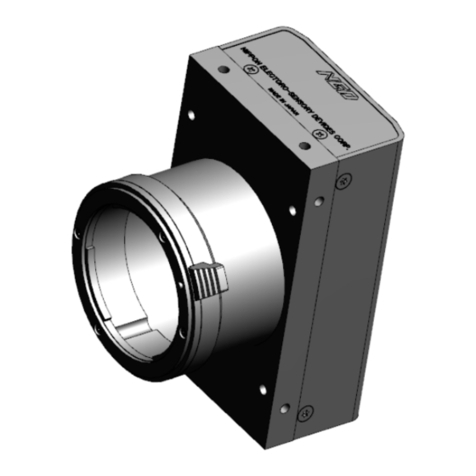

NED CoaXpress XCM80160CXP User manual

User’s Manual

Line Scan Camera

Type: XCM80160CXP/60160CXP/40160CXP

NIPPON ELECTRO-SENSORY DEVICES CORPORATION

2

NED

XCM80160CXP_60160CXP_40160CXP UME-0022-02

For Customers in U.S.A.

This equipment has been tested and found to comply with the limits for a Class A

digital device, in accordance with Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation

of this equipment in a residential area is likely to cause harmful interference, in which

case the user will be required to correct the interference at his or her own expense.

For Customers in the EU

This equipment has been tested and found to comply with the essential requirements

of the EMC Directive 2004/108/EC, based on the following specifications applied:

EU Harmonised Standards

EN55011: 2009+A1: 2010 Group1 Class A

EN61000-6-2: 2005

*Group 1 contains all ISM (Industrial, Scientific and medical) equipment in which there

is intentionally generated and/or used conductively coupled radio-frequency energy

which is necessary for the internal functioning of the Equipment itself.

*Class A equipment is equipment suitable for use in all establishments other than

domestic and those directly connected to a low voltage power supply network which

supplies buildings used for domestic purposes.

Directive on Waste Electrical and Electronic Equipment (WEEE)

Please return all End of Life NED products to the distributor from whom the product

was purchased for adequate recycling and / or disposal. All costs of returning the

Product to NED are borne by the shipper.

NED

UME-0022-02XCM80160CXP_60160CXP_40160CXP

3

Introduction

Thank you for purchasing NED’s Line Scan Camera. We look forward to your

continued custom in the future.

For safety use

For your protection, please read these safety instructions completely before

operating the product and keep this manual for future reference.

The following symbols appear next to important information regarding safe product

handling.

Warning

If the product is not handled properly, this may result

in serious injury or possible death.

Caution

If the product is not handled properly, this may result

in physical injury or cause property damage.

Safety precaution

Warning

Never disassemble or modify this product, unless otherwise specified to do so in this

manual.

When hands are wet, avoid handling this product and do not touch any of the

connection cable pins or other metallic components.

Do not operate this product in an environment that is exposed to rain or other severe

external elements, hazardous gases or chemicals.

If the product is not to be used for an extended period of time, as a safety precaution,

always unplug the connection cable from the camera unit.

If the product installation or inspection must be executed in an overhead location,

please take the necessary measures to prevent the camera unit and its components

from accidentally falling to the ground.

If smoke, an abnormal odor or strange noise is emitted from the camera unit, first

turn OFF power, then unplug the cable from the camera unit.

This product is not intended for use in a system configuration built for critical

applications.

4

NED

XCM80160CXP_60160CXP_40160CXP UME-0022-02

Instructions before use

Only operate this product within the recommended environmental temperature

range.

Use only the specified power source and voltage rating.

Do not drop this product. Avoid exposure to strong impact and vibrations.

Install the camera unit in a well-ventilated environment, in order to prevent the

camera from overheating.

If the camera must be installed in an environment containing dust or other particles,

take required measures to protect the camera unit from dust adhesion.

Do not unplug the cable while power is being supplied to the camera unit. To

prevent product damage, always shut down the power supply before unplugging the

power cable.

When the surface of the camera window becomes dirty due to dust or grime, black

smudges appear in the displayed image. Use an air blower to remove the dust

particles. Dip a cotton swab into ethanol alcohol and clean the camera window. Be

careful not to scratch the glass.

Use of non-infrared lighting such as a daylight fluorescent lamp is recommended. If

halogen lighting is employed, always install an infrared filter into your system

configuration.

Please note that exposure to long wavelength light outside of the sensors visible

optical range can affect the image.

Sensitivity may fluctuate depending on the spectral response level of the light

source. In cases like this, changing the light source to one with a different spectral

response level may reduce this problem.

For stabilized image capturing, turn ON the power supply and execute aging for ten

to twenty minutes before actually using the camera unit.

Do not share the power supply with motor units or other devices that generate noise

interference.

Do not disconnect the camera while rewriting the embedded memory.

When you change the exposure mode that is set at the NED factory, input control

signal (Trigger packet) from the capture board.

NED

UME-0022-02XCM80160CXP_60160CXP_40160CXP

5

Product Warranty

Warranty Period

The product warranty period, as a general rule, is two years from purchase;

however for detailed conditions please contact the sales representative for your

region/country.

However, in some cases due to the usage environment, usage conditions and/or

frequency of use, this warranty period may not be applicable.

Warranty Scope

Product repair will be performed on a Return To Manufacturer basis. On-site

maintenance will incur additional charges.

If defects in material or workmanship occur during the warranty period, the faulty

part will be replaced or repaired by us free of charge. Return shipping charges must

be paid by the sender. However, the following cases fall outside of the scope of this

warranty:

Exclusions from Warranty Coverage

We will under no circumstances assume responsibility for the following cases:

damage caused by fire, earthquake, other acts of a third party, other accidents,

negligent or intentional misuse by the user, or other usage under extraordinary

circumstances.

Damages (e.g. loss of business profits, business interruption, etc.) resulting from

use or non-use.

Damages caused by use other than as described in this document.

Damages resulting from malfunction due to a connected device.

Damages resulting from repairs or modifications performed by the customer.

Fault Diagnosis

As a general rule, in the first instance fault diagnosis should take the form of a

telephone call or an email to enable us to assess the circumstances of the

malfunction.

However, depending on the customer’s requests, we, or our agent, may require an

additional fee for this service.

6

NED

XCM80160CXP_60160CXP_40160CXP UME-0022-02

Exclusion of Liability for Compensation for Missed Opportunities

Regardless of whether within the warranty period or not, our warranty does not

cover compensation for missed opportunities for our customers, or our customers’

customers, caused by a fault of our products, nor for damage to products other than

our own, or related business.

Note about Product Usage

This product has been designed and manufactured as a general-purpose product

for general industry. In applications expected to be life-critical or safety-critical, the

installer or user is requested to install double or triple failsafe systems.

Repair Service Outline

The cost of dispatching engineers etc. for repair service is not included in the price

of purchased and supplied goods. On request, arrangements can be made

separately.

Scope of Repair Service

The above assumes business dealings and usage to take place in the customer’s

region / country. In cases of business dealings and/or usage outside the customer’s

region/country, separate consultation is required.

NED

UME-0022-02XCM80160CXP_60160CXP_40160CXP

7

Table of Contents

1 Product Outline ....................................................................10

1.1 Features...........................................................................................................10

1.2 Applications ....................................................................................................10

1.3 Image Sensor ..................................................................................................12

1.4 Performance Specifications...........................................................................12

2 Camera Setting and Optical Interface ................................15

2.1 Setting Camera................................................................................................15

2.2 Fixing Camera .................................................................................................15

2.3 Optical Interface..............................................................................................18

3 Hardware...............................................................................19

3.1 Camera Connection........................................................................................19

3.2 Input / Output Connectors and Indicator ......................................................19

3.3 Power Supply ..................................................................................................20

3.4 LED Indicator Status.......................................................................................21

4 Camera Startup ....................................................................22

4.1 Camera Startup Procedure.............................................................................22

5 Camera Control ....................................................................23

5.1 Flow of Camera Control..................................................................................23

5.1.1 GenICam overview ...................................................................................23

5.1.2 Camera Control registers ........................................................................23

5.1.3 Memory Setup Values (Factory Settings)...............................................25

5.2 Programmable Exposure Time・Exposure-Readout Time calculation

procedure ..............................................................................................................26

5.3 Details on register system .............................................................................26

5.3.1 Setting Analog Gain.................................................................................28

5.3.2 Setting Digital Gain ..................................................................................28

5.3.3 Setting Digital Offset................................................................................29

5.3.4 Setting Exposure Mode............................................................................29

5.3.5 Setting Exposure Time.............................................................................30

5.3.6 Setting Output Signals (Setting Data Format)........................................30

5.3.7 Memory Initializing (Initializing Camera Settings).................................31

5.3.8 Memory Load (Reads out the camera settings from the flash memory )

............................................................................................................................31

8

NED

XCM80160CXP_60160CXP_40160CXP UME-0022-02

5.3.9 Memory Save ............................................................................................31

5.3.10 Generating Test Pattern.........................................................................31

5.3.11 Saving Pixel Correction Data.................................................................31

5.3.12 Setting Pixel Correction.........................................................................32

5.3.13 Setting Exposure Time - Readout Time................................................32

5.3.14 Setting Pixel Readout Direction............................................................33

5.3.15 Dynamic Range Control (Multi-Slope) Settings...................................33

5.4 Digital Processing flow in FPGA....................................................................34

5.5 Startup .............................................................................................................34

5.6 Saving and Loading Camera Settings...........................................................35

5.7 Video Output Format ......................................................................................36

5.8 XML file............................................................................................................36

5.9 Exposure Mode and Timing Chart.................................................................37

5.9.1 Free Run Exposure Mode ........................................................................37

5.9.2 External Trigger Exposure Mode (Trigger Edge)...................................38

5.9.3 External Trigger Exposure Mode (Trigger Level)...................................39

5.10 Setting Offset ................................................................................................40

5.11 Setting Gain...................................................................................................41

5.12 Pixel Correction.............................................................................................43

5.13 Test Pattern ...................................................................................................44

6 Confirming Camera Settings...............................................46

6.1 Before Power-on .............................................................................................46

6.2 After Power-on ................................................................................................47

6.3 During Operation.............................................................................................48

7Dynamic Range Control (Multi-Slope Mode)...................49

7.1 MultiSlope Mode Default Setting Operation .................................................49

7.2 Standard Mode................................................................................................51

7.3 1 When bending the response curve.............................................................52

7.4 Bending the line three times..........................................................................54

8 Sensor Handling Instructions.............................................56

8.1 Electrostatic Discharge and the Sensor .......................................................56

8.2 Protecting Against Dust, Oil and Scratches.................................................56

8.3 Cleaning the Sensor Window.........................................................................56

9 Others....................................................................................57

9.1 Notice...............................................................................................................57

10

NED

XCM80160CXP_60160CXP_40160CXP UME-0022-02

1 Product Outline

1.1 Features

CoaXPress interface

CXP-2(2.5 Gbps). cable length up to about 100 m

High-integrity data

Real-time action

Up Link trigger semantics

Device Discovery

GENiCAM correspondence

1.2 Applications

Inspection of Transparent panels and PCBs

Inspection of high speed moving objects

Flat panel display inspection

Inspection of glass and sheet-like objects

Printed circuit board inspection

Outdoor surveillance

Wide dynamic range prevents saturation caused by direct rays and specular

reflection rays.

NED

UME-0022-02XCM80160CXP_60160CXP_40160CXP

11

An example of Visual Inspection of PCBs is shown below.

Figure 1-2-1 Visual Inspection of PCBs

Applicable Work

COB, BGA and MCM printed circuit boards

Performance

1. Maximum board size: 100 mm × 200 mm

2. Resolution: 10 μm

3. Inspection time: less than 30 seconds

Unit Configuration

1. Camera: Line scan camera (8192 / 6144 pixels)

2. Controller: Dedicated software for PC system

3. Size: L930 x D500 x H500 (mm)

Applicable Fields

Inspection of patterns on film PCBs

Line scan camera

12

NED

XCM80160CXP_60160CXP_40160CXP UME-0022-02

1.3 Image Sensor

The camera uses a CMOS sensor with a maximum data rate of 160MHz to acquire

high responsivity and superior quality images.

The pixel size is 7μmx7μm.

XCM80160CXP outputs 8192 pixel data, XCM60160CXP outputs 6144 pixel data,

XCM40160CXP outputs 4096 pixel data through a Single CXP-2 CoaXPress

interface.

1.4 Performance Specifications

The Performance Specifications are shown below. Unless otherwise specified, the

data shown is when the camera is operating at the maximum scan rate.

Table 1-4-1 Performance Specifications

Items

Specifications

XCM80160CXP

XCM60160CXP

XCM40160CXP

Number of Pixels

8192

6144

4096

Pixel Size HxV (μm)

7x7

Sensor Length (mm)

57.344

43.008

28.672

Spectral Responsivity (nm)

400~1000 ※Peak 625

Data Rate (MHz)

160(40×4)

Maximum Scan Rate

(μs)/[kHz]

53.6/[18.65]

40.2/[24.88]

29.8/[33.58]

Saturation Exposure (lx・s)

(typically)

0.071[Minimum Gain, Pixel Correction Initial Value, Daylight

Fluorescent Light]

Responsivity (typically)

[Minimum Gain, Pixel Correction

Initial Value, Daylight

Fluorescent Light]

Visible Area (400~700nm)

70(V/[lx・s])

Analog 5V Conversion Sensitivity

40.7(V/[μJ/cm2])

Gain Adjustable Range

*Analog Amplifier +Digital

Analog Amplifier: x1~x11.2(21STEP)

Digital: x1~x2(512STEP)

Offset Adjustable Range

*Digital

Digital: -15~15DN(31STEP)8bit

-60~60DN(31STEP)10bit

FPN

(Fixed Pattern Noise)

Typically 5DN(without correction, at minimum gain)

2DN(with correction, at minimum gain)

NED

UME-0022-02XCM80160CXP_60160CXP_40160CXP

13

PRNU(Photo Response Non

Uniformity)

Typically 20DN(without correction, at minimum gain)

4DN (with correction, at minimum gain)

Random Noise

Typically 20DN (peak value at minimum gain)

Video output

CoaXPress

Connectors

Data/Controller

Canare: BCJ-FPC(75Ω)

Power Supply

Hirose: HR10A(6Pin)

Lens Mount

M72x0. 75 Screw

Nikon F Mount

Operating Temperature (˚C)

No Condensation

0 to 50

Power Supply Voltage (V)

DC12~15[±5%]

Consumption Current (mA)

(typically)

600

Size W x H x D (mm)

80x120x77

80x120x91

(Nikon F Mount)

Mass (g) (Camera only)

Approx. 600

Approx. 730

Additional Functions

1. Shading Correction

2. Gain/Offset Control, 8 or 10 bit Video Output Adjustable

3. Test Pattern Selection

4. Programmable Exposure Control

5. Scan Direction Switching

*1) DN : Digital Number (10bit : 0 -1023)

*2) Measurements were made at room temperature.

Interface part specifications

Bit Rate

2.5Gbps (CXP-2)

Discovery Rate

1.25Gbps (CXP-1)

(at the time of Device discovery)

Number of Links

1(cable)

power line carrier system

(PoCXP)

unsupported

(Separate power supply required.)

Pixel Format

black and white 8bit ・10bit (Mono8 ,Mono10)

Image Type

Rectangular

External trigger

(Low Speed Link Trigger)

frame grabber(Host)→ camera(Device)

jitter ±8ns

14

NED

XCM80160CXP_60160CXP_40160CXP UME-0022-02

The spectral Responsivity is shown below.

(Ta=25℃)

Figure 1-4-1 Spectral Responsivity

20

40

60

80

100

0

400 500 600 700 800 900 1000

Wavelength (nm)

Relative Responsivity (%)

NED

UME-0022-02XCM80160CXP_60160CXP_40160CXP

15

2 Camera Setting and Optical Interface

2.1 Setting Camera

Use the M4 screw holes or the screw hole for a tripod to set the camera.

An optional mounting base (sold separately) is available.

2.2 Fixing Camera

Use the M4 screw holes (4 places at the front, 8 places at the side) to fix the

camera.

Or use the 1/4"-20UNC screw hole for a tripod (1 place at the side).

If using the front panel M4 mounting holes, the screw length for fixing the camera

should be less than 8mm at the front, and less than 6mm at the side.

No X-, Y-axis orientation and tilt adjustment mechanism is available. Please provide

an adjustment mechanism yourself as necessary.

16

NED

XCM80160CXP_60160CXP_40160CXP UME-0022-02

The dimensions for cameras are shown below.

NIPPON ELECTRO-SENSORY DEVICES

CORP.

MADE IN JAPAN

NIPPON ELECTRO-SENSORY DEVICES

CORP.

MADE IN JAPAN

DC12-15V

DIGITA

L

LINESCAN

CAMERA

C L IS B e e

80

Unit: mm

*31.8

1st Pixel

M72 x 0.75 Depth 10

(Flange back)

10

5

(77 )

Indicator Power Supply Connecor

(HIROSE HR10A 6P)

BNC(Canare:BCJ-FPC)

65

4-M4 Depth 6 (Both Sides)

4-M4 Depth 8 (Front Surface)

4-M4 Depth 6

(Top,Bottom)

65

65

1/4"-20UNC

20

7.5

S

80

Ø

90

60 5

70 25

120

5

72x0.75 Screw Mount

Figure 2-2-1 Dimensions (M72x0.75 Screw Mount)

NED

UME-0022-02XCM80160CXP_60160CXP_40160CXP

17

DC12-15V

DIGITAL

LINESCAN

CAMERA

CLISBee S

80

65

34.7

( 91 )

46.5 (Flange back)

5

10

1/4"-20UNC

60

15

90

4-M4 Depth 6 (Both Sides)

NIPPON ELECTRO-SENSORY DEVICES

CORP.

MADE IN

JAPAN

NIPPON ELECTRO-SENSORY DEVICES

CORP.

MADE IN

JAPAN

65

Unit : mm

Indicator BNC(Canare BCJ-FPC)

Power Supply Connector

(HIROSE HR10A 6P)

120

70 25

55

Nikon F Mount

1st Pixel

4-M4Depth 6

(Front Surface)

4-M4 Depth 6

(Top, Bottom)

Figure 2-2-2 Dimensions (Nikon F Mount)

18

NED

XCM80160CXP_60160CXP_40160CXP UME-0022-02

2.3 Optical Interface

The lens mount depends on the type of camera.

For XCM80160CXP, M72×0.75 screw mount is used. For XCM60160CXP,

XCM40160CXP, Nikon F mount is used.

The amount and wavelengths of light required to capture useful images depend on

the intended use. Factors include the property, speed, the object’s spectral

characteristics, exposure time, the light source characteristics, the specifications of

the acquisition system and so on.

The exposure amount (exposure time x light amount) is the most important factor in

getting desirable images. Please determine the exposure amount after studying what

is most important to your system.

Keep these guidelines in mind when setting up your light source:

LED light sources are relatively inexpensive, provide a uniform field and longer

life span compared to other light sources. However, they also require a camera

with excellent sensitivity.

Halogen light sources generally provide very little blue relative to infrared light

(IR).

Fiber-optic light distribution systems generally transmit very little blue light

relative to IR.

Metal halide light sources are very bright but have a shorter life span compared

to other light sources.

Generally speaking, the brighter light sources, the shorter life span.

CMOS image sensors are sensitive to infrared (IR). We recommend using daylight

color fluorescent lamps that have low IR emissions. If you use a halogen light source,

to prevent infrared from distorting the images use an IR cutoff filter that does not

transmit IR wavelengths.

NED

UME-0022-02XCM80160CXP_60160CXP_40160CXP

19

3 Hardware

3.1 Camera Connection

PC

Line scan camera

<Single:connection>

object

LED incident lighting

CXP cable

frame Grabber

board

<Single X 2:connection>

PC

frame Grabber

board

CXP cable

Line scan camera

LED incident lighting

object

Depending on the frame grabber board, it is possible to connect up to four cameras

at the time of [writing].

<Note : Choosing a coaxial cable>

Please use a 75Ωcoaxial cable with a BNC connector according to the CoaxPress

standard. The maximum cable length is not prescribed by the standard. The maximum

cable length to be able to transfer data depends on the coaxial cable and BNC

connector. We have been able to verify operation over 100m using the below

combination of coaxial cable and BNC connector:

Coaxial cable: L-5CFB (CANARE)

BNC connector: BCP-B5F (CANARE)

3.2 Input / Output Connectors and Indicator

The layout of input /output connecters and the indicator lamp are as follows.

DC12-15V

Indicator Power Supply Connector

DIGITAL

LINESCAN

CAMERA

CLISBee S

(HIROSE HR10G 6PB)

BNC

(Canare BCJ-FPC)

Figure 3-2-1 Input/output Connectors and Indicator

20

NED

XCM80160CXP_60160CXP_40160CXP UME-0022-02

The pin assignment of the power supply connector is shown below.

1

2

34

5

6

Figure 3-2-2 Power Supply Connector (HIROSE : HR10G -7R- 6PB)

Round shape push-pull lock type

Table 3-2-1 Pin Assignment of Power Supply Connector

No

Name

1

12-15V

2

12-15V

3

12-15V

4

GND

5

GND

6

GND

3.3 Power Supply

The camera requires a single power supply (DC+12 to +15V).

When selecting a power source, choose one with the capacity to allow for inrush

current. (15W or more recommended)

Insert the cable plug securely until it locks into position. This is to prevent the

connector from coming loose during power transmission.

Compatible Cable (Compatible plug): DGPSA-10 (HIROSE: HR10A-7P-6S)

Power supply voltage: DC+12-+15V (+/-5%)

Consumption Current (rated): DC+12V: 600mA

The LED lamp illuminates when +12V to +15V power is being supplied to the

camera.

If the lamp fails to illuminate even after power is supplied, turn OFF power

immediately. Inspect wiring. Check the voltage and capacity of the supplied power

source.

This manual suits for next models

2

Table of contents

Other NED Digital Camera manuals

NED

NED SUi7440 User manual

NED

NED XCM2080SAT4 User manual

NED

NED XCM16K80SAT8 User manual

NED

NED XCM6040SAT2 User manual

NED

NED SUi7450T2 User manual

NED

NED NUCLi7370AT6 User manual

NED

NED SU2025GIG User manual

NED

NED RMSL8K39CL User manual

NED

NED RMSL6K52CL User manual

NED

NED Camera Link XCM8040SAT4 User manual