NewMar Power System Manual M-CMDRII 063022 Page 6 of 43

Model: COMMANDER II AND COMMANDER II+ Version 1.0

3RECEIVING INSTRUCTIONS

NewMar provides all equipment to the delivering carrier securely packed and in perfect condition. Upon

acceptance of the package from NewMar, the delivering carrier assumes responsibility for its safe arrival.

Once the equipment is received, it is the recipient’s responsibility to document any damage the carrier may

have inflicted, and to file the claim promptly and accurately.

NOTE: the period to make a claim against damage by a transport carrier can be short, a matter of days, and

varies by transport method, the transport contract, and local laws.

3.1 Package Inspection

Examine the shipping crate or carton for any visible damage: punctures, dents and any other signs of possible

internal damage.

Describe any damage or shortage on the receiving documents and have the carrier sign their full name.

3.2 Equipment Inspection

Open the crate or carton and inspect the contents for damages. While unpacking, be careful not to discard

any equipment, parts or manuals. If any damage is detected, call the delivering carrier to determine the

appropriate action. They may require an inspection.

NOTE: Save all the shipping materials for the inspector to see.

After the inspection has been made, if damage has been found, contact NewMar. We will determine if the

equipment should be returned to our plant for repair or if some other method would be more expeditious. If

it is determined that the equipment should be returned to us, ask the delivering carrier to send the packages

back at the delivering carrier’s expense.

If repair is necessary, we will invoice you for the repair so that you may submit the bill to the delivering

carrier with your claim forms.

It is your responsibility to file a claim with the delivering carrier. Failure to properly file a claim for shipping

damages may void warranty service for any physical damages later reported for repair.

3.3 Handling

Handle the equipment with care. Do not drop or lean on front panel or connector. Keep away from moisture.

3.4 Identification Labels

Model number and serial number are clearly marked on all equipment. Please refer to these numbers in all

correspondence with NewMar. Ideally provide a photograph of the product label for reference.

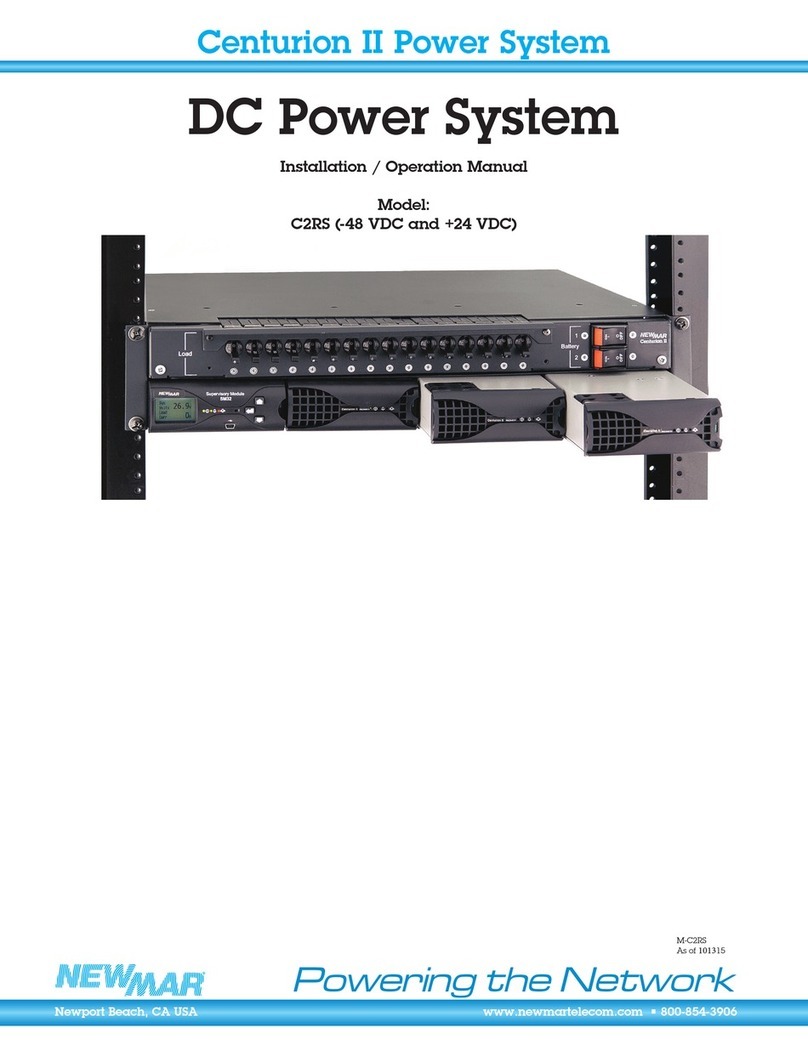

4SCOPE

This manual covers essential information for the installing and commissioning of the NewMar Power System

Commander II (CMDRII) and Commander II+ (CMDRII+) where the significant difference between the systems

is the number of rectifier shelves and the presence of a DC-DC converter shelf, respectively.

NOTE: System set-up for the controller, power modules and other ancillary devices are provided in separate

manuals. Where appropriate these are supplied with the system.

IMPORTANT: this is a generic manual. The Commander II & II+ systems can be configured with a wide range

of options. Should this manual not cover any part of the functionality of your system please contact your

NewMar representative or sales@poweringthenetwork for further information as required.

5SYSTEM OVERVIEW

The Commander II range is designed to allow a customized DC power solution with all the benefits of a

standard “off the shelf” system.

The system is intended to be a complete power system in a box with no connections needed to be made

internally. The system is designed to be extremely simple to install and set up.