Scotsman™Manual / 0960.0416

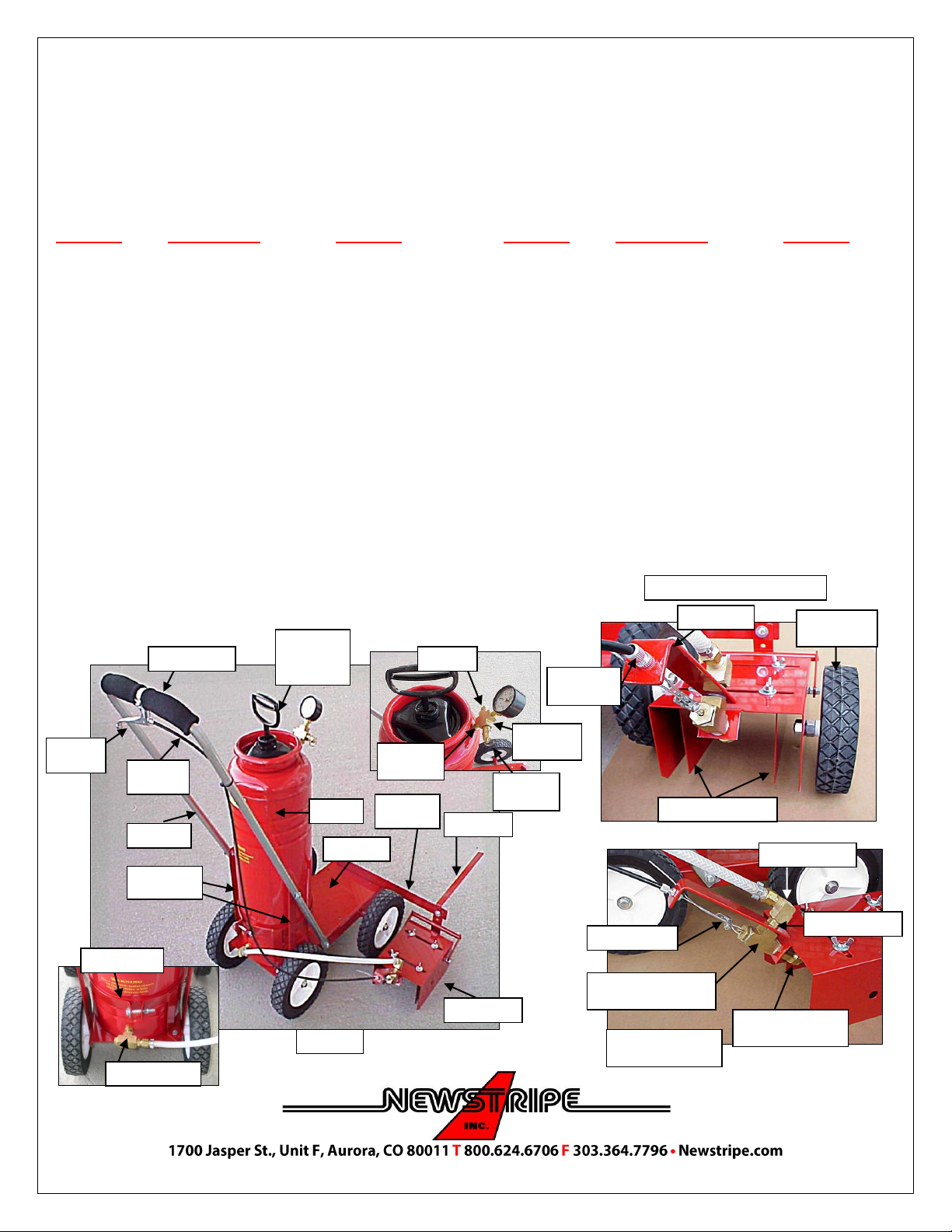

Scotsman™

ALWAYS wear safety goggles or protective eye-wear when operating the unit!

OPERATION

We recommend spraying with water first to become familiar with operation.

1. Open paint tank (5) by turning the pump/lid handle (4)

counter clockwise until loose, (triangle clamp should

turn freely) then remove.

2. Replace pump/lid assembly (4) into tank (5). Turn the

triangle clamp clockwise into the lowest locking slots in

the tank opening. If it is too high to go into the lowest

locking slot, turn the handle counter clockwise while

holding triangle clamp to loosen the pump nut. Once

the triangle clamp is in the lowest locking slots, turn

the pump handle clockwise until snug. DO NOT OVER

TIGHTEN. Never use any kind of tool to tighten the

pump lid.

3. Hand pump up and down until the desired pressure is

reached. Normal operating pressures are 20-35 psi.

NEVER PRESSURIZE ABOVE 35 psi. The pressure you

select will be dependent on the type and viscosity of

your paint, the speed you walk, etc.

4. Check for any leaks. The pump/lid should seal with

normal hand pressure. Never use pry bars, other tools

or excessive force to close. If necessary clean gasket,

gasket seating area and lubricate or replace the gasket.

5. Pull the control lever (1). An even flow of paint should

spray from the nozzle (12) contacting the bottom edge

of both adjustable spray shields inside spray box (10).

6. View the spray pattern. Ideally, the spray will look like

picture # 1 in "Surface and Paint Preparation guide".

It might be necessary to thin the paint or increase the

pressure to get the proper pattern.

7. The adjusting tab that the spray valve assembly (11)

mounts to, should only be bent up or down to adjust

spray pattern so that the spray strikes the surface at

the midpoint of the spray box. NOTE: Spray pattern

should be adjusted so that spray is hitting ground and

bottom edge of spray shields at the same time.

Activate trigger and paint (or water) will spray from

the gun.

8. Spray Box (10) can be adjusted from 2" to 6". Loosen

wing nuts on top of spray box and slide baffle plates in

or out to the desired width and retighten wing nuts.

The nozzle for 4” wide lines is installed at the factory.

For 2” or 6” wide lines, select the proper nozzle from

the Spray Head Adjustment page. For 6” lines remove

both baffle plates from spray box.

9. When low on paint the unit will begin to "sputter" and

paint will come out unevenly. To refill, pull ring on

pressure relief valve (18) to release the tank pressure.

Turn the pump/lid handle counter clockwise and

remove it from the tank. Refill with thinned, strained

paint and re-pressurize.

OPERATIONAL NOTE!

Note: The pump nut unscrews from the triangle to loosen the lid, but will not

come off. Pour properly thinned paint (See Surface and Paint Preparation) into

the paint tank. If this is your first time, use water to practice

NEVER PRESSURIZE ABOVE 35 psi.

Never use any kind of tool to tighten the pump lid.

Lubricate gasket with petroleum jelly

NEVER try to open tank when pressurized.

ALWAYS strain the paint.