Phase(MW)Active Energy ( MWH ) Apparent Energy ( MVAh ) Reactive Energy ( MVArh) Power Factor ( PF ) AveragePower Factor per phase ( PF ) Apparent Power (MVA )Load hoursReactive Power ( MVAr )RPMFrequency ( Freq )No load hours

MFM 13LLSETENTVAFP/ELL 1) Voltage L-N 1) kW PER PHASE 5) kWh Total 4) kWh Total 6) kvah Total 5) kvah Total 6) kvarh Total7) kvarh Total 2) kVA PER PHASE 3) kvar PER PHASE 4) TOTAL kVA,kvar,kW 3) TOTAL kVA,kvar,kW 2) Voltage L-L3) CurrentLN4) System Frequency10) AVG V(L-L)-A-PF

LLLL 6) AVG V(L-L)-A-F 8) System PF5) AVG V(L-N)-A-F1) V(L-N)-A-F2) V(L-N)-A-PFLNLN 9) AVG V(L-N)-A-PF

7) PF L1L2L3

3 PHASE- 4 WIRE Note : In 3P-3W Page 2,3,4,6,8,10 will display Note : In 3P-3W Page 4,5,6,7 will display LNLNVAFP/E+

PAGE DESCRIPTION Press key VAF Long Press key VAF Pages : BASIC MODE PAGES PARAMETER SETTING Press key to change page VAFPress key to change page POWER & ENERGY Pages : 1Phase 2 wire Pages P/EEnter Password 10

////Network Selection Press key to save & exit from parameter setting CT Primary PT Primary PT SecondaryMode selectionCT Secondary(5 Amp to 6000 Amp selectable) (100V to 520kV selectable) (100V to 520V selectable) (Basic / Advance) (5 Amp/1 Amp selectable) PRGPRGPRGPRGPRGPRGPRGEnter Password 10100-270V AC (SMPS), 50/60 Hz, Approx 4VAPOWERENERGYSPECIFICATIONCOMMUNICATIONInput Signal AccuracyPower SupplyCT PrimaryPT PrimaryCT SecondaryPT Secondary3Ø 3 Wire / 3Ø 4Wire / 1Ø 2Wire Standard Class 0.5RS-485 MODBUS ( Optional)up to 6000A (Programmable)100V to 520kV (Programmable)1/5A (Programmable)100V to 520V (L-L) (Programmable)

KW Total kW Per PhasekWH TotalPower Factor Average (PF)Power Factor per phase (PF)kVA TotalkVAr TotalkVA Per PhasekVAr Per PhaseLoad hoursRPMFrequency (Hz)No load hours

0.000 - 9999 kW0.000 - 9999 kW000.000 - 999999999.999 kWh000.000 - 999999999.999 kVAh000.000 - 999999999.999 kVArh0.100 - 1.0000.100 - 1.0000.000 - 9999 kVA0.000 - 9999 kVAr0.000 - 9999 kVA0.000 - 9999 kVAr

45.00 - 60.00 Hz9999.59 Hrs/Min.9999.59 Hrs/Min.

3600 RPM @ 60 Hz & 2 pole

kVAh TotalkVArh Total

ENVIRONMENT CONDITION:Relative HumidityProtection Level(AS Per Request) Operating Temp.0°C to 55°CUP to 95% RH (non-condensing)IP-65 (Front side) As per IS/IEC60529 : 2001Class 0.5 (Standard)ACCURACY:AUXILIARY SUPPLY :Supply voltage12V - 60V DCTECHNICAL SPECIFICATIONSET/ENT,VAF,P/E, INC, DEC4 Digit,3 Line 0.57" REDDisplay Key DISPLAY & KEY : Size Panel Cutout96 (H) x 96 (W) x 54 (D) mm92 (H) x 92 (W) mmDIMENSION :POWERENERGYInput Signal PARAMETER SPECIFICATIONPT PrimaryCT SecondaryPT Secondary3Ø 3 Wire / 3Ø 4Wire / 1Ø 2WireCT Primaryup to 6000A (Programmable)100V to 520kV (Programmable)5 Amp/1 Amp selectable100V to 520V (L-L) (Programmable)

KW Total kW Per PhasekWH TotalPF Avg. & Per PhasekVA TotalkVAr TotalkVA Per PhasekVAr Per PhaseLoad hoursRPMFrequency (Hz)No load hours

0.000 - 9999 MW0.000 - 9999 MW000.000 - 999999999.999 kWh000.000 - 999999999.999 kVAh000.000 - 999999999.999 kVArh0.100 - 1.0000.000 - 9999 MVA0.000 - 9999 MVAr0.000 - 9999 MVA0.000 - 9999 MVAr

45.00 - 60.00 Hz9999.59 Hrs/Min.9999.59 Hrs/Min.

3600 RPM @ 60 Hz & 2 pole

kVAh TotalkVArh Total

Press Press For 5SecFor 5 SecOutline Dimension (mm)Panel Cutout Dimension (mm)92929696543

S1S1S1S2S2S2

L1

L2

L3

LN1234789105620191817141312111615

+-Pulse O/P

!

Made in India

100 270V AC

~ 50/60 Hz4VACAT III

VL1VL2VL3N

Current: 30mA To 5A AC Voltage (L-L) : 35-520V AC(L-N) : 20-300V ACAccuracy Class: 0.5System: 1Ph-2W/3Ph-3W/3Ph-4W Model: MFM-13-A2-01-32Primary PT : 100V to 520KVSecondary PT : 100V to 520V

Primary CT: Up to 6000A AC Secondary CT: By 5A/1A AC

www.multispanindia.com

Resolution

PT Ratio x CT Ratio<15<150<1500<15000<150000>150000Pulse/Kwh0.01Kwh0.1Kwh1Kwh10Kwh100Kwh1000Kwh

S1S1S1S2S2S2

L1

L2

L3

1234789105620191817141312111615

+-Pulse O/P

!

Made in India

CAT III

VL1VL2VL3N

Current: 30mA To 5A AC Voltage (L-L) : 35-600V AC(L-N) : 20-350V ACAccuracy Class: 0.5System: 1Ph-2W/3Ph-3W/3Ph-4W Primary PT : 100V to 520KVSecondary PT : 100V to 520V

Primary CT: Up to 6000A AC Secondary CT: By 5A/1A AC

www.multispanindia.com

-

+

12V 60VDC