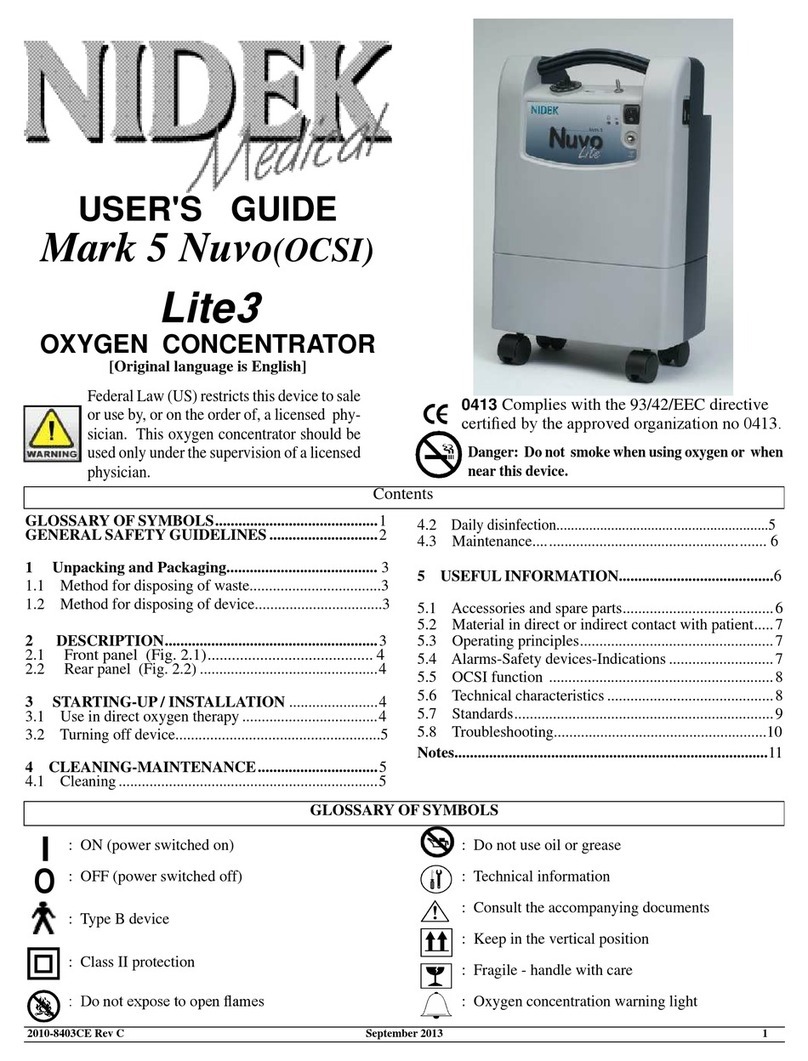

2010-2225 Rev - B Page 9 of 59

Do not use any oil or grease on or near the device

1.3 Functional Specifications

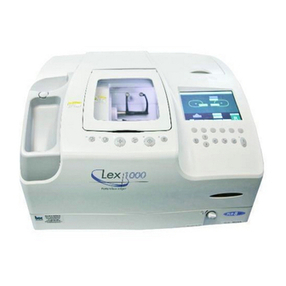

Dimensions: 15.5 in. long, 15.6 in. wide, 27.8 in. tall

(394 mm long, 396 mm wide, 706 mm high)

Weight: 50 to 54 Ib (22.5 to 24.5 kg) depending on sound attenuation;

Electrical 120 VAC, 60 Hz, 4 amps, 410 watts

Requirements: 220 VAC, 50 Hz, 2 amps, 420 watts

Capacity: 5 liters per minute at 90% oxygen

(Based on 70°F [21°C] at sea level)

Accuracy: Flow meter ±5% full scale. (Based on pre-calibrated analysis.)

Concentration: 1 - 3 liters per minute at 95% + 0.5 / - 3%

4 liters per minute at 92% + 3.5 / - 3%

5 liters per minute at 90% + 5.5 / - 3%

Response Time: Acceptable concentration is normally achieved in about

90 seconds; allow 5 minutes to attain full concentration.

Positioning: Operate the unit in an upright position, maintaining at

least six inches of open space on all sides for ventilation.

2.0 Operational Check and Concentration Test

2.1 Description of Operation

Air enters the Mark5 Nuvo® Oxygen Concentrator through an external cooling air

intake filter. This filtered air enters the compressor via a suction resonator and fine

filter, which quiets the suction sounds made by the compressor. Pressurized air

then exits the compressor and passes through a heat exchanger into an air tank.

The heat exchanger reduces the temperature of the compressed air and the air tank

stores air when feed is interrupted. Next, a rotary poppet feed valve directs the air

into one of two sieve beds that contain molecular sieve. The special characteristic

property of molecular sieve is that it physically attracts (adsorbs) nitrogen when air

passes through this material, thus enabling the production of high purity oxygen.

There are two sieve beds or adsorbent columns; while one produces high purity

oxygen, the other is purged of the nitrogen it adsorbed (collected) while it was

producing oxygen. Each column produces oxygen for approximately four seconds

and delivers it to the product storage volume in the end of the column. Oxygen exits

the adsorbent column through a pressure regulator, flow control valve, flow meter,

and final product filter. The flow control valve, which is part of the flow meter,

controls the flow rate of oxygen delivered to the patient. The Mark5 Nuvo® unit