8 of 48 Jan 2011 2010-8405 Rev E

per ISO 8359 Standard

Concentration: 2 liters per minute at >90%

5 liters per minute at 90% (+ 6.5 / - 3%)

(Based on 21°C [70°F] at sea level)

Response Time: Acceptable concentration is normally achieved in about 90 seconds;

allow 5 minutes to attain full concentration.

Positioning: Operate the unit in an upright position, maintaining at

least six inches of open space on all sides for ventilation.

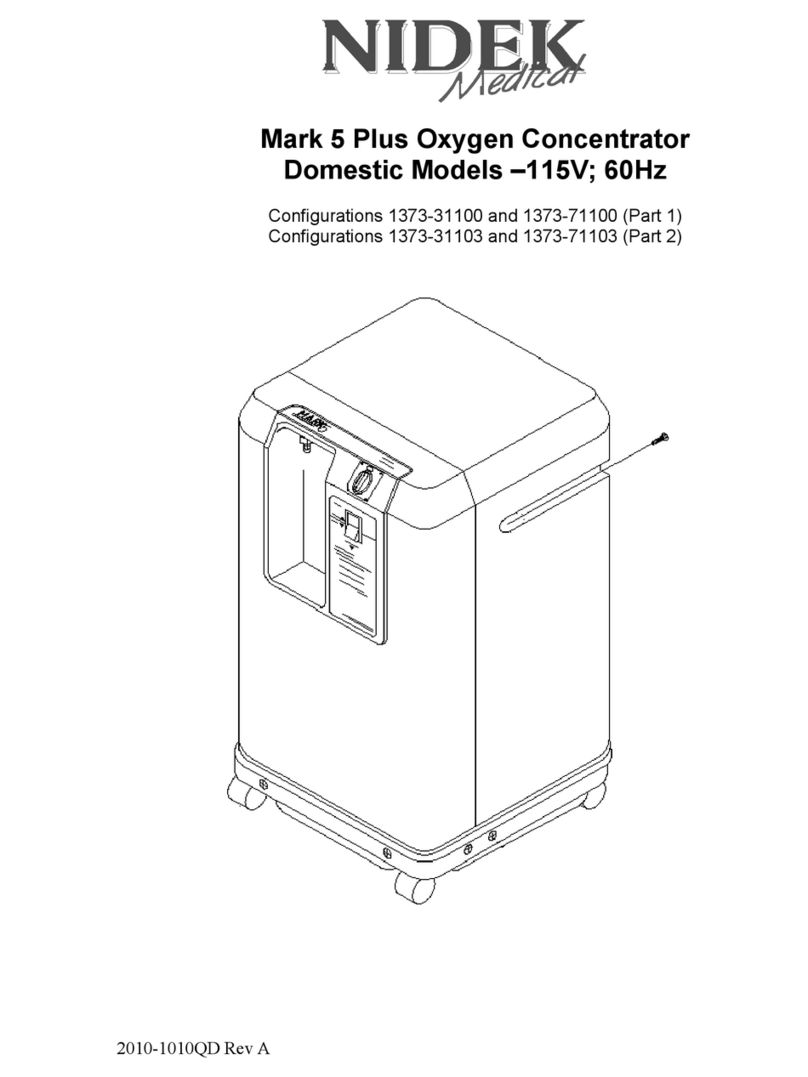

2.0 Operational Check and Concentration Test

2.1 Description of Operation

Air enters the MARK 5 NUVOLite Oxygen Concentrator through an external cabinet air filter. This

filtered air enters the compressor via a suction tube and fine filter, which quiets the suction sounds

made by the compressor. Pressurized air then exits the compressor and passes through a heat

exchanger into a pair of 3-way solenoid valves. The heat exchanger reduces the temperature of the

compressed air. Next, the solenoid valve directs the air into one of two sieve beds that contain

molecular sieve. The special characteristic property of molecular sieve is that it physically attracts

(adsorbs) nitrogen when air passes through this material, thus enabling the production of high purity

oxygen.

There are two sieve beds or adsorbent columns; while one produces high purity oxygen, the other is

purged of the nitrogen it adsorbed (collected) while it was producing oxygen. Each column produces

oxygen for approximately five seconds and delivers it to the product storage volume tank integrated

into the sieve module. Oxygen exits the product storage tank through a pressure regulator, flow

control valve, and final product filter. The flow control valve, controls the flow rate of oxygen delivered

to the patient. The MARK 5 NUVOLite unit delivers up to 95% oxygen concentration at flow rates

from 0.125 to 5 l/min. The remaining constituents of the product gas stream are nitrogen and argon,

both of which are part of the air we breathe, are inert and are completely safe.

2.2 Operational Check

Nidek Medical runs each device through a burn in period and tests every MARK 5 NUVOLite

Oxygen Concentrator thoroughly after manufacture before releasing for shipment. As the home

service provider, it is your responsibility to perform the following test to ensure that no damage

occurred in shipping or handling.

1. Open and inspect all concentrator cartons upon receipt. Unpack each unit and remove it from

its carton. Inspect the unit itself for damage. If the exterior of the carton is damaged, or the

unit itself is damaged, note it on the freight bill signed by the driver.

2. Plug in the power cord of the unit, and set the I/0 (ON/OFF) switch to the I (ON) position.

Check to see that the following occurs:

● The compressor runs, listen for the sound.

● Exhausted cooling air flows out of the bottom rear of the unit.