5. SERVICE

Report any malfuncons in the buer tank operaon to the

authorized service centres.

The tank may only be repaired / serviced by an au-

thorized service since improper repair can cause safety

risks, and the loss of product warranty.

CAUTION

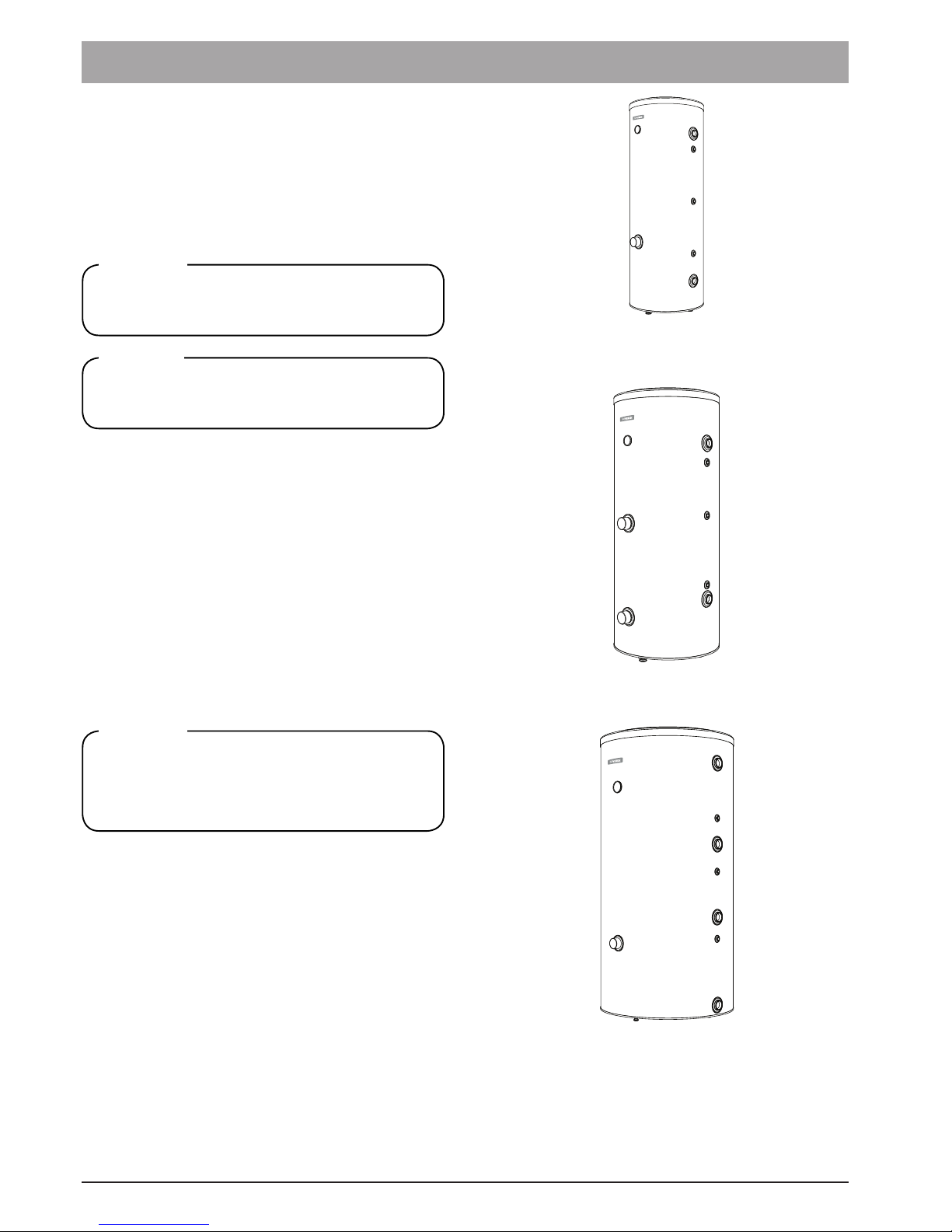

Parameter U/m Tank model

UKV 20-220 UKV 20-300 UKV 20-500 UKV 20-750 UKV 20-1000

Energy eciency class -CCCCC

Storage volume (V)* l218,3 296,0 495,6 740,7 991,0

Standing loss (S)* W77,1 94,6 97,5 122,5 140,4

Max tank operang temp. °C 85

Max tank operang pressure bar 6

Electric heang module

connecon inch 2” female 2 x 2”

female

2 x 2”

female 2” female 2” female

Weight kg 61 83 111 170 200

7. TECHNICAL DATA

6. RECYCLING AND DISPOSAL

According to the NIBE rules, the products have been manufac-

tured of high quality materials using the latest technologies

and soluons that do not endanger the environment.

When selecng materials, we took into account both the pos-

sibility of reuse of materials (recycling) that can be disassem-

bled and separated from materials unsuitable for recycling,

as well as risks arising from the processing of materials not

intended to reuse.

The purchased device consists in more than 90 % of parts that

can be recycled and reused, so they are safe for the environ-

ment and human health.

In order to prevent damage to piping systems and

environmental polluon, the product should only be

disassembled and taken out of service by appropriately

qualied specialists.

CAUTION

At end-of-life, take care that the product and all the

equipment were disposed of in accordance with appli-

cable regulaons.

CAUTION

The packaging, in which the product is delivered, is made

mainly of materials suitable for recycling and ulizaon.

Aer installaon, you should ensure the proper disposal

of packaging in accordance with applicable regulaons.

Informaon

Warnings:

• Never acvate circulaon of the heang medium unless

the buer tank is lled with the heang medium.

• Never operate the buer tank if you nd any malfuncon

in the safety valve operaon.

• Never install any device (such as cut-o and/or check

valves, etc.) between the tank and the safety valve or

open expansion tank (except T-pipes.)

• Any repairs of the buer tank by the user are forbidden.

• Stopping water leaks from the safety valve is not allowed.

Table 1. Technical data

• Limit the setpoints of the heang medium temperature

controllers in the buer tank supply lines to 85 °C.

• Check the operaon of the safety valve periodically as

described by the manufacturer of the valve in order to

check whether it is not clogged

• In order to eliminate any odour of hydrogen sulphide (caused

by bacteria in the oxygen decient water), we recommend

observing the periodic cleaning of the tank and replacement

of the anode and, in addion periodically increase the hot wa-

ter temperature in tank to prevent bacterial growth.

• Report any malfuncons in the buer tank operaon to

the authorized service centres. You can nd the complete

list of our authorized service centres

• Open the vent to vent the buer tank before the heang

season start.

• Check lling of the C/H system from me to me.

Praccal Recommendaons:

4.5 Warnings and Praccal Recommendaons

* Acc. to EU regulaons No. 812/2013 & 814/2013.

INSTALLATION AND OPERATING MANUAL

To prevent bacterial growth we recommend to make

sure a periodically increase of hot water temperature for

a shorter me at regular intervals e.g. every 14th day.

CAUTION