3

hyperion X5 2D/3D

EN 2D/3D OPT E.L. CALIBRATION MANUAL

CONTENTS

1. REQUIRED INSTRUMENTS .................................................................................................................. 5

2. PRELIMINARY OPERATIONSPRELIMINARY OPERATIONS .............................................................. 7

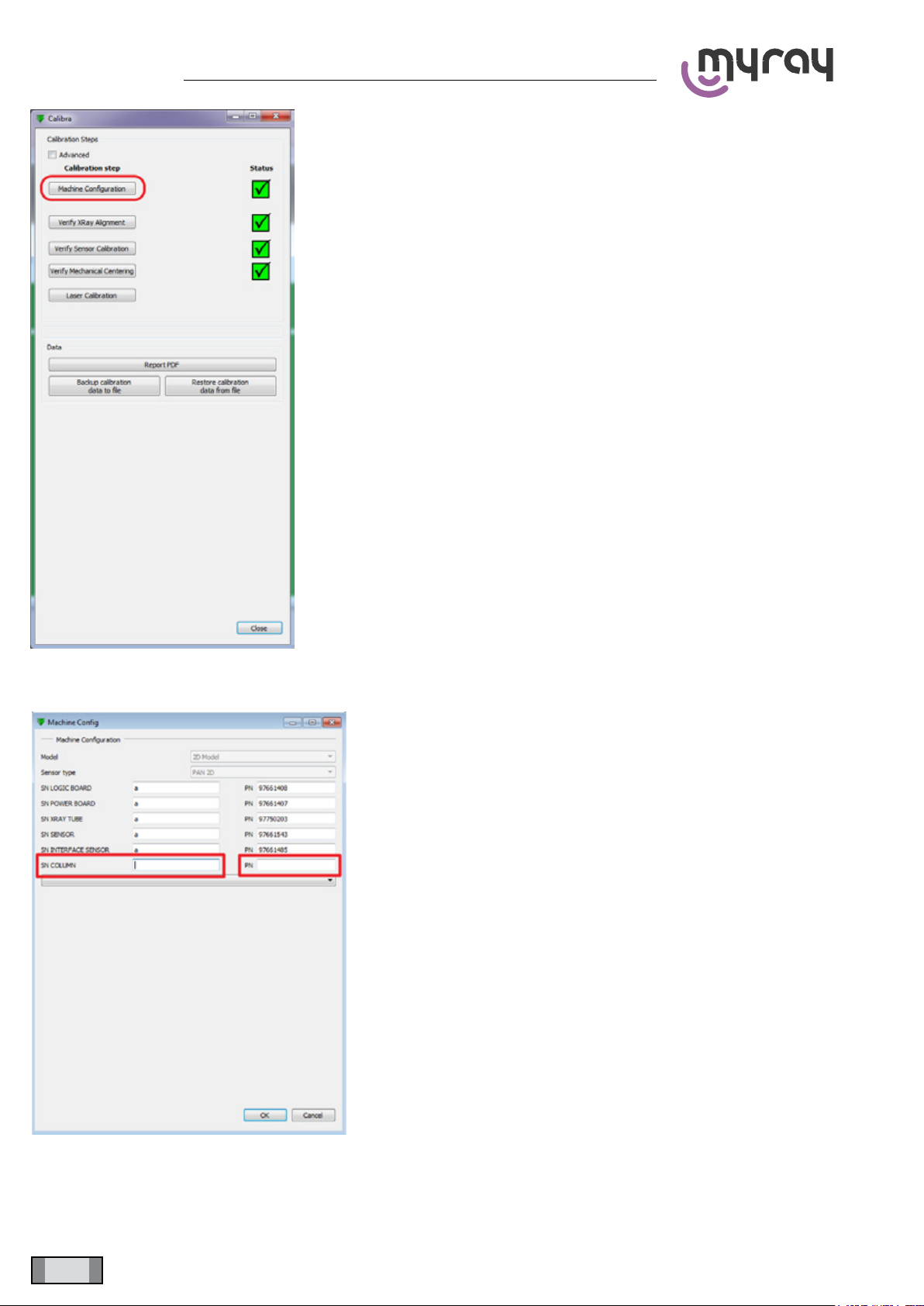

3. 2D CALIBRATION................................................................................................................................... 9

3.1 X-RAY ALIGNMENT CHECK ............................................................................................................ 9

3.2 SENSOR CALIBRATION CHECK................................................................................................... 14

3.3 VERIFYING THE MECHANICAL CENTERING ............................................................................. 15

3.4 LASER CALIBRATION ................................................................................................................... 17

3.5 CALIBRATION DATA BACKUP ...................................................................................................... 19

4. 3D CALIBRATION................................................................................................................................. 20

4.1 RAY BEAM CALIBRATION ............................................................................................................. 20

4.2 DAILY CHECK AND BLANK ACQUISITION ................................................................................... 26

4.3 TIN SCAN ....................................................................................................................................... 28

4.4 QA PHANTOM ACQUISITION (OPTIONAL) .................................................................................. 31

4.5 CALIBRATION DATA BACKUP....................................................................................................... 33