4600™ Self-Propelled Airless Sprayer

ALWAYS wear safety goggles or protective eye-wear when operating the unit!

4600™ SP Manual / 3031.0623

Page 4 of 10

SPRAY TIP CLEANING DURING USE

1. Place the Spray Control Knob in the re-circulating

position, and then squeeze the spray trigger lever to

release the pressure from the system.

5. Turn the Prime/Spray knob to the spray position and

resume spraying. If the spray gun continues to clog,

check the filter in the gun handle.

2. Turn the spray tip arrow on the spray gun so that the

arrow points toward the gun.

6. Turn the Prime/Spray knob to the prime position. Turn

off the machine. Remove the paint hose from the

spray gun.

3. Turn the spray control knob to the spray position and

trigger the gun. This should clear the gun. Turn the

spray control knob to the prime position and trigger

the gun to release the pressure.

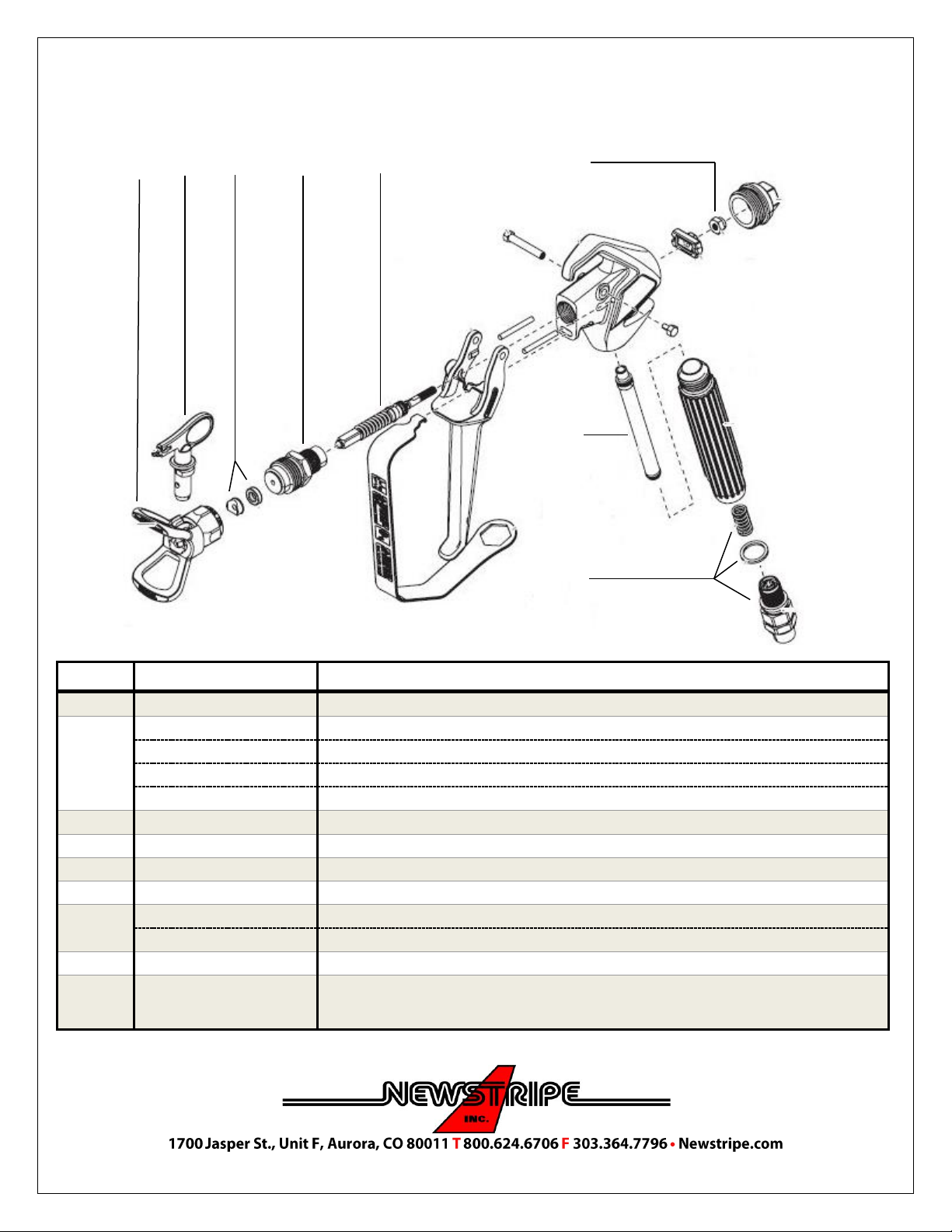

7. Press the trigger lock on the side of the spray gun to

lock the spray trigger. Remove the gun from the gun

mount. Push forward on the spray trigger guard to

release the guard from the front of the gun.

4. Reverse the spray tip so that the spray tip arrow points

toward the ground.

8. You can now unscrew the handle. The filter pulls

straight out of the handle. Only rinse the filter to clean

it. If the filter is still clogged, collapsed or dented,

replace the filter. Reinstall the filter. If there are still

issues, proceed to the cleaning procedure.

CLEANING PROCEDURE

1. Remove the pail with paint.

2. Place an empty pail on the machine and fill it with 2 gallons of water if using latex paints. If using an

alkyd or oil base paint, use enough of the appropriate solvent, that suction filter is covered.

3. Place the return hose in a waste container.

4. Make sure the Spray Control Knob is in the Prime/Re-circulating Position.

5. Start the engine and let it run in the prime position until the fluid in the return hose runs clear.

6. Turn the Spray Control Knob to the Spray Position.

7. Trigger the gun until the gun spray runs clear.

8. Turn the spray control knob to the prime position, turn off the engine, and then trigger the spray gun

to release the system pressure.

9. Wipe down the suction tube and return hose.

10. Clean the spray tip if needed with a nylon bristle brush. DO NOT USE METAL BRUSHES

PRECAUTIONARY WARNING

ALWAYS release the pressure in the system before changing or cleaning

the spray tip. (Place the Spray Control Knob in the re-circulating position,

turn off the sprayer and squeeze the spray trigger to release the pressure)

NEVER use fuels to clean the equipment

DO NOT use solvents containing halogenated hydrocarbons such as methyl

bromine, carbon tetrachloride and ethyl iodine

DO NOT attempt to clean a clogged gun filter. You must replace it.

DO NOT use brushes with metal bristles or any metal object to clean the

spray tip of dried paint. Replace the tip if it cannot be cleaned!