10 NIBE BA-SVM 10-200Section 4 |

4 Pipe connections

General information

Pipe installation must be carried out in accordance with

the current standards and directives.

The pipe dimensions should not be less than the rec-

ommended pipe diameter according to the table below.

However, in order to achieve the recommended flow,

each installation must be dimensioned individually.

The system can be used with a low- and medium-tem-

perature climate system. The recommended tem-

perature of the heating medium at the dimensioned

outdoor temperature DOT must not exceed 55°C on

the supply and 45°C on the return circulation from the

climate system. BA-SVM 10-200 can reach up to 65°C

when using the electric additional heat or another peak

heat source.

An overflow pipe must be routed from the safety valve

to a suitable drain. The entire length of the overflow

pipe must be inclined towards the floor drain to pre-

vent water pockets and must also be frost-proof. In or-

der to reach maximum system efficiency, we recom-

mend installing BA-SVM 10-200 as close as possible to

the outdoor heat pump.

The BA-SVM 10-200 unit is not equipped with a shut-

off valve for the climate system. In order to facilitate

future servicing, the shut-off valves should be in-

stalled on the outside of the indoor unit.

The BA-SVM 10-200 unit can be docked to the central

heating, cooling operation and hot water systems. It

is absolutely necessary to install the supplied safety

assembly on connection XL11.

Air/water

heat pump

Minimum flow

during defrost-

ing

(100% pump

capacity [l/s])

Minimum

recom-

mended

pipe dimen-

sion (DN)

Minimum

recommend-

ed pipe

dimension

(mm)

BA-SVM 10-200/6

+ AMS 10-6 0,19 20 22

BA-SVM 10-200/12

+ AMS 10-8 0,19 20 22

BA-SVM 10-200/12

+ AMS 10-12 0,29 20 22

CAUTION

All high points in the climate system must be equipped

with air vents.

CAUTION

The pipelines need to be flushed out before the indoor

unit is connected so that any debris cannot damage

component parts.

CAUTION

Until the system’s heating/cooling circuit has been

filled with heating medium, the switch (SF1) in the

controller must not be set to “I” or „ ”. If you do not

comply with the above instructions, many compo-

nents of the BA-SVM 10-200 unit may be damaged.

Minimum system flow

The installation must be dimensioned at least to the

extent required to manage the minimum defrosting

flow at 100% circulation pump operation, see table.

CAUTION

An incorrectly dimensioned climate system can result

in damage to the appliance and lead to malfunctions.

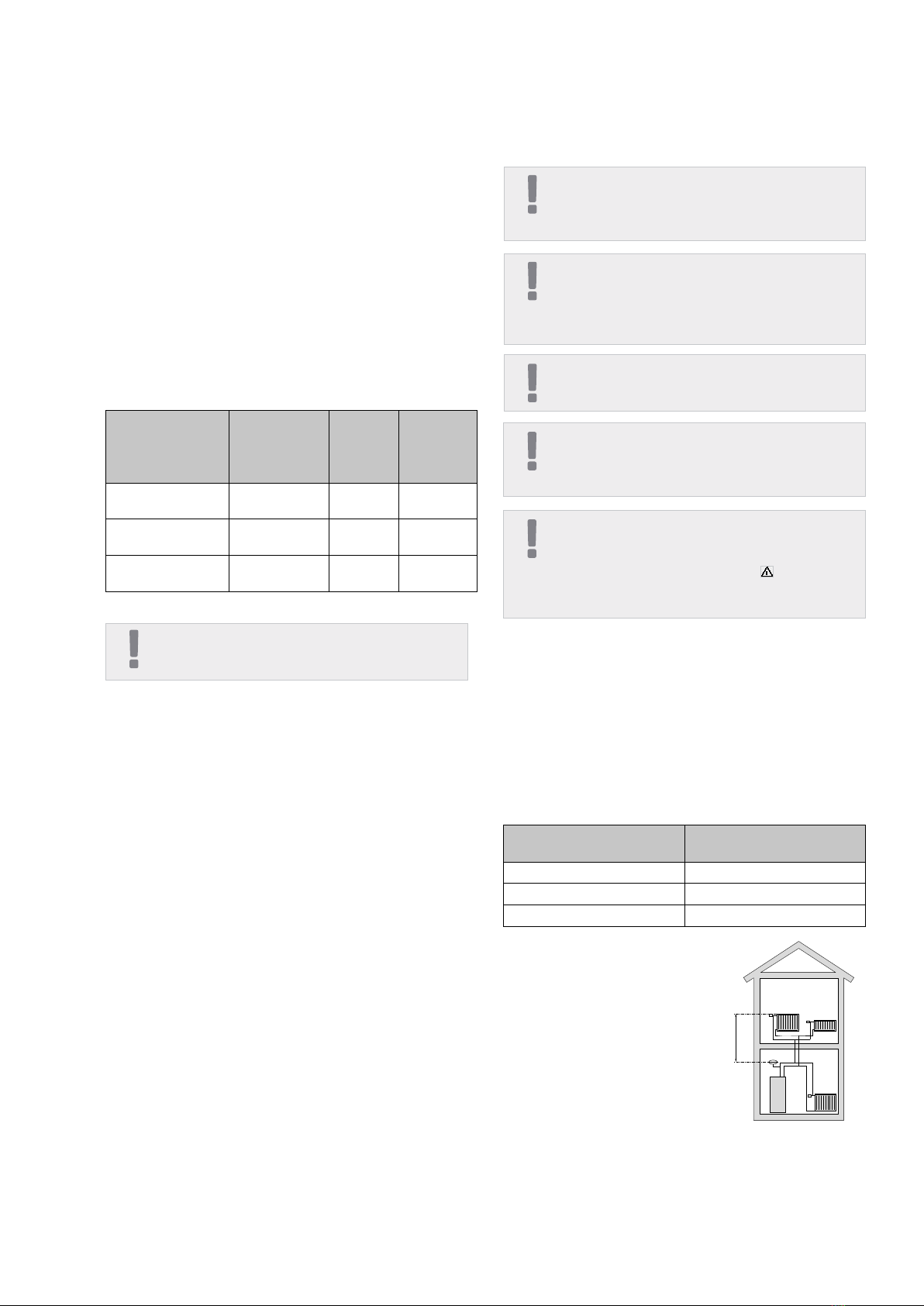

BA-SVM 10-200 is equipped

with an expansion vessel with

a 10l capacity.The pressure set-

ting in the level vessel should

be set according to the maxi-

mum height (H) between the

vessel and the highest-posi-

tioned radiator, see drawing.

An initial pressure of 0.5 bar

The expansion vessel’s volume must be at least 5% of

the system’s total volume. BA-SVM 10-200 appliances

have been equipped with an expansion vessel with a

10l volume. If the capacity of the built-in expansion

vessel is insufficient, an additional expansion vessel

meeting the above requirements should be added to

the installation.

Table with examples:

Total volume [l]

(indoor unit and climate system)

Volume [l],

expansion vessel

500 10+15

750 10+25

1000 10+40

Expansion vessel

(5 mvp) means a maximum permissible height dif-

ference of 5 m. The maximum volume of the system

without a boiler is 220 l at the above initial pressure.

Pipe connections

CAUTION

In the installation before the BA-SVM 10-200, a par-

ticulate filter should be used, dedicated for heating

installations. The filter will protect the unit against pol-

lution.

CAUTION

Ensure that incoming water is clean. When using a pri-

vate well, it maybe necessary to supplement with an

extra water filter.