Niigata Seiki Co., Ltd.

5-3-14, Tsukanome, Sanjo, Niigata, Japan, 955-0055

Tel. : +81-256-33-5522 Fax. : +81-256-33-5518

MAIL intl.sales@niigataseiki.co.jp

URL http://www.niigataseiki.co.jp

Adjacent error

DIGITAL BORE GAUGE

Model No.:WCDI-10D/WCDI-18D

<

combined

>

【Accessories】*Including supplied Digital Gauge

※Not including quantization error (±1 count)

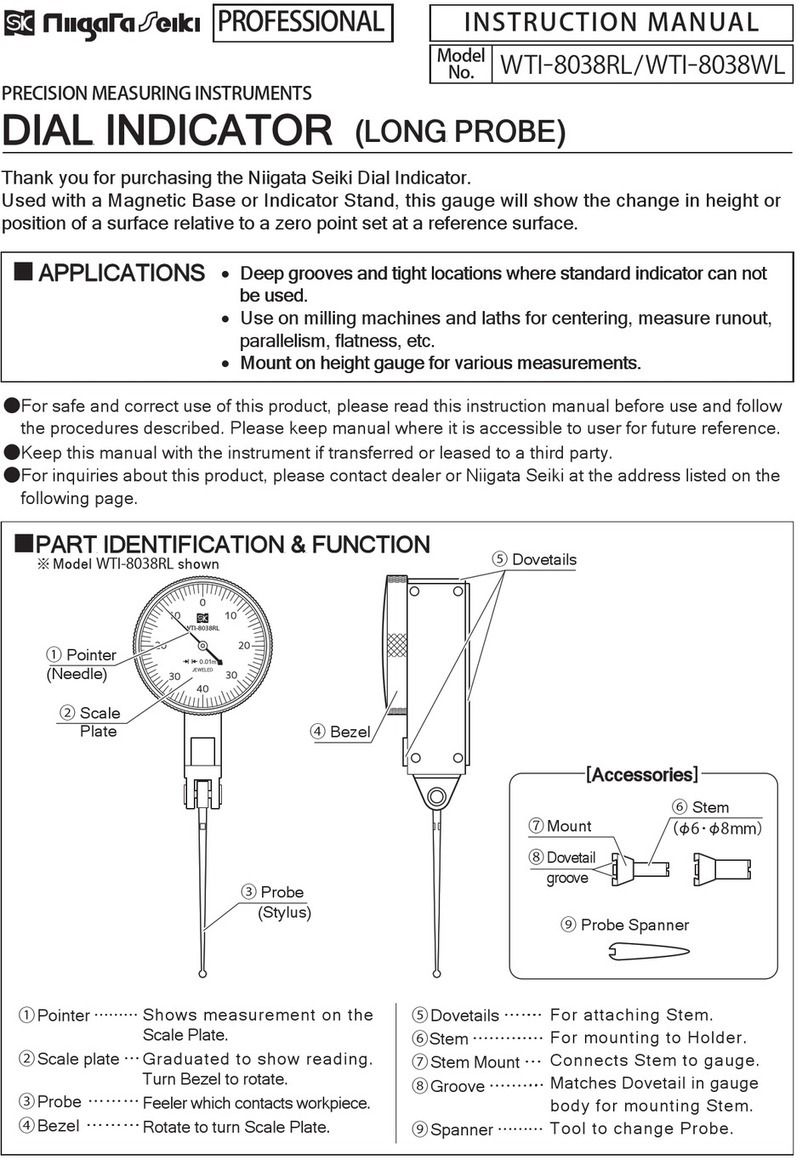

①Loosen the Clamp Screw and insert

the Digital Indicator into the gauge

body. Tighten the Clamp Screw to

secure.

※After attaching, press the [ZERO/ON]

Button on the Digital Indicator to turn on

power. Confirm that the displayed

reading changes by gently squeezing the

measurement head. If necessary, adjust

the depth that the Digital Indicator is

inserted into the gauge body.

②Select the Extension Rod, washer (WCDI-18Donly)for the desired

measurement range.

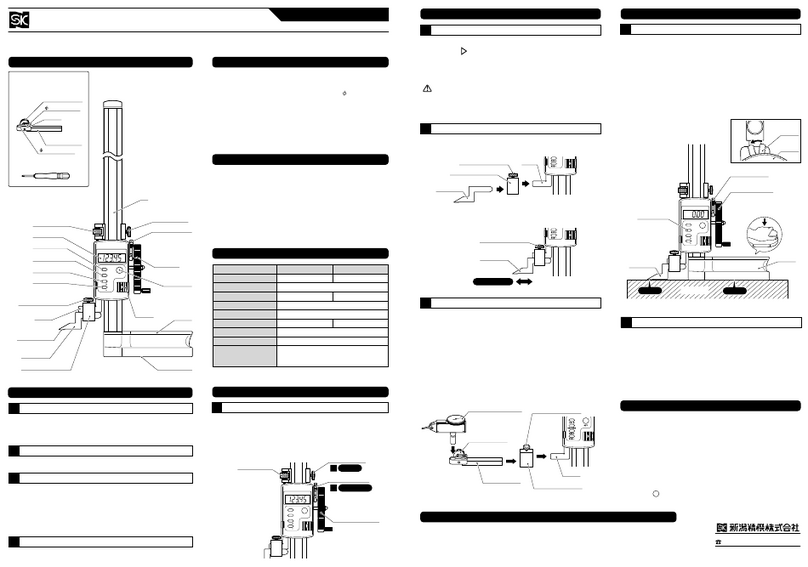

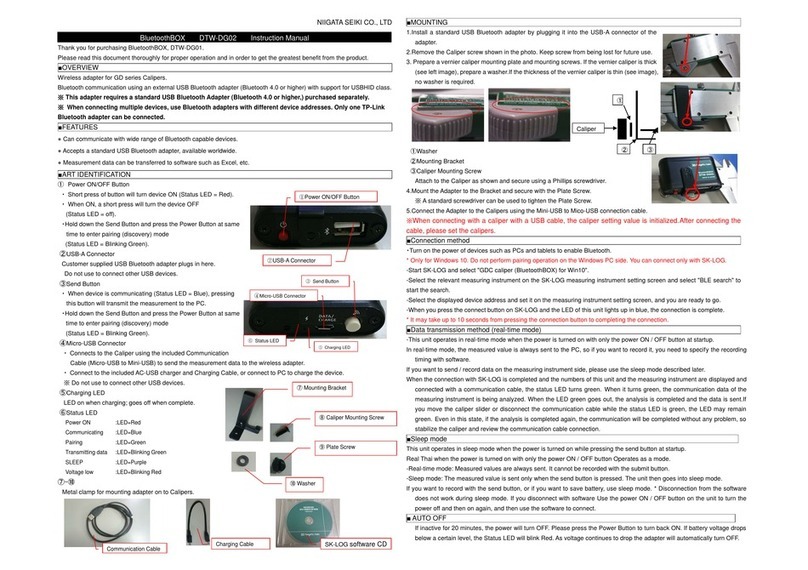

■PART IDENTIFICATION

WCDI

-

10D

6

-

10

12

5

0.7

WCDI

-

18D

10

-

18

0 . 0 0 2

3

12

5

0 . 0 0 2

3

0.9

0〜6.0

【WCDI-18D】【WCDI-10D】Spanner

Spanner

Nut

1. Use the Spanner to loosen the

Nut at the bottom of

Measurement Head.

2. Install the Extension Rod and

tighten.

Attach the Extension Rod,

Washer to the bottom of the

Measurement Head and tighten

with the Spanner.

Ex. Rod

8.5mm +Washer 0.5mm

(WCDI-18D only)Extension Rod

(WCDI-10D)(WCDI-18D)Spanner

(WCDI-10D)(WCDI-18D)NOTICE

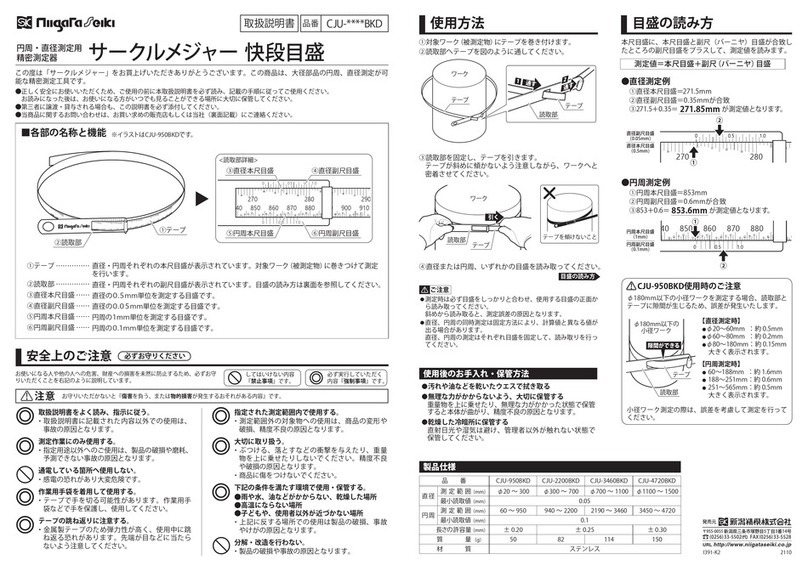

■INSERTING・REPLACING BATTERY

■AUTO OFF DELAY

Use only CR2032 type lithiumbutton cell.

NOTICE

Auto Off Delay

2 6 5 3 0 0

**※※*※①Press and hold the [ZERO/ON]Button to turn power OFF.

②Press and hold [ABS/SET]and [ZERO/ON]Buttons at the

same time.

③When「-----」is displayed, ❶release the [ZERO/ON]Button,

❷then release the [ABS/SET]Button in that sequence.

④The Auto Off Delay time will be displayed. Press [ABS/SET]

to change.

※Each press of the [ABS/SET]Button will change the delay

by 1/2 hr. (30 min.)from 0 to 6 hr.

⑤Press [ZERO/ON]when done and display will return to the

measurement screen.

※Once set, the delay time is saved even when power is OFF.

Thank you for purchasing the Digital Bore Gauge.

Please read this manual thoroughly before use for proper operation.

Instruction Manual

●This is a precision instrument, handle with care.

●Do not disassemble or modify.

●Keep instrument away from water and oil.

●Use only with supplied Extension Rods and Washer.

●Keep instrument away from direct sunlight and high temperatures

such as in a car, or near a stove or heat source.

●After use, remove any dirt or cutting chips and apply rust

preventative oil to Extension Rod and Washer. When not in use

store in supplied storage case.

●This product is for measuring inside diameter; use only as directed.

Improper use may cause accident or injury.

●Avoid using in high electric fields, such as near fluorescent lights or

switching power supplies. Electrical interference may cause

incorrect readings.

Pull out the case from the two

side edges to remove. Insert

battery with

(

+

)

side facing

down.

Battery

Case

Battery

(CR2032)※1:Not Used

※2:"0.01" indicates the resolution of

the display's digital bar graph.

The bar graph display will

change with each 0.01mm change in the measured value.

※Spanners shown in drawing

above vary slightly in

appearance, but function will

be same.

Ex.)

WCDI-10D set to 8.5mm

Ex.)

WCDI-18D set to 14.5mm

Length below Handle:

100mm

Extension

Rod

Measurement

Head Guide

Probe

Tip

Probe

Tip

[ZERO/ON]

Button

[CAL]Button

Handle

Cap

Length below

Handle:

※1※2

[MIN]Button

[ABS/SET]

Button

Clamp

Screw

Gauge

(Digital Indicator)

LCD Display

Extension

Rod

Measurement

Head

50mm

(μm)(mm)(mm)(μm)(μm)(mm)(g)Measuring Range

Resolution

Wide range accuracy

Repeatability

Single Stroke Range

Weight

Model No. (hr)●Extension Rods

WCDI

-

10D ・・・・6・6.5・7・7.5・8・8.5・9・9.5・10mm(9 pieces) WCDI

-

18D ・・・・10・11・12・13・14・15・16・17・18mm(9 pieces)●Washer ・・・・・・・0.5mm(WCDI-18D only)●Spanner ・・・・・・1x

●Battery ・・・・・・・CR2032 Lithium button cell, 1x(for test)Ex. Rod

14mm

Washer

0.5mm

Clamp

Screw

INSERT

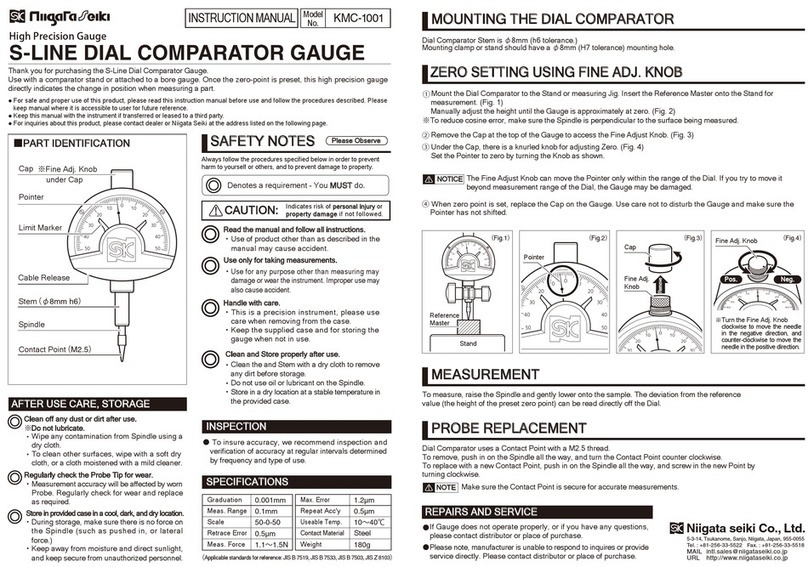

Shaft (Fig.1)(Fig.2)(Fig.3)(Fig.4)(Fig.5)(Fig.6)For accurate measurements, follow the procedure described below.

①In cross section perpendicular to the axis of the bore, as shown in Figure 1, position the gauge along diameter ⓐ. This is the

maximum distance, and at this point the Indicator will read the maximum value. The Guide will automatically position the Measurement

Head to diameter ⓐwhen inserted.

※WCDI-10D does not have a guide on the Measurement Head so please manually position at this maximum value.

②In cross section parallel to the axis of the bore through diameter ⓐ, position the indicator to minimize the distance ⓑ. (Figure 2)

In this position the Indicator will read the minimum value. This position must be manually determined by pivoting the Gauge as shown

in Figure 3 while watching the Indicator to find the minimum value.

①Before use, please make sure the Measurement Head components are not loose and tighten if necessary.

②Clean the Measurement Head and the ID of a Ring Gauge Standard using parts cleaner or cleaning solution.

③Press the [ZERO/ON]Button to turn on power. ※A long press to the [ZERO/ON]Button will turn power off.

①Turn on power. If “”or “”symbols are displayed on the LCD,

press the [MIN]Button to turn off. If “ABS”is displayed press the

[ABS/SET]Button to turn off.

②Insert the Measurement Head into the Ring Gauge Standard and press

[MIN]Button to put the Indicator into minimum-mode. Slowly pivot the

gauge (Figure 3)to display the minimum value.

③Remove the gauge from the Ring Gauge and press the [CAL]Button until

“OK”is displayed.

Preparation for measurement is now complete.

④Put the gauge into the workpiece to be measured, and pivot the gauge

slowly. (Figure 3)The LCD will display the difference between the

measured workpiece and the calibration standard. (Figure 6)

※Press the [ON/ZERO]Button momentarily to reset display in preparation

to measure the next workpiece.

①Turn on power. If the “”or “”symbols are displayed on the LCD, press the [MIN]Button to turn off.

②Adjust the “SET”value of the Bore Gauge to match the ID of the Ring Gauge Standard. Press and hold the [ABS/SET]Button until

“SET”blinks on the display.

③Continue holding the [ABS/SET]Button and the display character to the left will blink. Use a short press of the [ABS/SET]Button to

change the value, and a long press to change the character being modified. Repeat this process to enter the dimension of the Ring

Gauge Standard on the LCD display. (Figure 4)

④When the value is entered the flashing position will return to “SET”. A short

press of the [ABS/SET]Button to turn off the flashing.

⑤Insert the Measurement Head into the Ring Gauge Standard and press the

[MIN]Button to put the Indicator into minimum-mode. Slowly pivot the

gauge (Figure 3)to display the minimum value.

⑥Remove the gauge from the Ring Gauge and press the [CAL]Button until

“OK”is displayed.

Preparation for measurement is now complete.

⑦Put the gauge into the workpiece to be measured, and pivot the gauge

slowly. (Figure 3)The LCD will display the measured value. (Figure 5)

※Press the [ON/ZERO]Button momentarily to reset display in preparation

to measure the next workpiece.

※Difference between workpiece and reference

COMPARATIVE MEASUREMENTS

ERROR CORRECTIVE ACTION ※If problem persists, or if you have any

questions, please contact distributor.

※Please note, manufacturer is unable to

respond to inquires or provide service

directly. Please contact distributor.

●LCD does not display

●Displayed value is unstable

●Display is not clear ●Cycle power by removing and

replacing battery.

●Replace battery with new one.

Work-

piece

Work-

piece

Diff. between Work-

piece and Reference

Set to match

Workpiece I.D. value

Ring Gauge

Standard