used, the scope of supply includes a central earthing

point that should be used for this purpose.

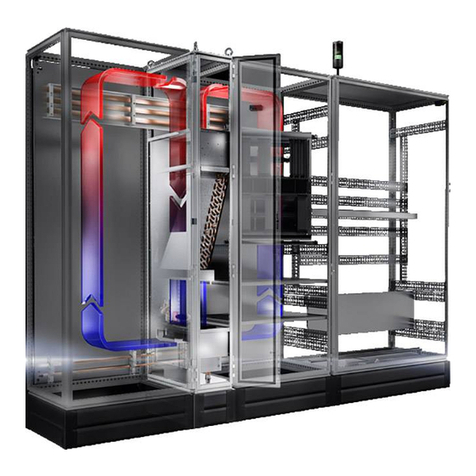

The split unit used for the cooling prevents dust and

corrosive combustion gases from entering the Micro

Data Centre. Several variants and power ranges

adapted to the heat loss and the customer conditions

can be chosen.

The CMC can optionally be used as network-compat-

ible monitoring system for monitoring the interior.

An early fire detection as well as fire alarm and extin-

guishing system can also be integrated as 482.6 mm

(19") components and offer a high degree of safety.

Various busbars adapted to the power distribution re-

quirements are available.

3.3

Standard system components

3.3.1

Cable duct

Note:

The connection of the cable ducts and also

expansions in a previously closed cable

duct may only be performed by authorised

service personnel otherwise the warranty

will be voided! If further lines or cables

should be inserted in a cable duct, the

manufacturer must be informed.

Soft duct

The soft duct consists of flexible material that can be

installed around the data and supply lines to be intro-

duced into the Micro Data Centre. The cables to be in-

troduced must be distributed separately to the individ-

ual positions. To ensure the guaranteed characteris-

tics against external danger potentials, no bundled

cables may be introduced into the Micro Data Centre.

After introduction of all cables, the complete area of

the cable duct is sealed externally and internally.

The soft duct has the dimension W x H 165 x 267 mm

and may be occupied with cables to the maximum

level of 60%.

The following cables and supply lines may be inserted

through the duct:

–

Copper / steel tubes to max. 18 mm diameter

(min. 1 mm wall thickness)

–

Cables to max. 15 mm diameter

When steel tubes are inserted, an additional cable

duct protection box must be placed in front of the soft

duct.

Cable box

The cable box for the introduction of data and supply

cables consists of a sheet steel enclosure lined on all

sides with alkaline-silicate blocks. In case of fire or

temperatures above 100°C, this material swells and

closes the cable opening. EN

On the face side, the cable box is closed smoke-tight

with plastic end caps. After the introduction of all ca-

bles and supply lines, the cable entrance must be

sprayed to become smoke tight.

The cable box is divided into two areas:

The dimension of each area is W x H: 214 x 33 mm

To permit the passage of larger connector plugs, the

centre bar can be removed but must be replaced be-

fore being sealed.

The cable box can beoccupied 100%.

The cable box may be occupied with cables with max-

imum 15 mm diameter. The cable box may be occu-

pied with 3311.040 water supply and return hoses for

the LCP. No steel tubes may be fed through the cable

box.

Hard duct

To guarantee large manipulation assurance in the ca-

ble duct area, a hard duct can be deployed optionally.

Each cable is laid with a filler piece matched to the ca-

ble diameter. An end seal ensures the pressing-in of

the complete system.

For stabilisation, the duct system is inserted in a con-

struction frame that absorbs the pressure.

The following cables and supply lines may be inserted

through the duct:

–

Copper / steel tubes to max. 18 mm diameter

(min. 1 mm wall thickness)

–

Cables to max. 15 mm diameter

When copper or steel tubes are inserted, an

additional cable duct protection box must be placed in

front of the soft duct and the tubes have to be

insulated with ArmaFlex Protect outside of the Micro

Data Center.

3.4

Proper use, foreseeable misuse

The unit may be used only for the acceptance of IT

components while also providing protection against

dangers, such as fire, water or unauthorised access.

Any other use is not permitted.

The unit is state of the art and built according to rec-

ognised safety regulations. Nevertheless, improper

use can present a hazard to life and limb of the user

or third parties, or result in possible damage to the

system and other property.

Consequently, the unit must only be used properly

and in a technically sound condition! Any malfunc-

tions which impair safety should be rectified immedi-

ately! Observe the operating instructions!

The intended use also includes the observance of the

provided documentation and fulfilling the inspection

and maintenance conditions.