4NIBE BA-SVM 10-200

1 Important information

Safety information

Serial number

Symbols

Marking

BA-SVM 10-200 is CE marked and

has an IP21 protection rating.

The CE mark confirms that NIBE

has ensured that the product

conforms to all applicable regula-

tions specified by the relevant EU

directives. The CE mark is man-

datory for most products sold in

the EU, regardless of where they

are made.

IP21 means that objects with a

diameter greater than or equal to

12.5 mm cannot penetrate and

cause damage and that the prod-

uct is protected against vertically

falling drops of water.

This appliance can be used by

children aged 8 years and above

and persons with reduced phys-

ical, sensory or mental capacity

or lack of experience and knowl-

edge, if they will be supervised

or have received instruction con-

cerning safe use of the appliance,

and if they understand the dan-

ger involved in its use. Children

must not play with the appliance.

Cleaning and basic maintenance

of the appliance must not be car-

ried out by children unsupervised.

The rights to make structural

changes are reserved.

©NIBE 2020

This manual contains installation

and service procedures for imple-

mentation by specialists.

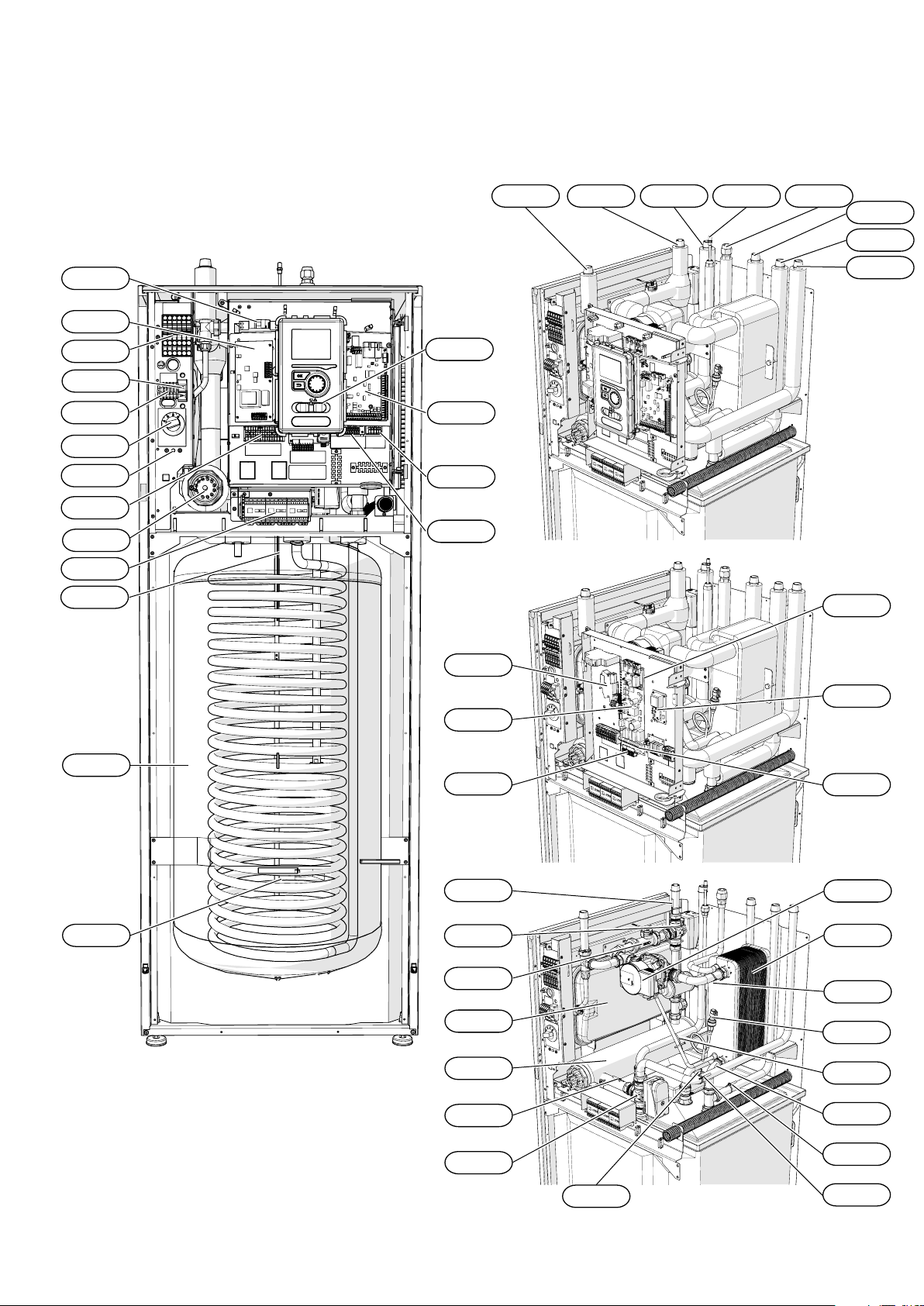

The serial number is located at

the bottom of the identification

plate, on the top cover BA-SVM

10-200 and consists of 14 digits.

CAUTION

This symbol indicates danger

to the appliance or person.

NOTE

This symbol indicates im-

portant information to note

while operating or main-

taining the appliance.

TIP

This symbol indicates tips

that will make it easier to

operate the product. Serial number

BA-SVM

(PF3)

Section 1 | Important information