7.25 Front Stopper Switch ........................................................................................... 7-14

7.26 P.S. Board............................................................................................................ 7-15

7.27 BA05 Replacement Unit for EMC ........................................................................ 7-17

7.28 Fixing Knob.......................................................................................................... 7-19

§8 ADJUSTMENT.................................................................................8-1

8.1 Setting Time and Date ............................................................................................. 8-1

8.2 Adjusting Camera Position ...................................................................................... 8-1

8.3 Adjusting Video Signal Level ................................................................................... 8-2

8.4 Adjusting Camera Focus ......................................................................................... 8-2

8.5 Adjusting Focus and Position of Optical Reticle...................................................... 8-3

8.6 Adjusting AL2 LED Optical Axis ............................................................................... 8-4

8.7 Adjusting Optical Axis of Applanation Detector........................................................ 8-5

8.8 Electric Adjustment .................................................................................................. 8-6

8.8.1 Adjusting AL2 LED offset voltage................................................................... 8-6

8.8.2 Adjusting comparison voltage ........................................................................ 8-6

8.8.3 Adjusting AL1 LED light amount..................................................................... 8-7

8.9 Adjusting Reference Marker Position ...................................................................... 8-8

8.10 Adjusting PSD Balance.......................................................................................... 8-9

8.11 Adjusting Fixation Lamp Position......................................................................... 8-10

8.12 Adjusting Pressure of Puffed Out Air ....................................................................8-11

8.13 Adjusting Solenoid Brake..................................................................................... 8-12

8.14 Adjusting Front Cover LED Light ......................................................................... 8-13

8.15 Adjusting Applanation Detector ........................................................................... 8-14

8.16 Adjusting Camera Position (Second time)........................................................... 8-15

8.17 Adjusting Reference Marker Position (Second time)........................................... 8-15

8.18 Electric Adjustment (Second time) ...................................................................... 8-15

8.19 Adjusting PSD Balance (Second time) ............................................................... 8-15

8.20 Checking AL2 LED Adjustment............................................................................ 8-16

8.21 Adjusting Electronic Reticle Position ................................................................... 8-17

8.22 Checking OPEN THE EYE WIDER ..................................................................... 8-18

8.23 Checking Successive Air Puffing ......................................................................... 8-18

8.24 Adjusting Three-Point Tightening of Up/Down Movement Bearing ..................... 8-19

8.25 Adjusting Up/Down Movement of Measuring Unit ............................................... 8-20

8.25.1 Tighteness of nut holder............................................................................. 8-20

8.25.2 Feed screw holder for up/down movement................................................ 8-20

8.26 Adjusting Chinrest Up/Down Movement.............................................................. 8-21

8.27 Adjusting Pulse Wave .......................................................................................... 8-21

8.28 Adjusting A Constant and B Constant.................................................................. 8-22

8.29 Checking Measuring Unit Position ...................................................................... 8-23

8.30 Measuring Model Eye.......................................................................................... 8-24

8.30.1 Electric model eye...................................................................................... 8-24

8.30.2 Silicone model eye..................................................................................... 8-24

§9 SUPPLEMENT.................................................................................9-1

9.1 Wiring Diagram........................................................................................................ 9-1

9.2 Error Message ......................................................................................................... 9-2

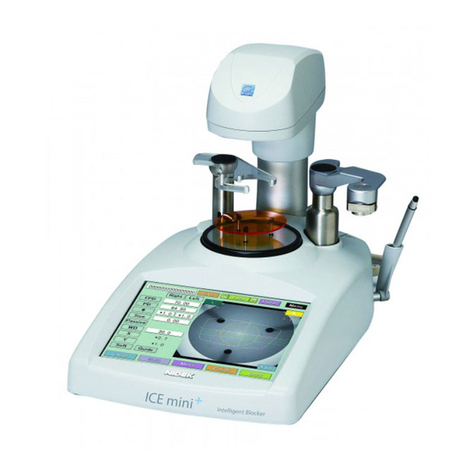

9.3 External View........................................................................................................... 9-3