NCF

9

EN

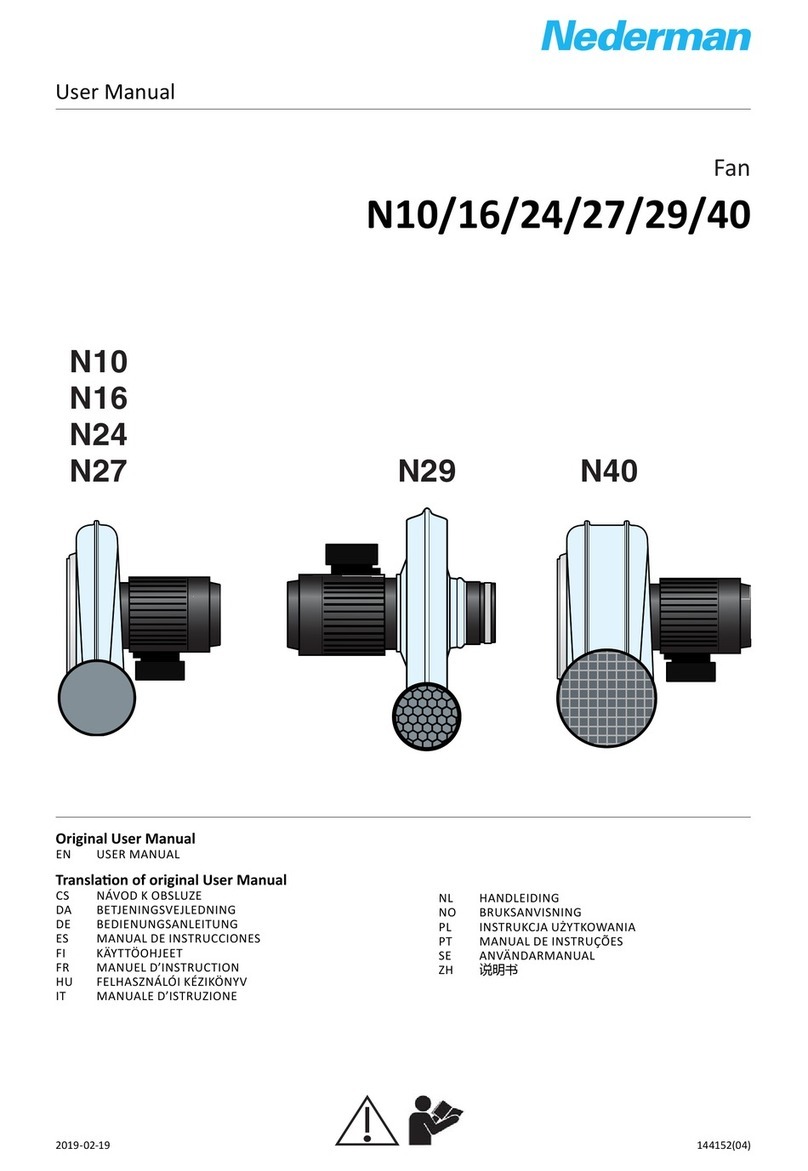

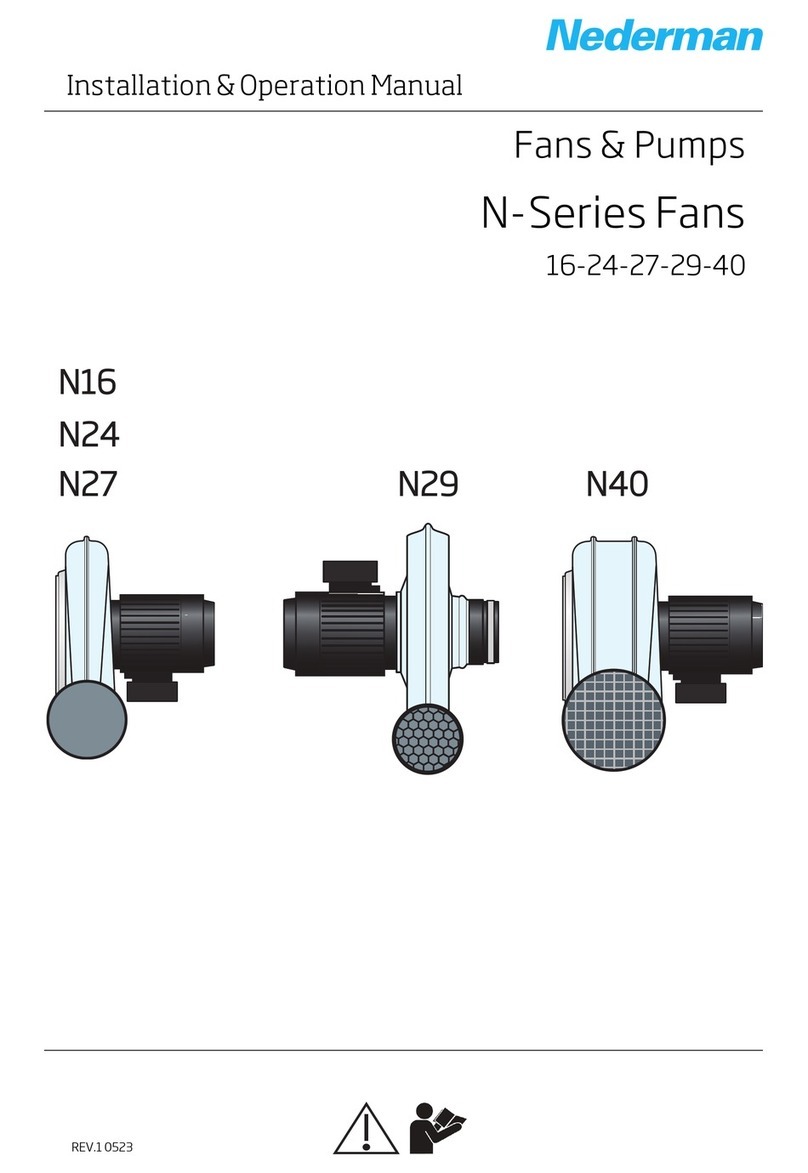

Table of contents

English

Instrucon manual

1 Preface ..............................................................................................................................................................................10

2 Safety .................................................................................................................................................................................10

2.1 General ..............................................................................................................................................................10

2.2 Mechanical characteriscs risks ..........................................................................................................11

2.3 Environmental risks ....................................................................................................................................11

2.4 Vibraon risks ................................................................................................................................................12

2.5 Operang speed risks................................................................................................................................13

2.6 Noise emission risks ...................................................................................................................................14

3 Descripon .....................................................................................................................................................................14

3.1 Intended use ..................................................................................................................................................14

3.2 Prohibited uses .............................................................................................................................................15

3.3 Life cycle of fan .............................................................................................................................................15

3.4 Technical specicaons ............................................................................................................................15

3.4.1 Technical data 50 Hz fans (metric) .........................................................................................15

3.4.2 Technical data 60 Hz fans (metric) .........................................................................................16

3.4.3 Technical data 60 Hz fans, 380 V (metric) ..........................................................................17

3.4.4 Technical data 60 Hz fans (imperial) .....................................................................................17

4 Installaon ......................................................................................................................................................................18

4.1 Delivery check ...............................................................................................................................................19

4.2 General informaon ..................................................................................................................................19

4.2.1 Fan orientaon .................................................................................................................................19

4.2.2 Standard fan outlet posion for NCF fans .........................................................................19

4.3 Installaon types .........................................................................................................................................20

4.4 Transport ..........................................................................................................................................................21

4.4.1 Transport and liing ......................................................................................................................21

4.4.2 Liing NCF fans .................................................................................................................................21

4.4.3 Storage in a warehouse ...............................................................................................................22

4.5 Mounng .........................................................................................................................................................22

4.5.1 Outdoor installaon ......................................................................................................................22

4.5.2 Minimum distances between components .....................................................................22

4.5.3 Electrical connecons ...................................................................................................................23

4.5.4 Motor connecons .........................................................................................................................23

4.6 Connecon to ducts ...................................................................................................................................23

4.7 Checks to be made before and aer starng ..............................................................................23

4.7.1 Preliminary checks..........................................................................................................................23

4.7.2 Checks to be carried out with the fan running ...............................................................24

4.7.3 Visual checks on guards ...............................................................................................................24

5 Use ......................................................................................................................................................................................25

6 Maintenance .................................................................................................................................................................25

6.1 Visual inspecons on blades and casing.........................................................................................27

6.2 Checking and cleaning parts in contact with the uid ............................................................27

6.3 Disassembly ....................................................................................................................................................28

6.3.1 Intake nozzles ....................................................................................................................................28

6.3.2 Housing .................................................................................................................................................28

6.3.3 Impeller ................................................................................................................................................28

6.4 Flexible an-vibraon joints between the fan and ducng .................................................28

6.5 Technical enclosures ..................................................................................................................................28

6.6 Spare parts ......................................................................................................................................................29