Table 1. Control board indicators, displays and buttons

5.2.Self Calibration System (SCS)

The iSensor floor standing vacuum packers have a fully automatic calibration system, Self

Calibration System (SCS), patented by MyChef. As a result of this automatic recalibration

algorithm of the vacuum percentage, we have the following advantages:

•Calibration without user intervention

The appliance automatically detects optimal calibration conditions and, completely

autonomously, can recalibrate itself according to the following physical changes:

-Automatic adaptation to temperature variations.

-Automatic adaptation to climate variations.

-Automatic adaptation to altitude variations.

-Automatic adaptation to variation in oil properties.

The appliance is able to detect increases and decreases in differential atmospheric

pressure, recalibrating itself as needed.

•Increased precision in measuring the vacuum

By constantly calibrating itself automatically, the values used to calculate the vacuum

percentage are dynamically updated. Therefore, the vacuum percentage that the

user selects has a smaller error margin than if it were to not dynamically calibrated.

The SCS calibration system determines when it is necessary to perform a calibration and

does so automatically without the user intervention. However, the user can force a

calibration at any time simply by making a packaging with 100% vacuum.

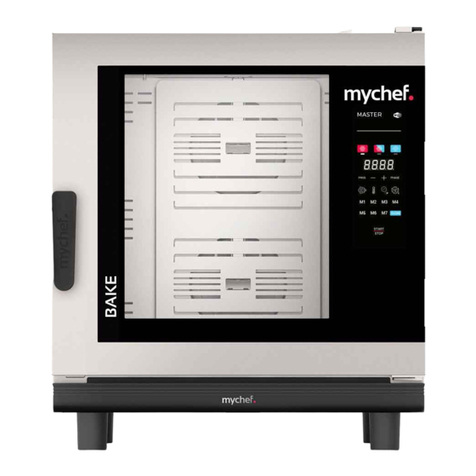

5.3.Connecting and turning on the appliance

When the appliance is connected to the electricity grid, a start-up process takes place where

all internal values are initialized, and safety and control checks are carried out to ensure

optimum control of the vacuum packing. This process will be indicated on the screen by the

simultaneous flashing of all segments for a number of seconds.

While the segments are flashing, you can check the technical control parameters by

pressing the centre button. These parameters may be relevant for the maintenance of the

appliance. Two parameters will be displayed:

-Vacuum pump operating hours.

-Number of vacuum cycles performed.

The first value displayed is the operating hours of the vacuum pump. This will be identified

by the "Vacuum" icon, which will light up in the right-hand block of the screen. The digits of

the number will be shown on the central display cyclically by marking the end of the digits