9/99__________________________________________________________Sect 1 Pg3

Principles of Operation

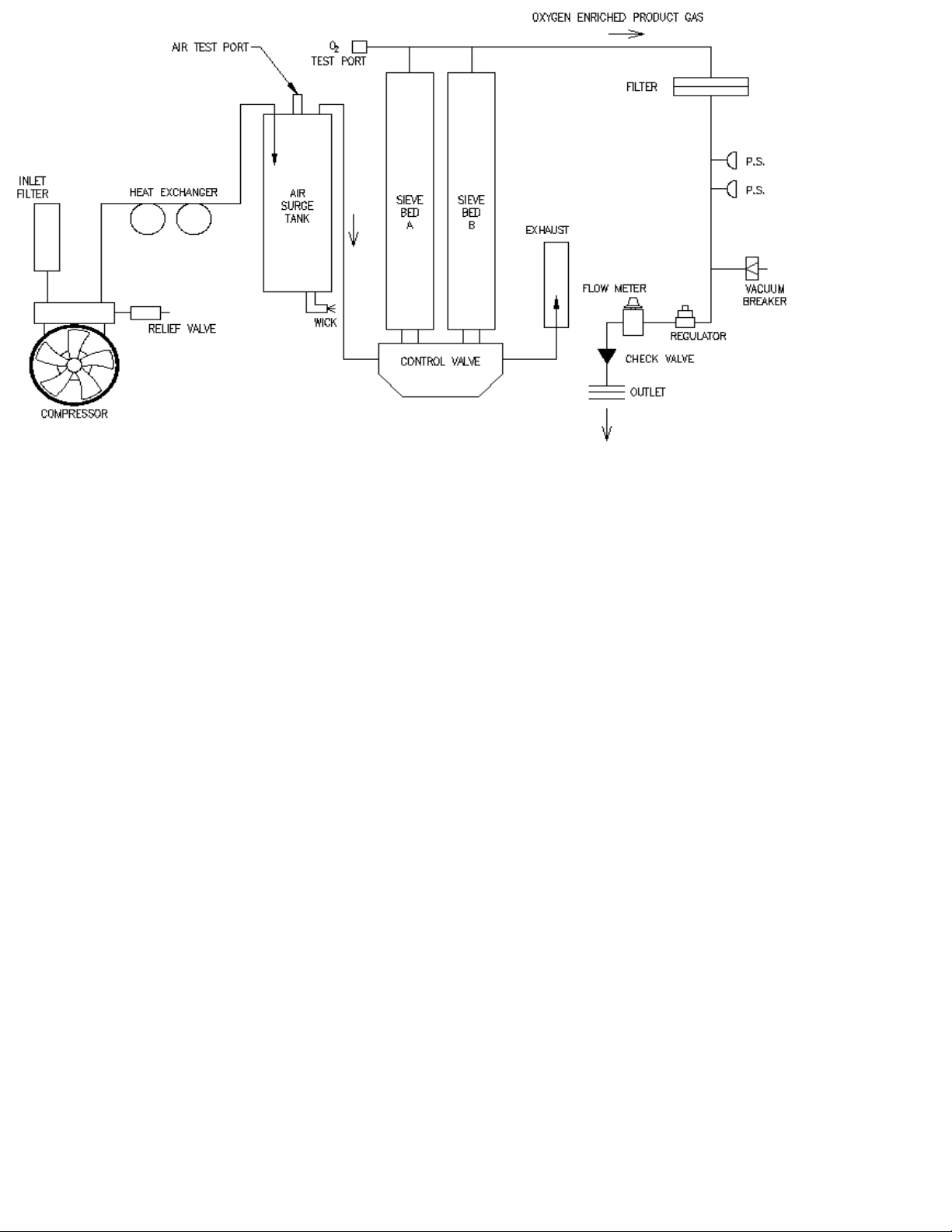

The Mark 5 Plus Concentrator takes in room air that contains 21% oxygen, 78%

nitrogen and trace amounts of inert gases. The air is filtered, compressed and passed

through one of the two molecular sieve beds which allows the oxygen to pass but traps

most of the nitrogen. Before the nitrogen saturates the molecular sieve in the first bed it is

vented to the atmosphere and purged with oxygen while air is fed to the second bed. This

process of alternate feeding and venting of beds is continued thus producing oxygen

enriched gas at one end and exhaust at the other end of the sieve beds. The oxygen

produced is then filtered, regulated, and set at a given flow rate for delivery to the patient.

The operation of the Mark 5 Plus can be grouped into three distinct systems; the

compressed air system, the process system and the delivery system.

Compressed Air System

Air enters the system through filters which prevent dust and other particles from

entering and potentially damaging the air compressor. The compressor is a reciprocating

two cylinder positive displacement type that compresses the air to the necessary pressure.

The compressed air is then routed through a heat exchanger to reduce its temperature and

then to the air surge tank. The surge tank reduces air pressure swing and traps moisture.

The wick assembly, located at the bottom of the surge tank, allows the moisture to be

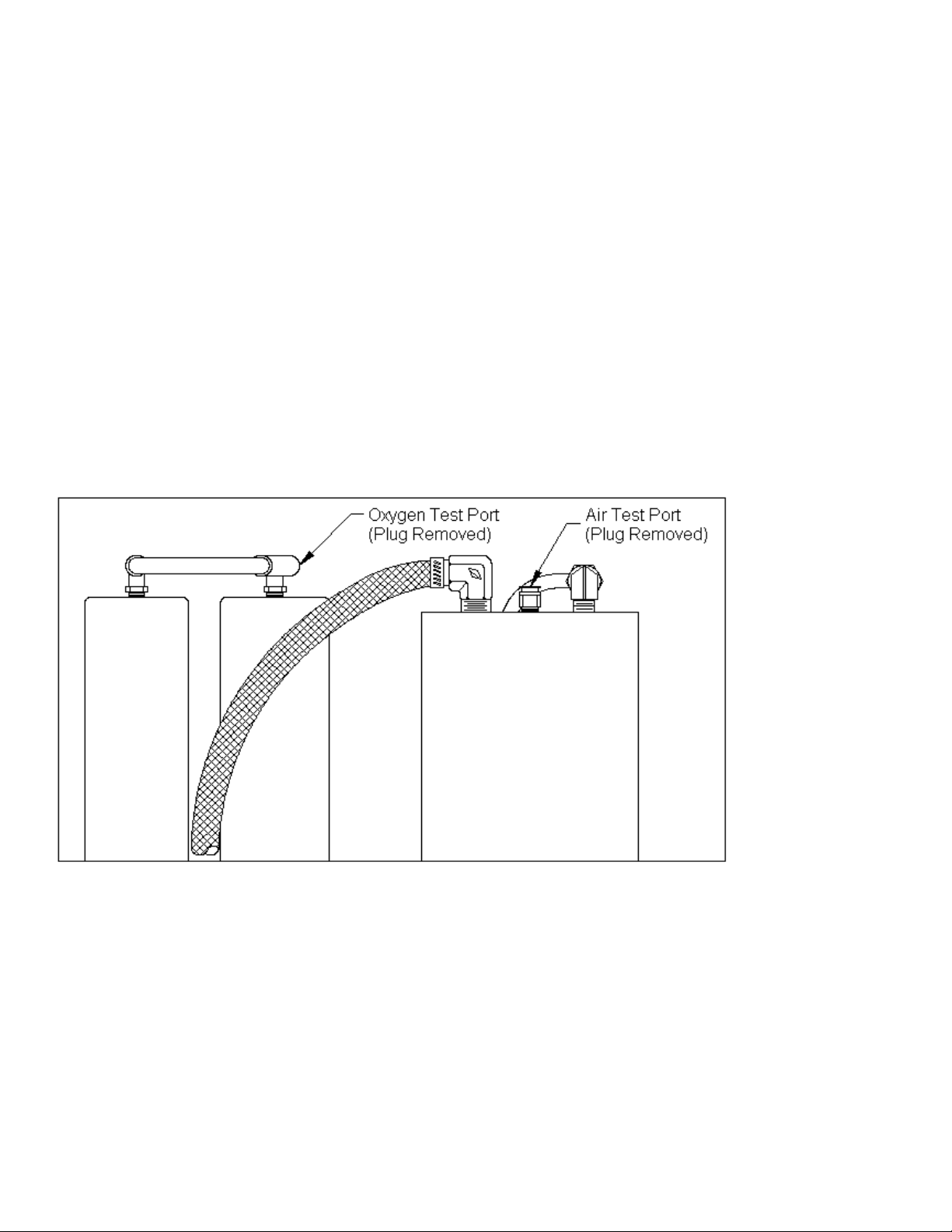

evaporated to atmosphere. The system also has a safety relief valve to prevent pressure

buildup should a blockage occur and a test port for measuring system pressure.

Process System

The process system consist of two sieve beds and a rotary poppet valve. The valve

controls the process by alternately feeding air into and exhausting nitrogen from the sieve

beds. The valve utilizes a gear motor to cause a cam action to alternately open and close

feed and exhaust poppets. Thus, what normally is a complex control system in other

concentrators is reduced to a simple and easily understandable mechanical control in the

Mark 5 Plus.

Delivery System

The cyclic process described above causes pressure variations in the oxygen as it

exits the beds. In order to provide a stable flow, the oxygen, after passing through a

bacterial filter to remove any contaminants, is passed through a regulator to establish a

fixed delivery pressure. A flow control valve consisting of multiple orifices then establishes

a fixed flow rate to the patient. The use of a vacuum relief breaker and check valve in this

section prevents the possibility of contaminants entering the system from the outside. Two

pressure switches monitor the oxygen pressure and cause an alarm to sound if the

pressure is high or low. An Oxygen Monitoring System for continuously monitoring oxygen

purity is available as an option. The operation of the Oxygen Monitoring System is

described separately in Section ➋.