3

CONTENTS (DETAILED)

A. Important Saftey and General Infromation ................................

4

A.1. Important Saftey and General Information ...........................................

4

A.2. Agency Performance Audit and Efficiency Testing Notice ...................

4

A.3. Importance of a Quality Installation .....................................................

4

A.4. Importance of Air Flow and Setup .......................................................

4

A.5. Checking Product and Inspection ........................................................

4

B. General Specifications ..............................................................

5

B.1. Saftey Warnings ...................................................................................

5

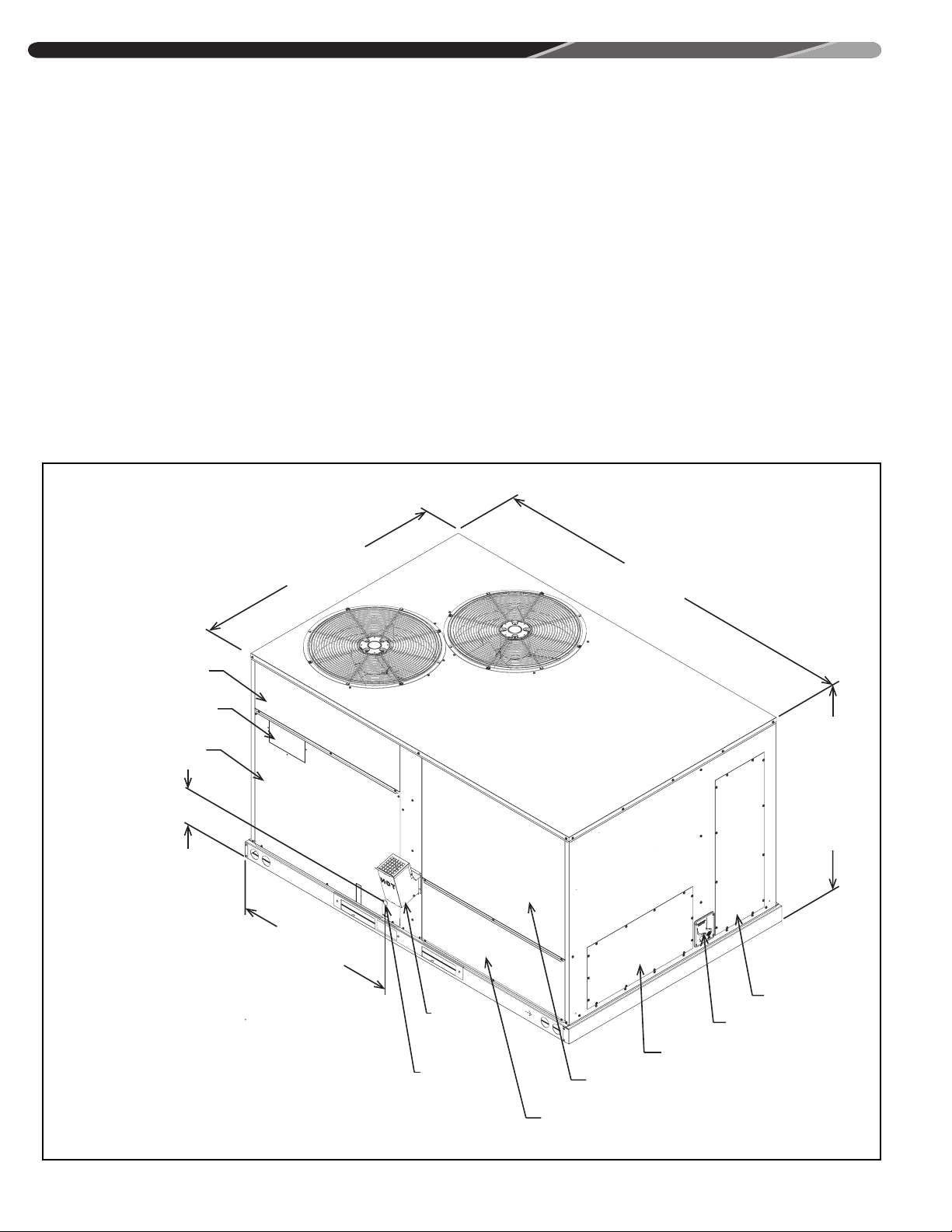

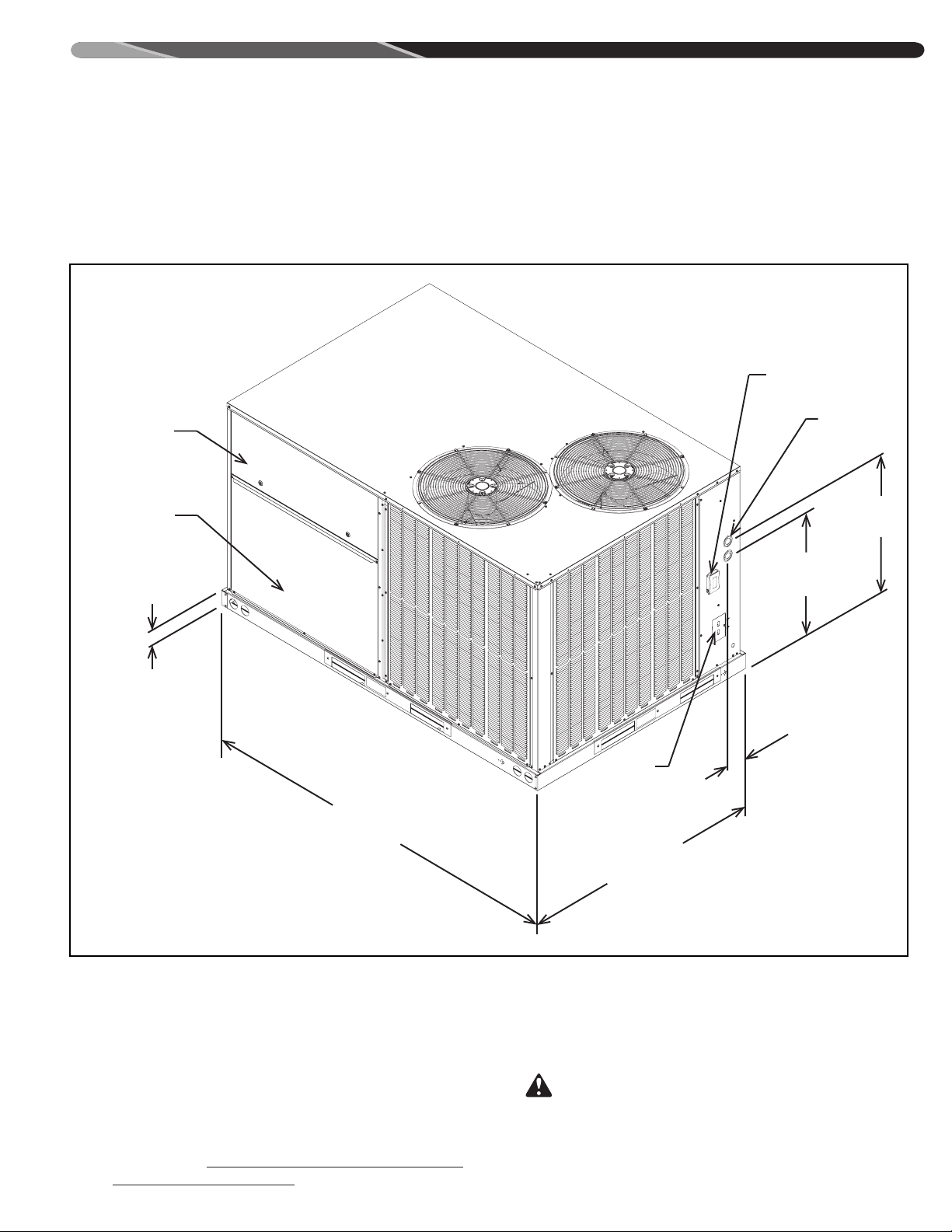

B.2. Major Components ..............................................................................

6

B.3. Product Data Information .....................................................................

6

C. Installation of the Unit ...............................................................

11

C.1. General .................................................................................................

11

C.2. Tool and Refrigerant .............................................................................

11

C.3. Choosing a Location ............................................................................

12

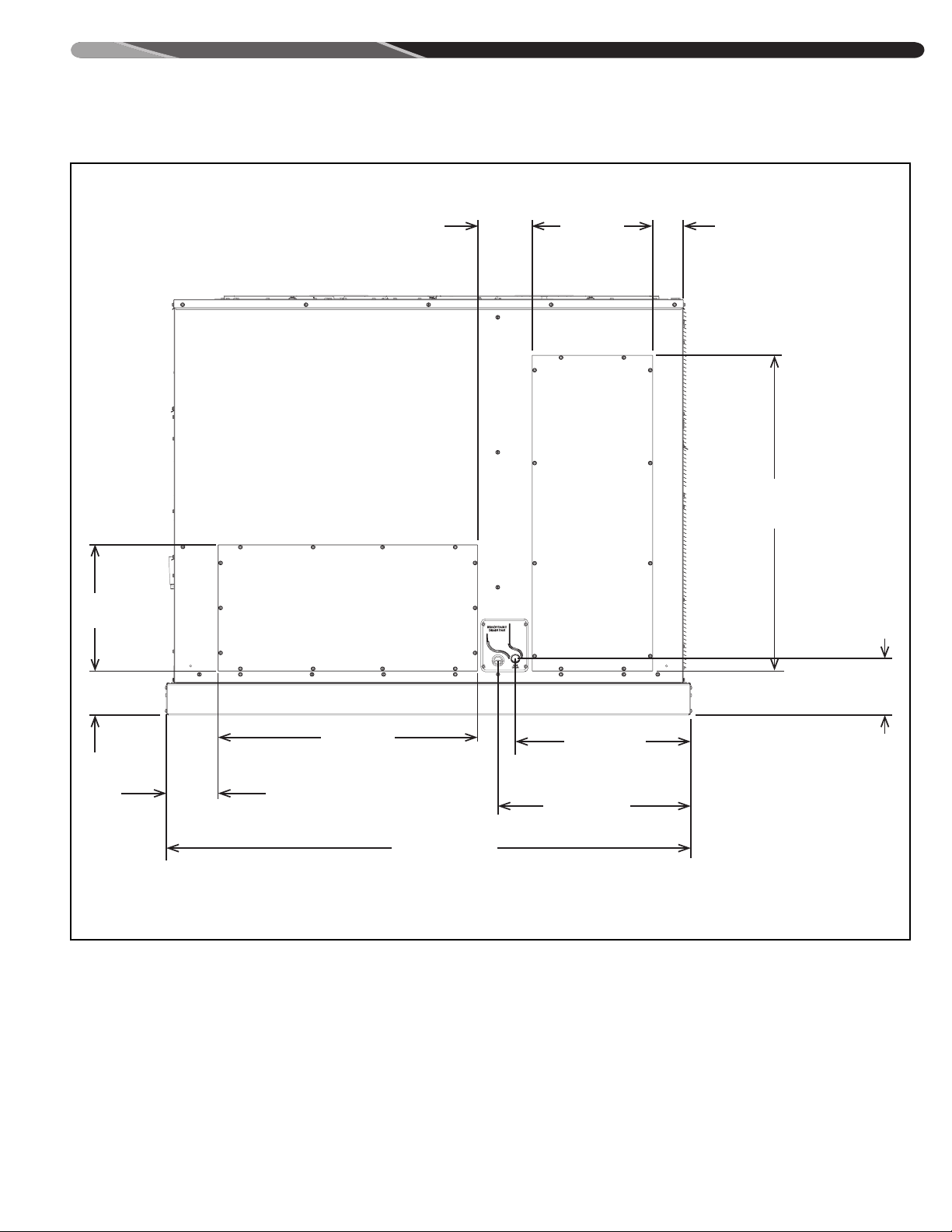

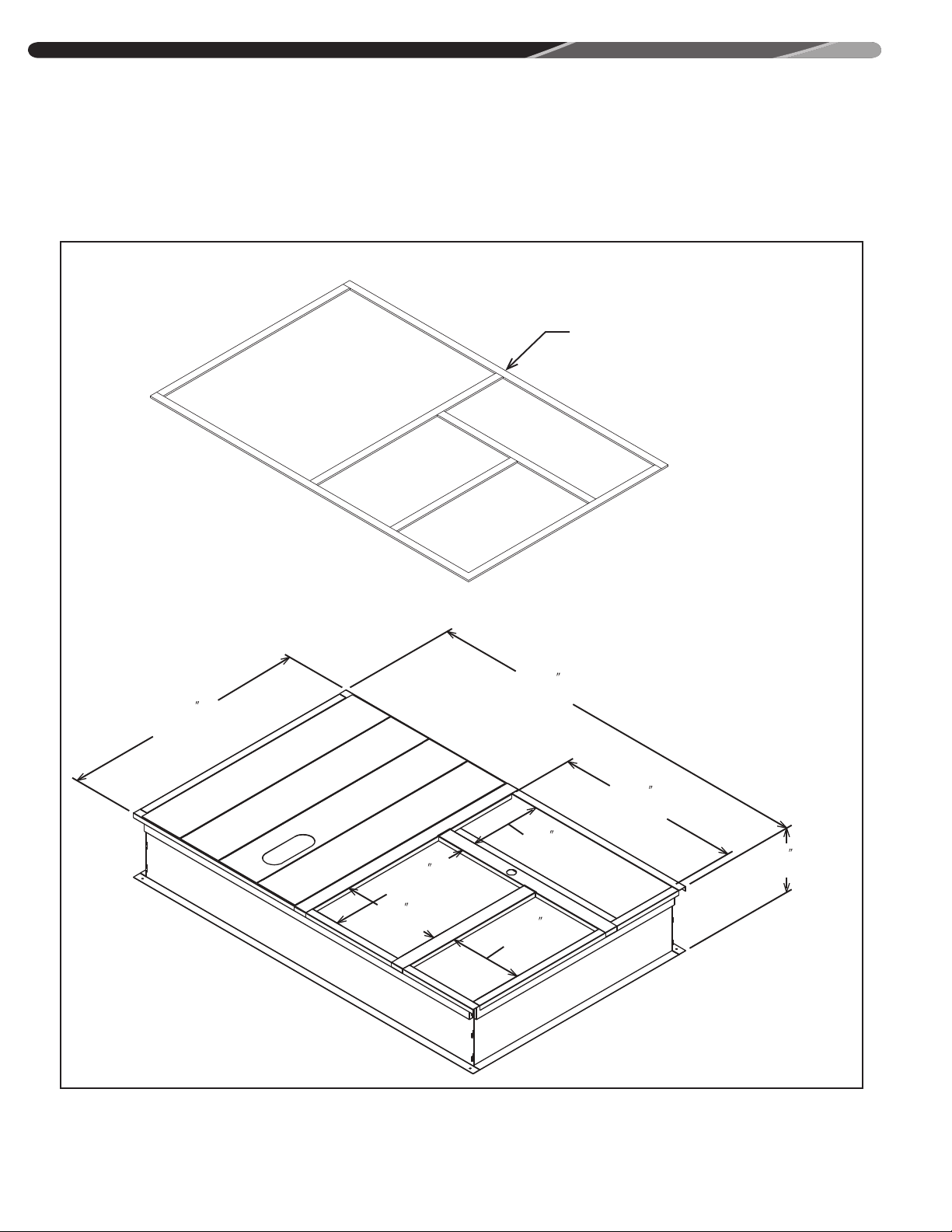

C.4. Setting the Unit ....................................................................................

14

C.5. Installing Condensate Drain .................................................................

19

C.6. Final Installation Inspection ..................................................................

20

D. Duct and Venting .......................................................................

20

D.1. Air Flow and Static Pressure ................................................................

20

D.2. Duct Requirements and Best Practices ...............................................

20

D.3. Filters ....................................................................................................

21

D.4. Economizers and Fresh Air Dampers ..................................................

23

D.5. Smoke Detectors .................................................................................

26

E. Electrical ................................................................................... 27

E.1. Electrical Saftey Information ................................................................ 27

E.2. Electrical Data ...................................................................................... 29

E.3. Electrical Connections .......................................................................... 29

F. Control/Thermostat Wiring ......................................................... 31

F.1. T-Stat Field Connections ....................................................................... 31

F.2. Routing Control Wiring .......................................................................... 33

F.3. Measuring Control Voltage Loads ......................................................... 33

G. Gas ............................................................................................ 34

G.1. Gas Piping Requirements .................................................................... 34

G.2. Procedure: Connecting Gas Lines to Gas Valve ................................. 38

G.3. LP Conversion ..................................................................................... 39

G.4. Operation and Testing ......................................................................... 40

J. Startup and Operation ............................................................... 47

J.1. Final Inspection ..................................................................................... 47

J.2. Turning on Power for the First time ...................................................... 47

J.3. Checking and Adjusting Air Flow ......................................................... 48

J.4. Checking Cooling Operation ................................................................ 50

J.5. Checking Heating Operation ................................................................ 52

K. Test and Balance ....................................................................... 55

K.1 Air Flow Charts and Information ........................................................... 55

K.2. Air Flow Adjustments ........................................................................... 55

M. Humidity Control ....................................................................... 56

M.1. Dehumidification System Information ................................................. 56

M.2. Humidity Sensor Installation ................................................................ 57

M.3. Humidity Control Settings and Configuration ..................................... 58

N. Diagnostics ................................................................................ 59

N.1. Diagnostics Chart ................................................................................. 59

N.2. Alarm Codes - Full List ........................................................................ 60

N.3. Common Mistakes ............................................................................... 74

P. Appendices ................................................................................ 75

Appendix A - General Product Data ....................................................... 75

Appendix B - Electrical Data ................................................................... 78

Appendix C - Air Flow Performance Data .............................................. 89

Appendix D - Heat & Cool Performance Data ........................................ 97

Appendix E - Gas Heat Performance Data ............................................. 116

Appendix F - Refrigerant Charging Charts ............................................. 117

Appendix G - Wiring Diagrams & Schematics ........................................ 125

Appendix J - Unit Tie-Down .................................................................... 157

R. Information for the Owner ......................................................... 162

S. Installation Check List and Job Site Sheet ........................................ 165

R.2 Product Model and Serial Number ................................................... 169

S. Installation Check List and Job Site Sheet ...............................

170