General points for the installation engineer

Inspection of the installation

Current regulations require the heating installation to be

inspected before it is commissioned. The inspection must

be carried out by a suitably qualified person and should

be documented. The above applies to closed heating sys-

tems.

If AMB 30 is replaced, the installation must be inspected

again.

For outdoor air systems (not hybrid systems) NIBE F1330

(serial number from 06510X10263YYY, where X is 0, 1, 2

or3 and YYY is a serial number) must be connected to a

prepared low pressure switch. Heat pumps manufactured

earlier do not have this extra low pressure switch and

cannot be used in an outdoor air system with AMB 30.

Assembly

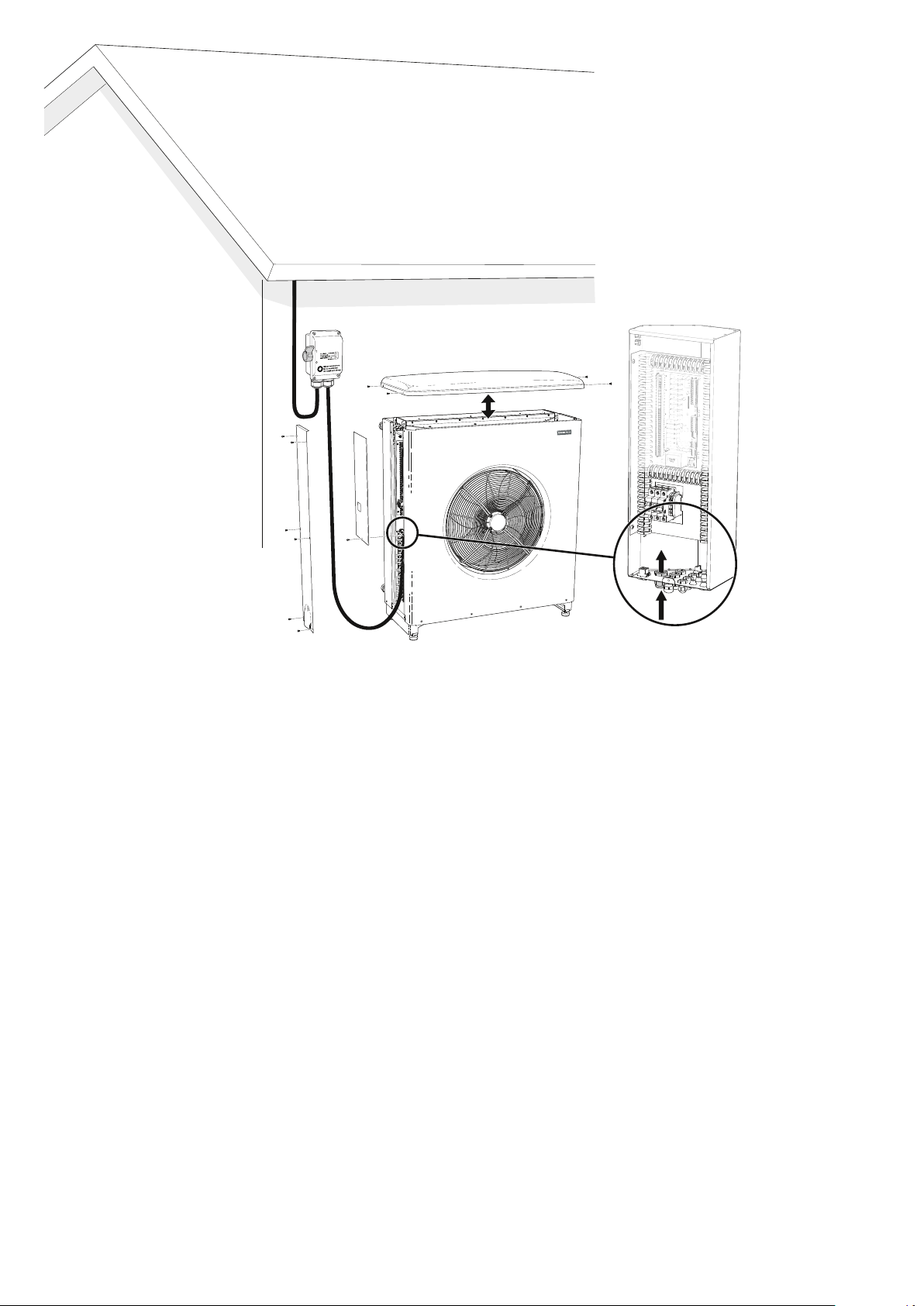

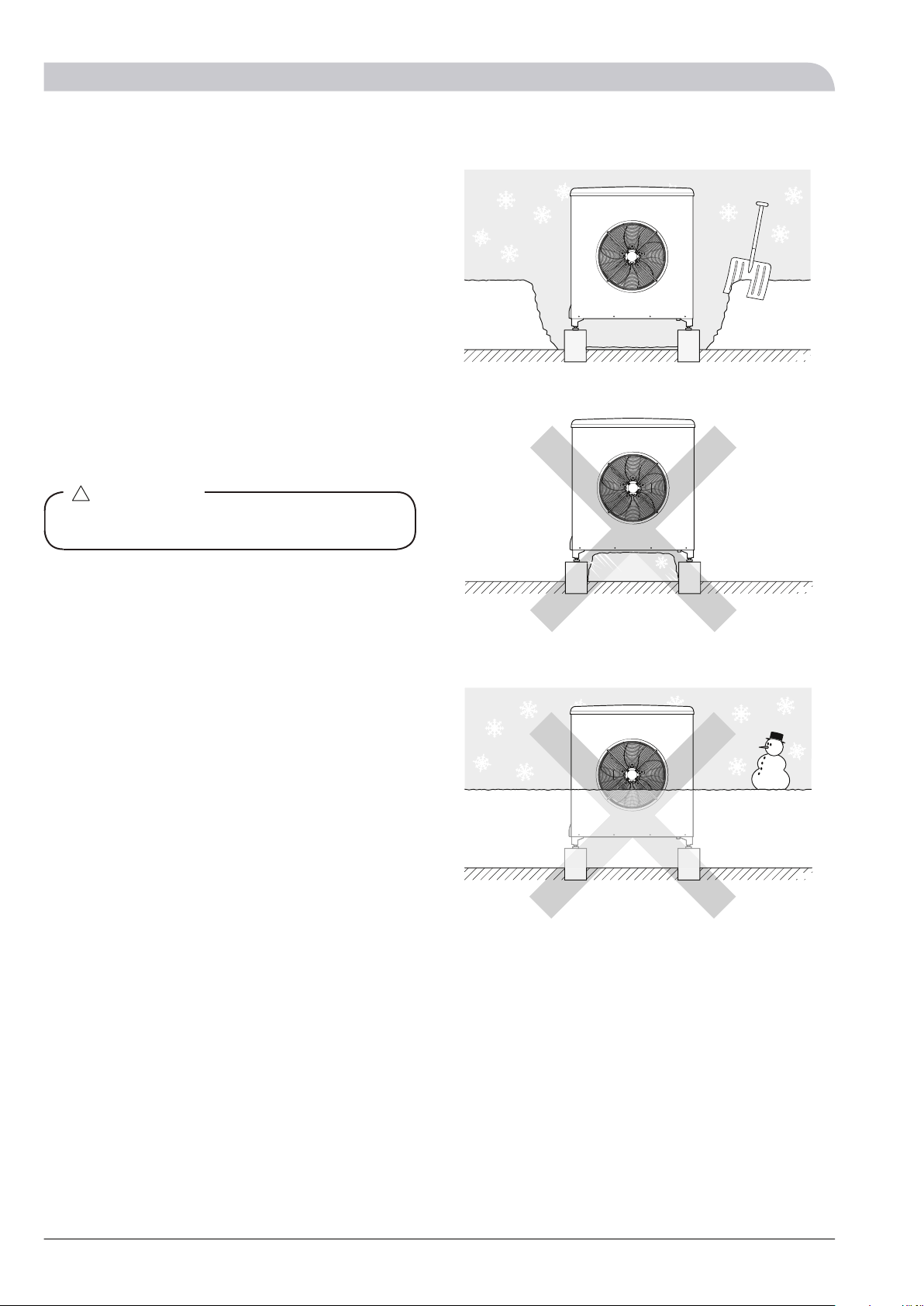

AMB 30 should be installed outdoors on a firm and level

surface, preferably a concrete foundation with ground

stand or wall mounting. The AMB 30 should not be posi-

tioned next to sensitive walls, for example, next to a bed-

room. Also ensure that the placement does not inconveni-

ence the neighbours.

Large amounts of condensation water as well as melt

water from defrosting can be produced. Provide good

drainage at the installation area and make sure water

cannot run out onto paths or the like during periods that

ice can form. Ideally condensation water is led off to a

drain or similar.

The distance between AMB 30 and the house wall must

be at least 400 mm. Clearance in front of AMB 30 should

be at least one metre. AMB 30 must not be placed so

that recirculation of the outdoor air can occur. AMB 30

must not be placed in a windy location where it is ex-

posed to direct strong winds. This causes lower output

and impaired efficiency.

Control

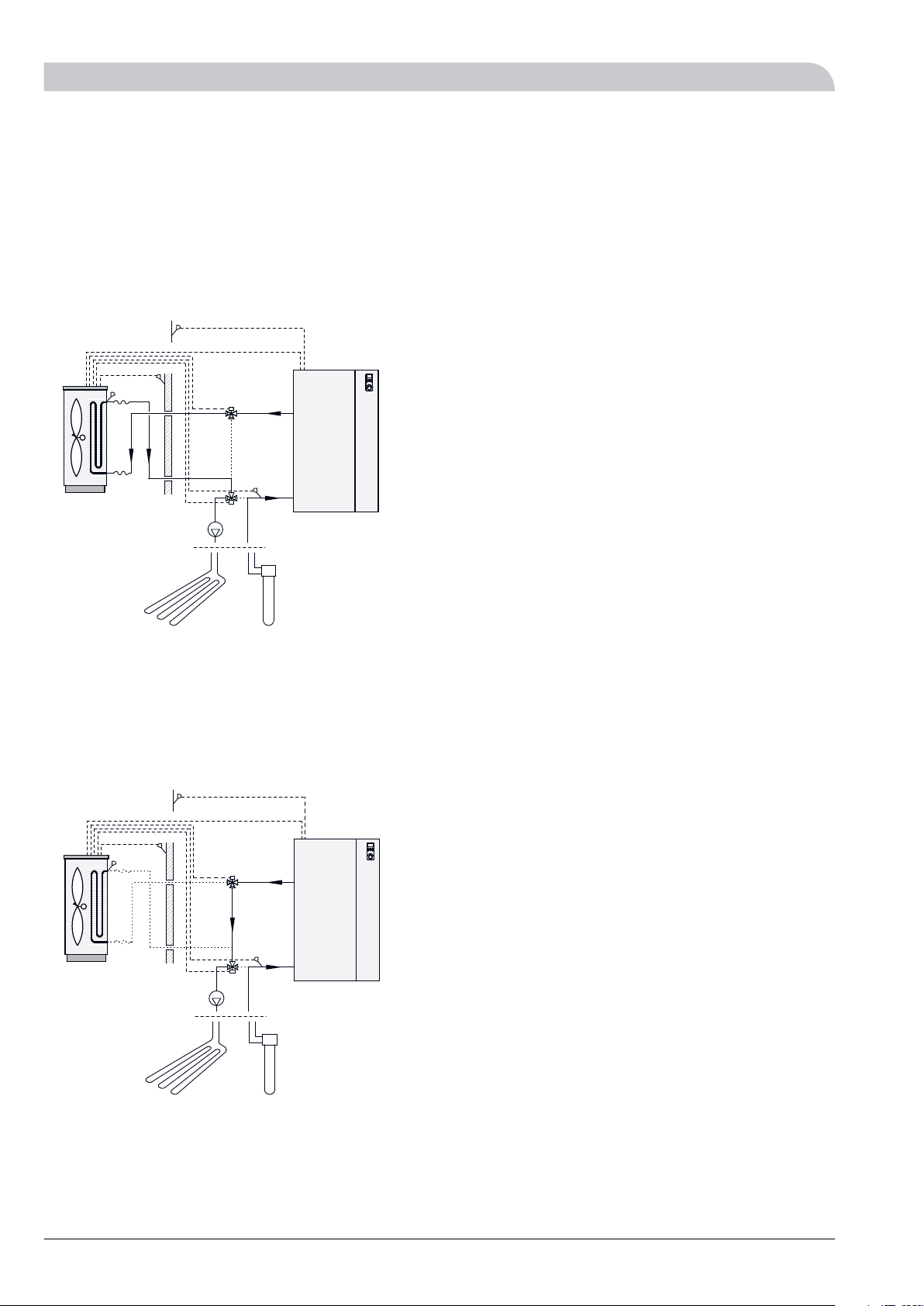

AMB 30 is equipped with an internal electronic controller

that handles all functions necessary for operation.

Defrosting, stop at max/min temperature, circulation

pumps, reversing valves, blocking of the compressor in

NIBE F1330 as well as enabling the heater for the drip pan

are controlled accordingly.

The integrated controller is set via the control unit (located

indoors) during installation and can be used during service.

400 mm

400 mm

3 m

Fritt utrymme

Fritt utrymme framför

Serviceutrymme

800 mm

Min. avstånd

vid användning

av flera AMB30

)UHH VSDFH

6HUYLFH DUHD

)UHH VSDFH LQ IURQW

0LQ GLVWDQFH ZKHQ XVLQJ VHYHUDO $0%

7AMB 30

For the Installer

General points for the installation engineer