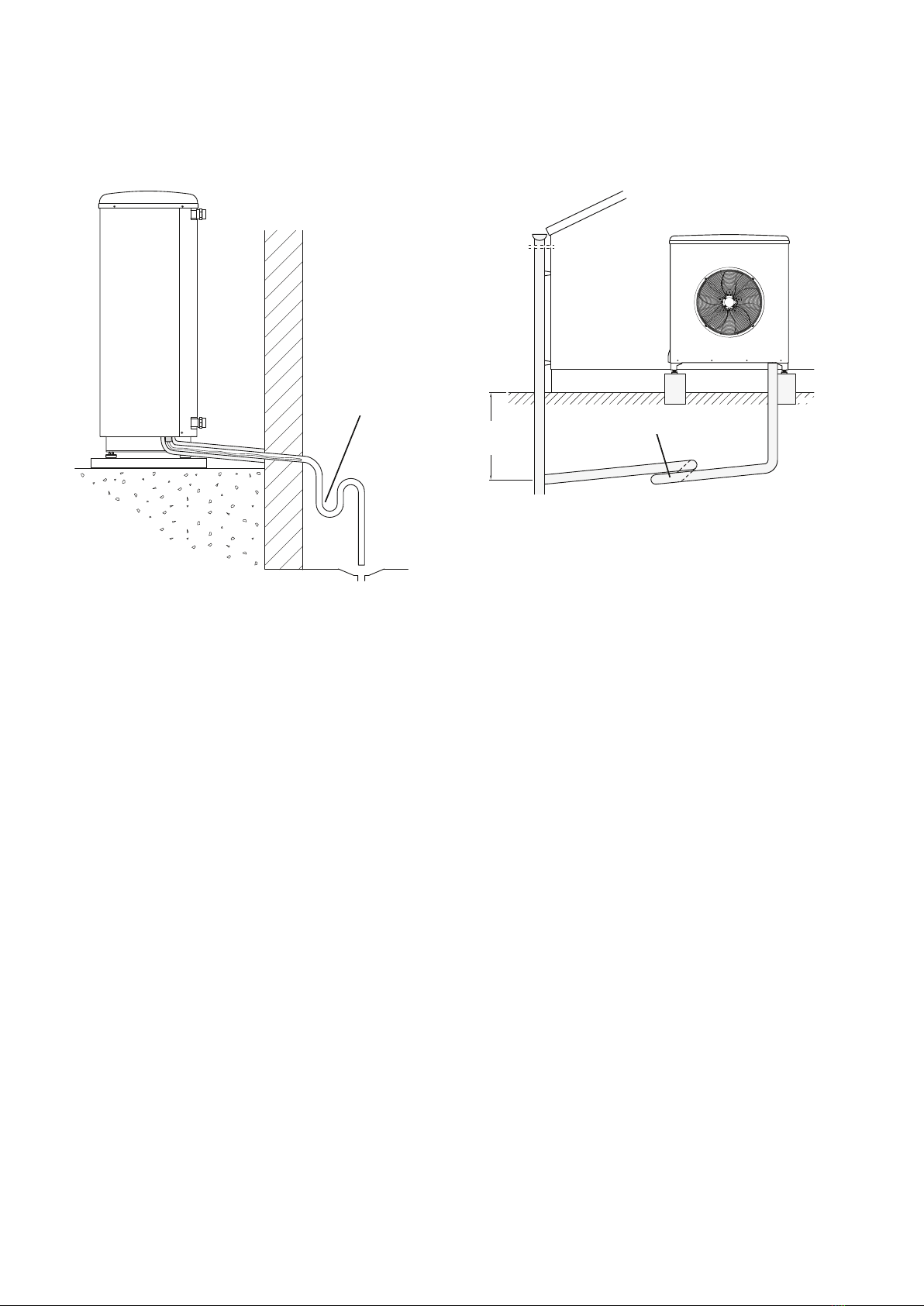

Condensation water trough

The condensation water trough is used to collect and

lead away most of the condensation water from AMB

30.

NOTE

It is important for the air collector module op-

eration that condensation water is led away

and that the drain for the condensation water

run off is not positioned so that it can cause

damage to the house.

NOTE

Pipe with heating cable for draining the con-

densation water trough are not included.

NOTE

The electrical installation and wiring must be

carried out under the supervision of an author-

ised electrician.

Caution

If none of the recommended alternatives is

used good lead off of condensation water

must be assured.

႑The condensation water (up to 100 litres/24 hrs)

collected in the trough should be routed via a pipe

to an appropriate drain, it is recommended that the

shortest outdoor stretch possible is used.

႑The section of the pipe that can be affected by frost

must be heated by the heating cable to prevent

freezing.

႑Route the pipe downward from AMB 30.

႑The outlet of the condensation water pipe must be

at a depth that is frost free or alternatively indoors

(with reservation for local ordinances and regula-

tions).

႑Use a water trap for installations where air circulation

may occur in the condensation water pipe.

႑Insulate the pipe (at least 19 mm of insulation) all

the way outside.

႑The insulation must be tight against the bottom of

the condensation water trough.

LEK

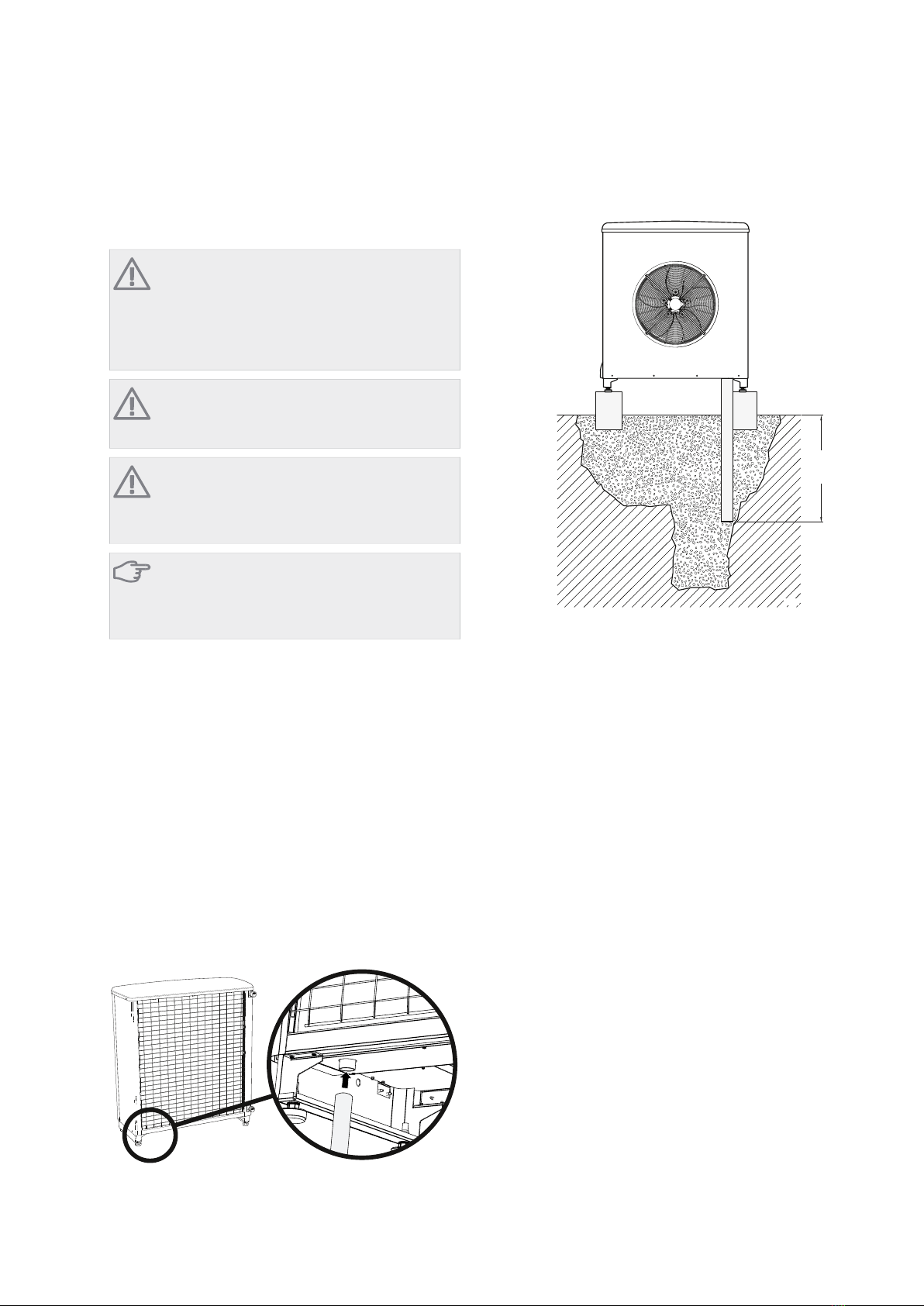

Fix the drainage hose to the connection under AMB

30 (recommended dimension 32 mm) with hose

clamps.

Recommended alternatives

Stone caisson

LEK

Frostfritt

djup

)URVW SURRI

GHSWK

If the house has a cellar the stone caisson must be po-

sitioned so that condensation water does not affect

the house. Otherwise the stone caisson can be posi-

tioned directly under the heat pump.

The outlet of the condensation water pipe must be at

frost free depth.

AMB 30Chapter 2 | Delivery and handling6