1

Newmar • PO Box 1306, Newport Beach, CA 92663

• Phone: 714-751-0488 • E-mail: techservice@newmarpower.com

TABLE OF CONTENTS

Section Description Page

1

Receiving Instructions ............................................................................................................. 2

2

Scope.......................................................................................................................................2

3

System Overview .................................................................................................................... 3

4

Installation................................................................................................................................3

4.1

Unpacking & Installing in Frame ........................................................................................... 3

4.2

AC Cabling.............................................................................................................................. 4

4.2.1

Upstream Over-current Protection............................................................................. 5

4.3

DC Cabling.............................................................................................................................. 6

4.3.1

Terminal Block Labeling………………

.....................................................................6

4.3.2

Terminal Block Max Wire Size/Recommended Torque……………………………..6

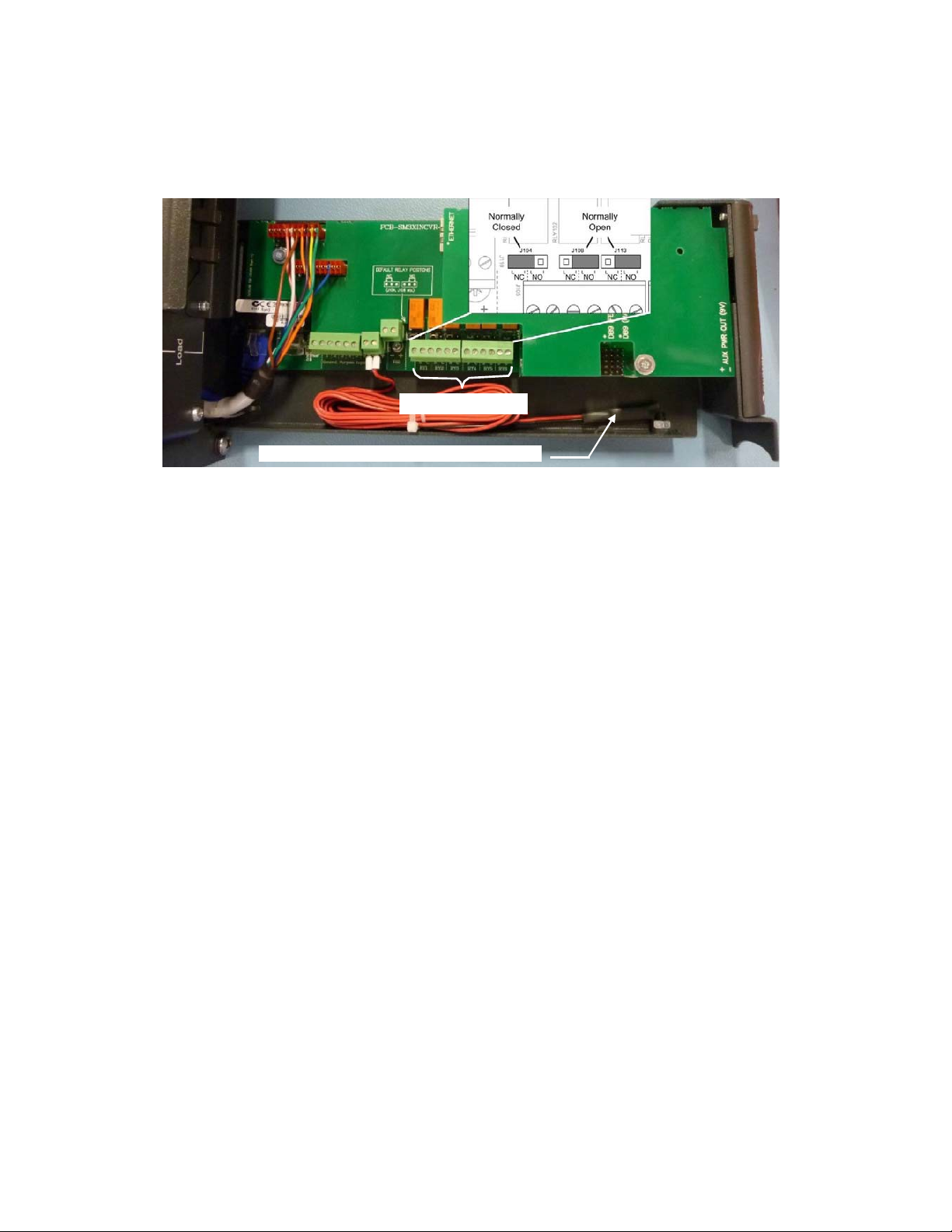

4.4 Alarm/Ancillary Cabling.......................................................................................................... 8

5

LVD Operation ......................................................................................................................10

6

Commissioning ......................................................................................................................11

7

Appendix 1 – Newmar Essential System Set – Up Parameters ....................................... 18

8

Appendix 2 – Maintenance .................................................................................................. 20

9

Appendix 3 – AC Input Transient Protection ...................................................................... 21

10

Appendix 4 – Rectifier Input Fuse Curves .......................................................................... 23

11

Appendix 5 – Installation of AC JunctionBox.......................................................................24

12

Appendix 6 – Troubleshooting .............................................................................................. 25

13

Appendix 7 – Field Replacement of Load Circuit Breakers.................................................26

14

Appendix 8 – System Wiring Diagrams............................................................................... 27

InstallationCD

You may have received a CD with your Centurion II Power System. This contains the user manuals relevant to the

System you have purchased, plus the SM3x Configuration Software. This software enables direct communication

from your computer to the SM3x via the USB port.

Note: You will require Administrator rights on your computer to install this software.

If this is the first time you have used the SM3x Configuration Software, then the installation process will guide you

through the installation of:

the USB drivers,

the Microsoft .Net Framework

the SM3x Configuration Software itself

Upon inserting the CD, open the file directory. In the root directory there is a file called Setup_sm3xconf_4.2.exe.

Double click on this and you will be guided through the installation process. Normally, you should only be required to

click “next” on all prompts.

The number “...4.2” denotes the release issue of the Configuration Software (the file you receive may be 4.3, 4.4 or

greater). If you have an earlier version installed than the number denoted there, then you can automatically update

your existing software by double-clicking on this .exe file (it will not re-install your USB drivers or the .Net

Framework).

The first time you connect your computer to a SM3x via the USB, Windows will “find new hardware”. Proceed to

install the drivers “automatically”. If, during this process, you get a message from Windows stating that the driver is

unsigned, it is not a problem. You must continue with the driver installation.