1

Table of Contents

1. INTRODUCTION....................................................................................................................................2

2. TECHNICAL FEATURES..........................................................................................................................2

2.1 Functional equipment.................................................................................................................2

2.2 Design features ...........................................................................................................................2

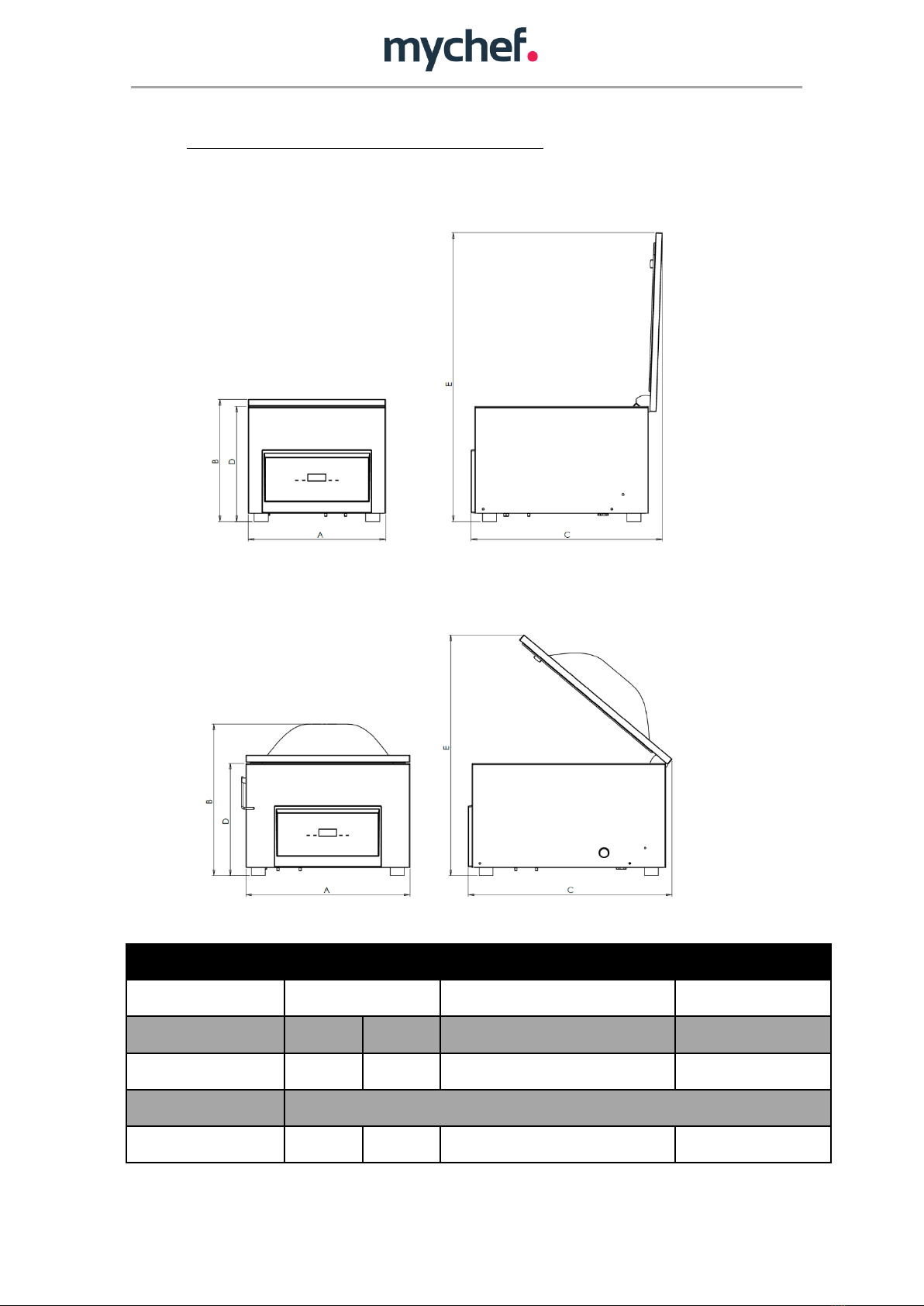

2.3 General measurements of goSensor countertop models...........................................................3

2.4 Vacuum chamber measurements and countertop model goSensor specifications ...................4

3. GENERAL STANDARDS FOR SAFETY AND ACCIDENT PREVENTION......................................................5

3.1 Personnel in charge of the use of the appliance.........................................................................5

3.2 Electrical hazard..........................................................................................................................5

3.3 Thermal hazard ...........................................................................................................................5

4. INSTALLATION......................................................................................................................................6

5. CONTROL PANEL ..................................................................................................................................6

6. CALIBRATION .......................................................................................................................................9

6.1 Automatic SCS Calibration ..........................................................................................................9

7. OPERATION........................................................................................................................................10

7.1 Connecting and turning on the appliance.................................................................................10

7.2 Operating modes ......................................................................................................................11

7.2.1 Manual mode: ..................................................................................................................11

7.2.2 Autoclean: ........................................................................................................................13

7.3 Packing ......................................................................................................................................13

8. ERRORS ..............................................................................................................................................15

9. MAINTENANCE ..................................................................................................................................16

9.1 Cleaning ....................................................................................................................................16

9.2 Vacuum pump oil ......................................................................................................................16

9.3 Sealing bar.................................................................................................................................16

9.4 Water-tight seal on the lid ........................................................................................................16

10. MAINTENANCE SCHEDULE ............................................................................................................17

10.1 Check the oil level .....................................................................................................................17

10.2 Change the pump oil.................................................................................................................18

10.2.1 Countertop goSensor .......................................................................................................18

10.3 Other maintenance operations.................................................................................................22

10.4 Owner liability...........................................................................................................................22

11. SPECIFICATIONS.............................................................................................................................23

11.1 General electrical diagram Countertop goSensor SMALL, MEDIUM AND LARGE.....................24

11.2 Pneumatic diagram ...................................................................................................................25