NexSens X2-CB User manual

Other NexSens Data Logger manuals

NexSens

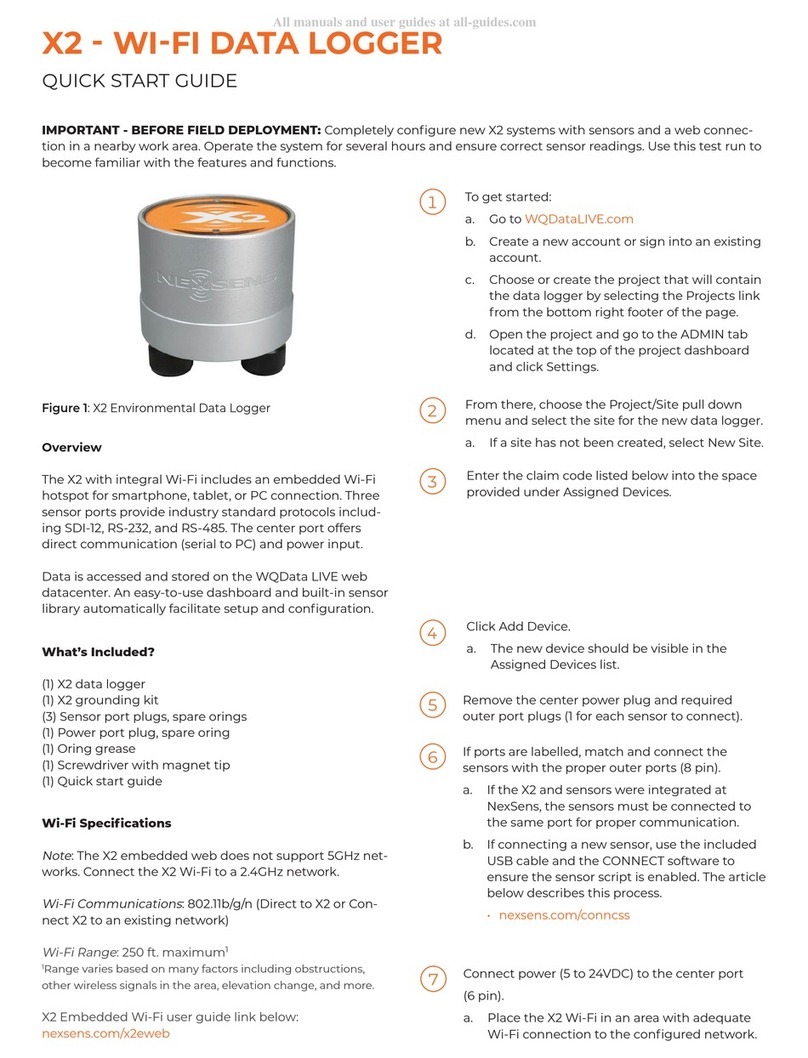

NexSens X2 User manual

NexSens

NexSens X2-Cell User manual

NexSens

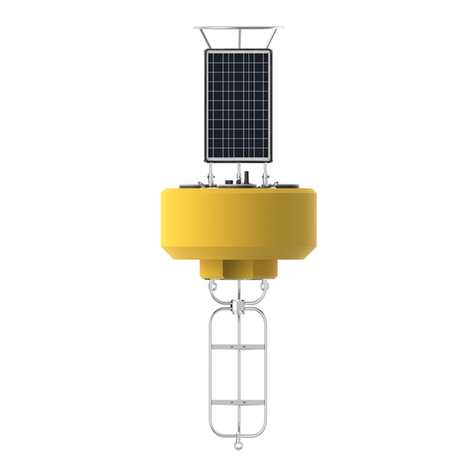

NexSens CB-1250 Data Buoy User manual

NexSens

NexSens X2 User manual

NexSens

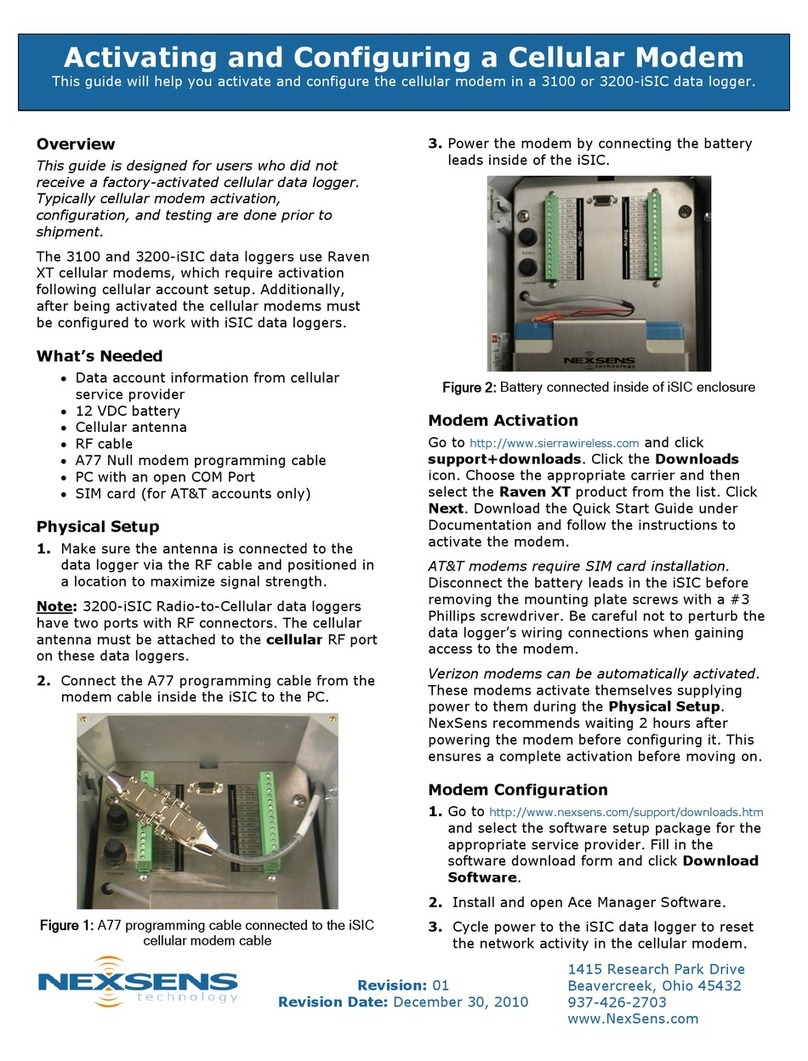

NexSens 3100-iSIC User manual

NexSens

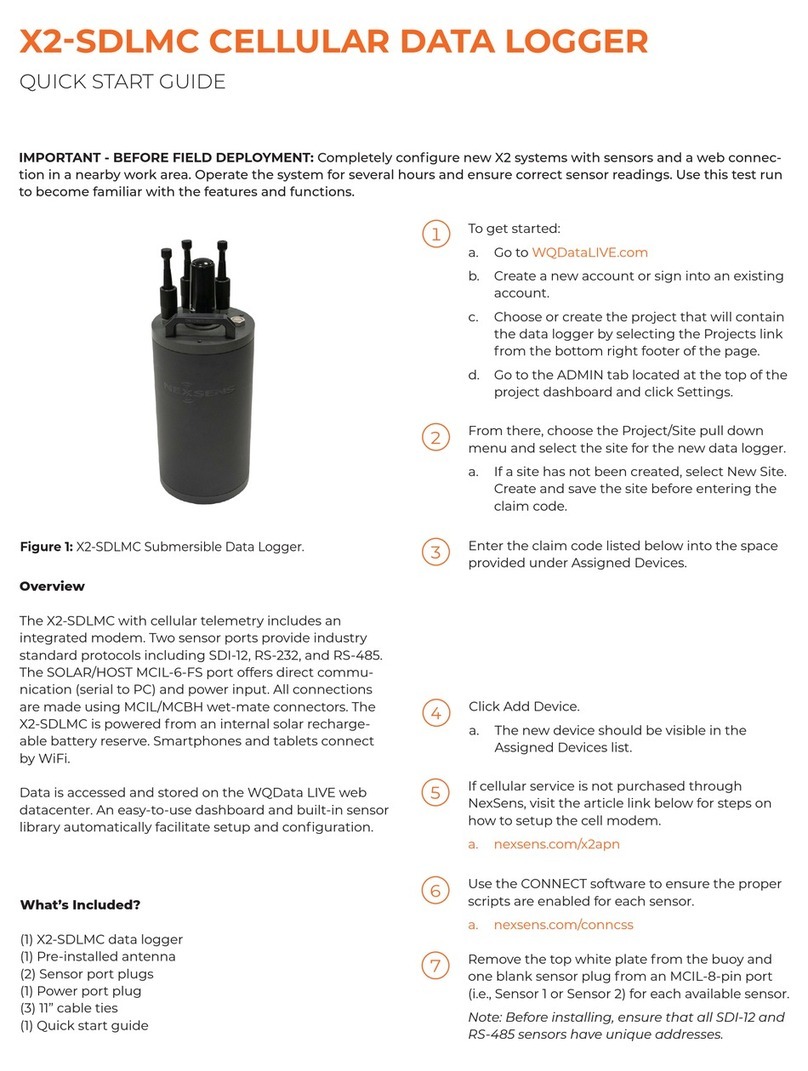

NexSens X2-SDLMC User manual

NexSens

NexSens X2 User manual

NexSens

NexSens X2-SDL User manual

NexSens

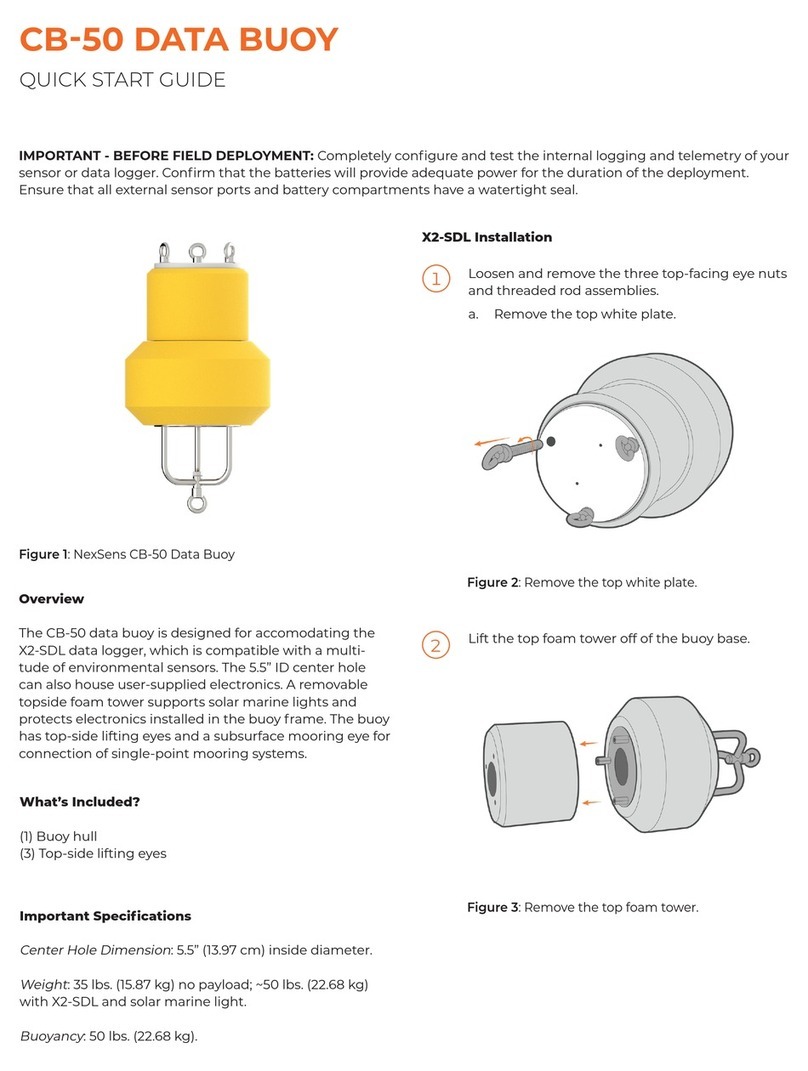

NexSens CB-50 Data Buoy User manual

NexSens

NexSens X2 User manual

NexSens

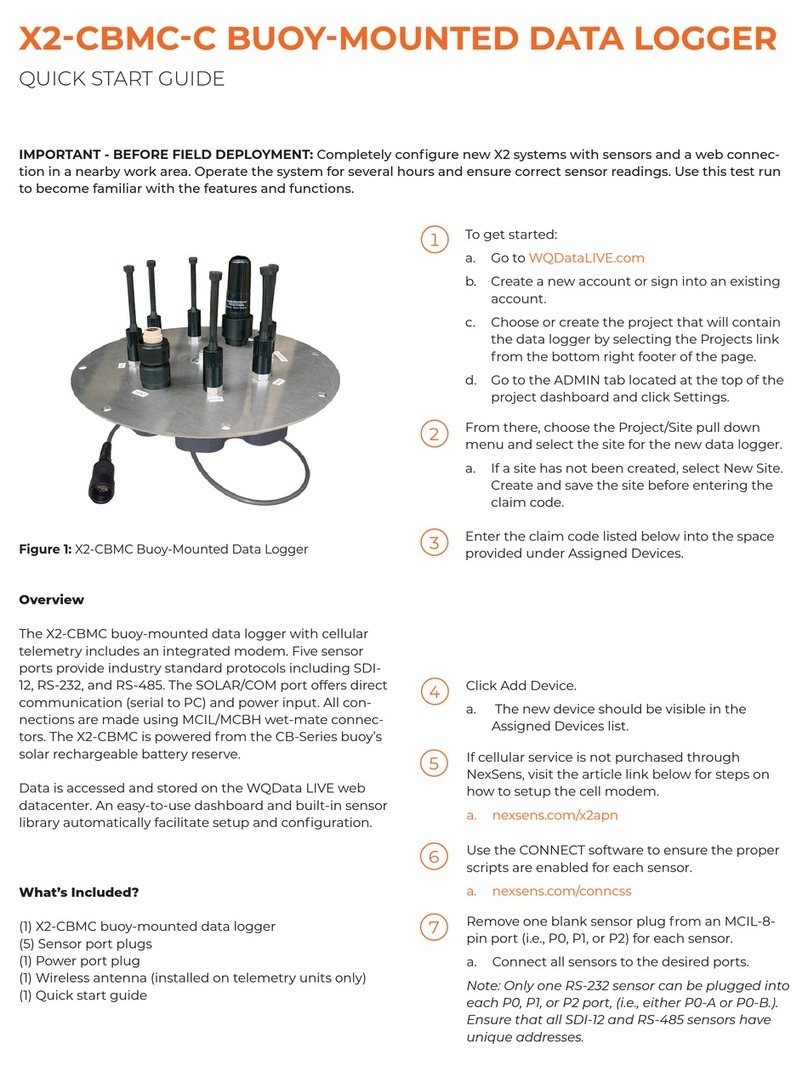

NexSens X2-CBMC-C User manual

NexSens

NexSens X2 User manual

NexSens

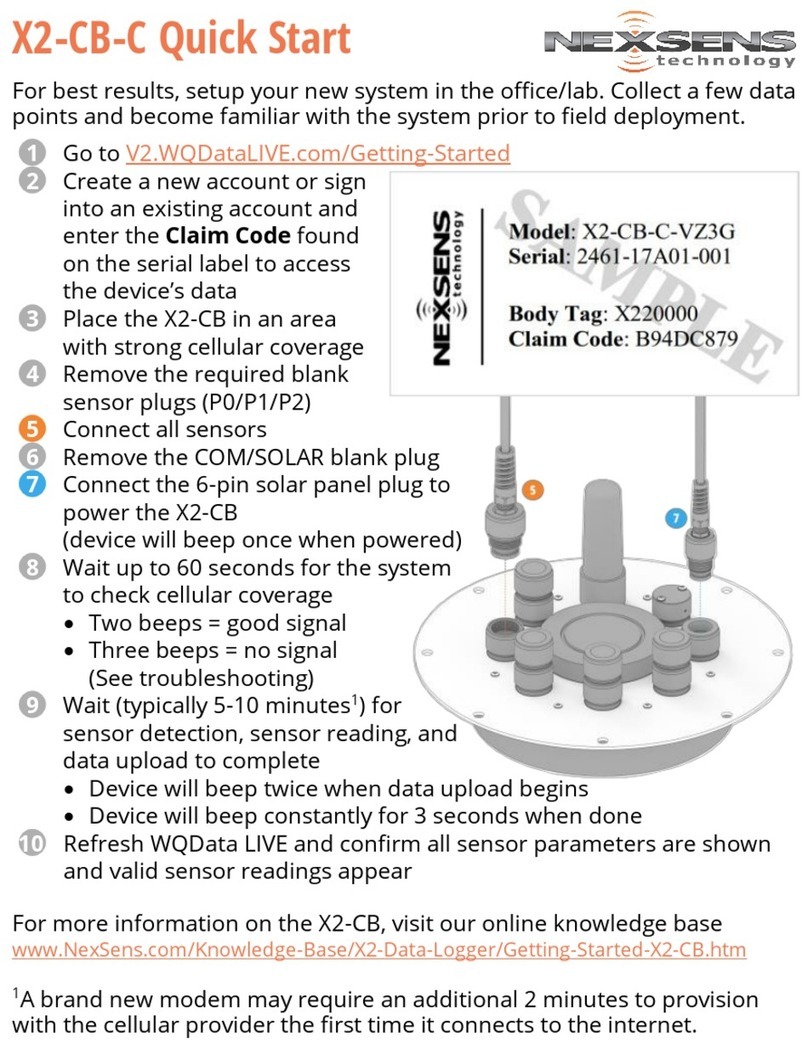

NexSens X2-CB-C User manual

NexSens

NexSens CB-150 Data Buoy User manual

NexSens

NexSens CB-1250 Data Buoy User manual

NexSens

NexSens X2-SDL User manual

NexSens

NexSens X2 User manual

NexSens

NexSens X2 User manual

NexSens

NexSens X2 User manual

NexSens

NexSens SDL500 User manual