Nidek Medical Lex 1000 Guide

Other Nidek Medical Medical Equipment manuals

Nidek Medical

Nidek Medical NT-2000 User manual

Nidek Medical

Nidek Medical RT-5100 User manual

Nidek Medical

Nidek Medical ARK-730A User manual

Nidek Medical

Nidek Medical ConfoScan4 User manual

Nidek Medical

Nidek Medical AR-600 User manual

Nidek Medical

Nidek Medical LT-980 User manual

Nidek Medical

Nidek Medical NT-510 User manual

Nidek Medical

Nidek Medical Max 30 3005 User manual

Nidek Medical

Nidek Medical Mark 5 Nuvo Lite Series User manual

Nidek Medical

Nidek Medical Nano User manual

Nidek Medical

Nidek Medical Mark 5 Nuvo MB User manual

Nidek Medical

Nidek Medical AR-360A User manual

Nidek Medical

Nidek Medical RT-3100 User manual

Nidek Medical

Nidek Medical ARK-700 Series User manual

Nidek Medical

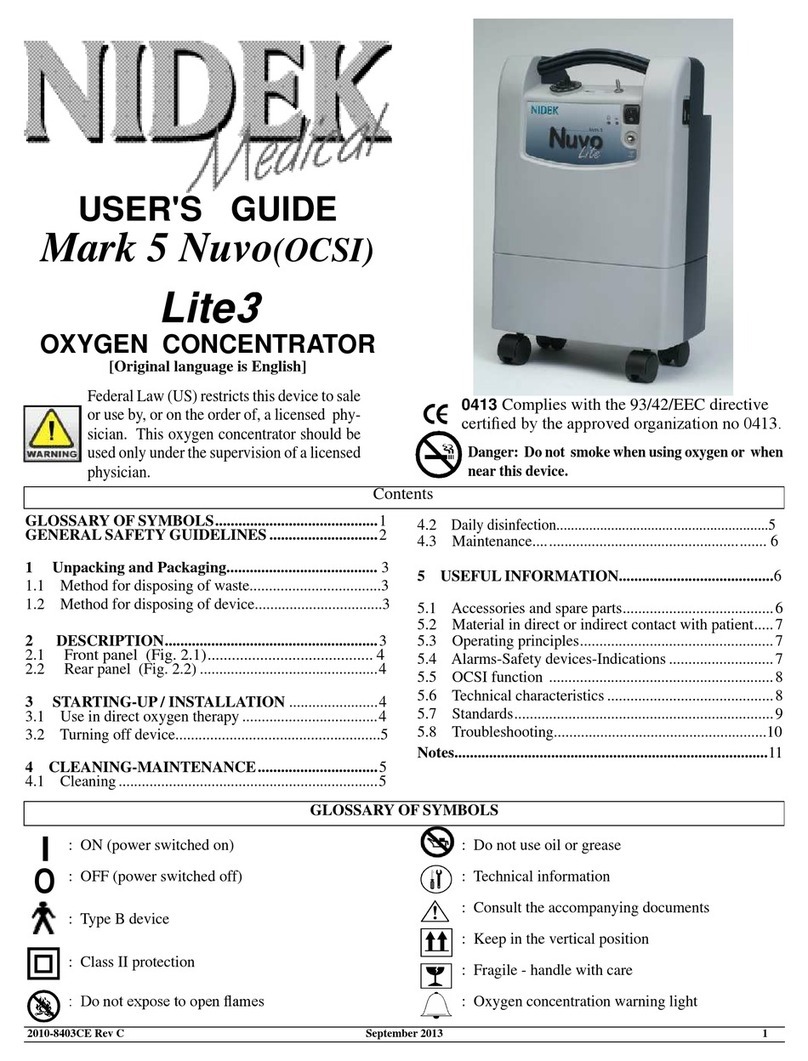

Nidek Medical Mark 5 Nuvo OCSI Lite 3 User manual

Nidek Medical

Nidek Medical GYC-1000 User manual

Nidek Medical

Nidek Medical TONOREF II Manual

Nidek Medical

Nidek Medical RT-3100 User manual

Nidek Medical

Nidek Medical Mark 5 Nuvo Lite Family User manual

Nidek Medical

Nidek Medical Mark 5 Nuvo Lite User manual