1

Important Information

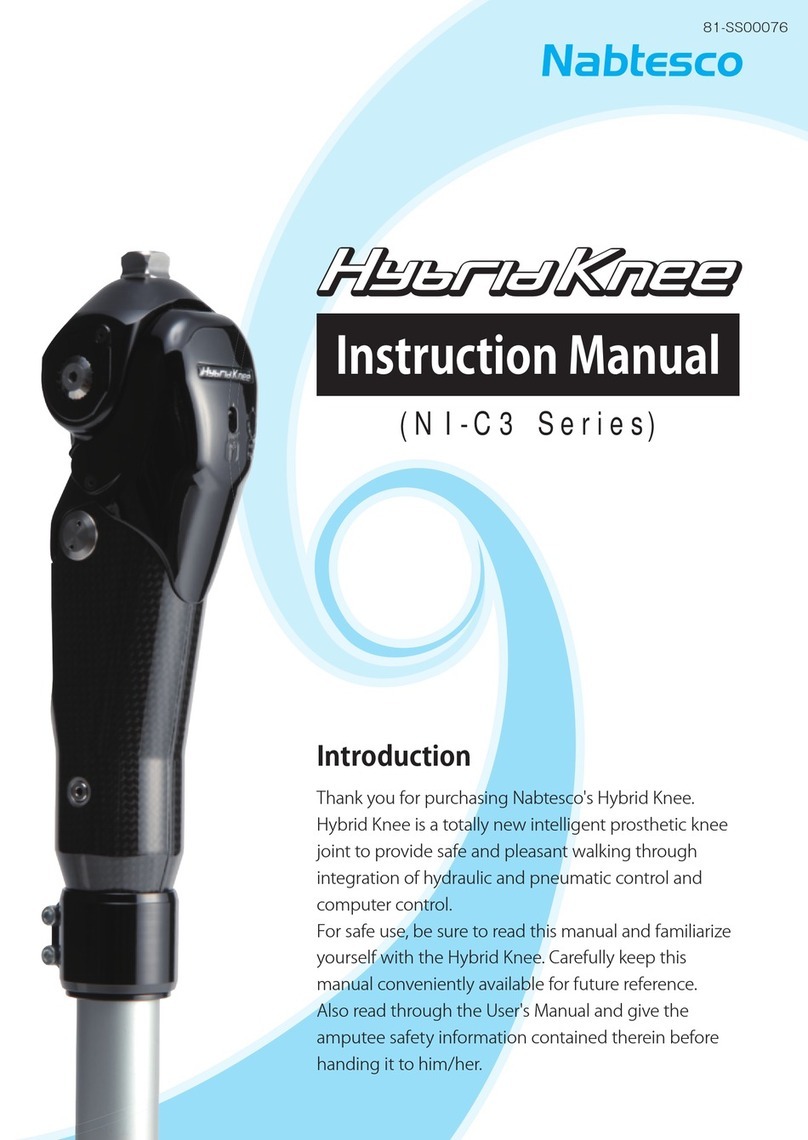

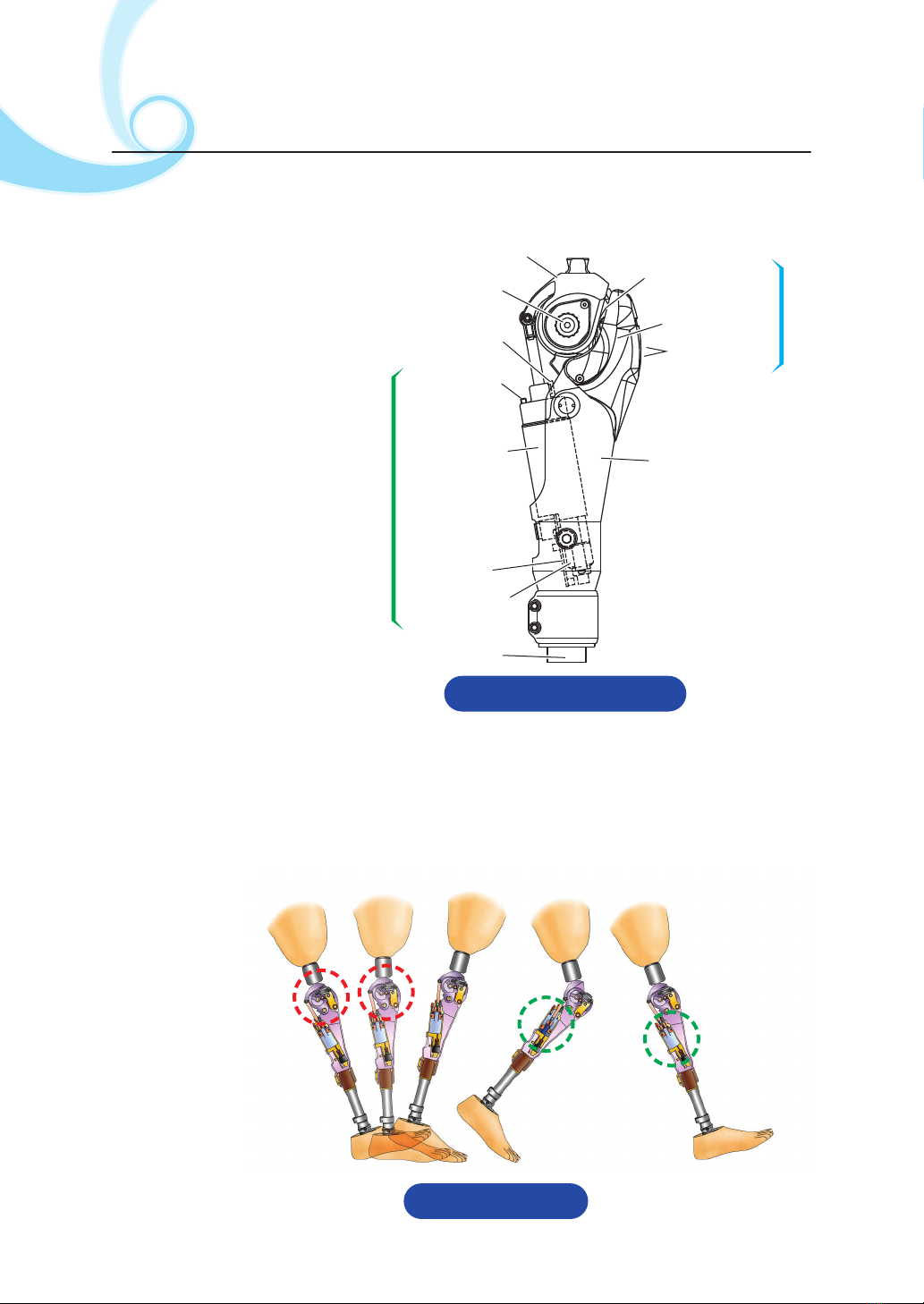

Intended purpose of Hybrid Knee

Hybrid Knee was designed and is manufactured for use as a prosthetic knee joint by above-

knee amputated, knee disarticulated, and hip disarticulated patients. Do not use Hybrid

Knee for any other purposes. For hip prostheses, it is recommended to use a torsion adapter

to prevent significant torsion from being applied to Hybrid Knee. This device is intended for

single patient multiple use.

For the specifications for Hybrid Knee, see 8. Product Overview.

WARNING

■Do not use Hybrid Knee outside of the specification range. Do not modify the

main body or parts.

Doing so can cause injury or damage Hybrid Knee.

Cautions for handling Hybrid Knee safely

Nabtesco Corporation (hereinafter referred to as "Nabtesco") cannot foresee all potential re-

sidual risks of Hybrid Knee and risks resulting from human errors and the usage environment.

Although there are many instructions and prohibitions for handling Hybrid Knee (assem-

bling, adjusting, and maintaining the prosthesis), all these matters cannot be described in

this document or on the warning labels on the body of Hybrid Knee.

Therefore, when handling Hybrid Knee, it is necessary not only to observe the precautions stat-

ed in this document, but also to take the safety measures necessary for a prosthesis knee joint.

Particularly important matters concerning the safe handling of Hybrid Knee are described

below. These matters apply to the persons who assemble and adjust Hybrid Knee.

If you have a serious incident related to Hybrid Knee, please report it to the manufacturer

(contact information on the back cover) and the competent authority in your country.

Read this document thoroughly

Before handling Hybrid Knee, thoroughly read this document, and sufficiently understand

the contents. Strictly observe the safety precautions stated in the document.

Qualification of assemblers and adjusters

Anyone assembling or adjusting Hybrid Knee must have attended Hybrid Knee license semi-

nars and be a licensed prosthetist. Outsourcing to anyone else is strictly prohibited.