OFF

ON/ZERO

HOLD

ADD

SUB

OFF

ON/ZERO

HOLD

ADD

SUB

OFF

ON/ZERO

HOLD

ADD

SUB

OFF

ON/ZERO

HOLD

ADD

SUB

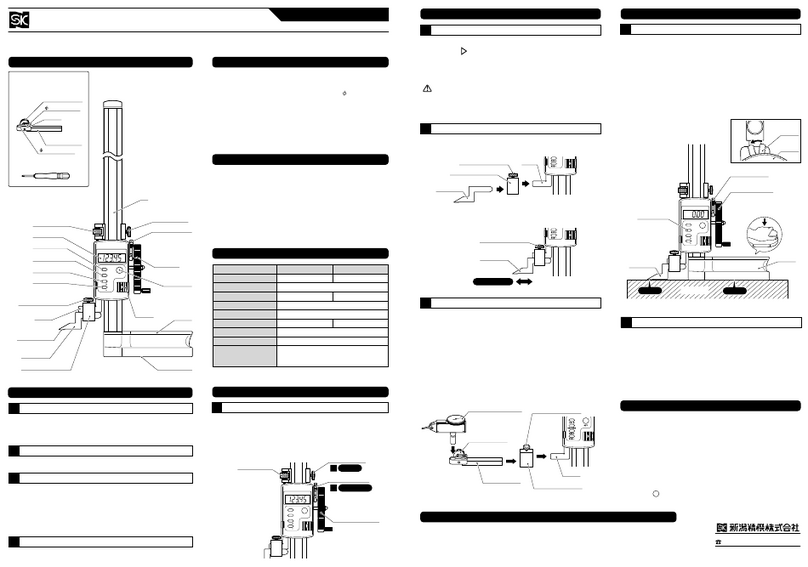

90° 90°

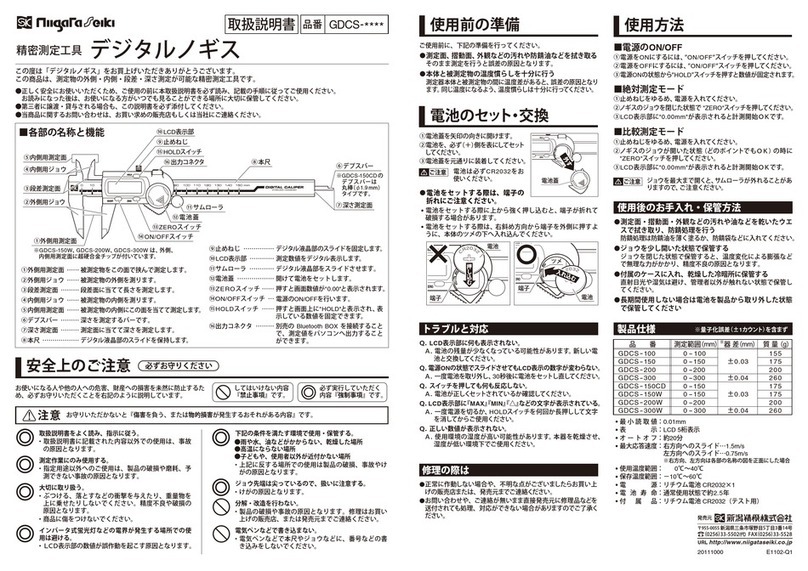

Example using dial indicator with measurement

read off the Height Gauge LCD display.

Scribe

Scribe Clamp Screw

Scribe Clamp Screw

Scribe

Scribe Clamp

Jaw

Jaw

Scribe Clamp

Scribe Clamp

Screw

Indicator Mounting Arm

1Example with measurement read off the Dial

Indicator and LCD display of the Height Gauge.

2

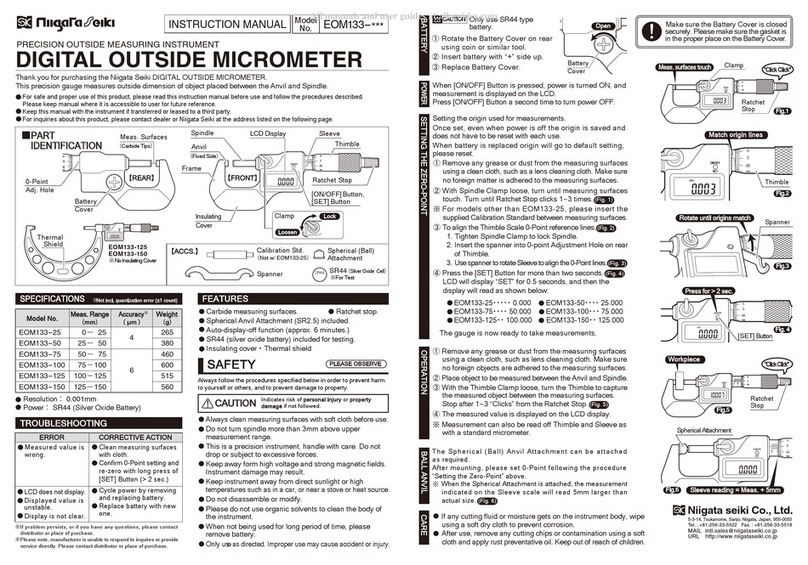

INSTRUMENT ERROR WHEN USING ACCESSORY DIAL INDICATOR (WTI-8038S)

To measure the height from reference surface:

①Place the Indicator Stylus on the reference surface, and set

the Indicator to 0.00mm.

②Set the Height Gauge reading to 0.00mm. This is the

reference position.

③Measuring Height.

Reposition the Dial Indicator Stylus to the surface to be

measured, and adjust the Height Gauge so that the Dial

Indicator reading is 0.00mm.

④The LCD display of the Height Gauge now shows the height

relative to the reference surface.

For this method, the total error is the sum of the Height

Gauge Instrument Error (VHS-30D : ±0.04mm,

VHS-60D : ±0.05mm)+Dial Indicator repeatability

(0.003mm)

To measure the height from reference surface:

①Place the Indicator Stylus on the reference surface, and set

the Indicator to 0.00mm.

②Set the Height Gauge reading to 0.00mm. This is the

reference position.

③Measuring Height.

Reposition the Dial Indicator Stylus to the surface to be

measured, and read the LCD display of the Height Gauge.

This value is 10.51mm

④Read the scale of the Dial Indicator.This value is +0.10mm

⑤The height relative to the reference surface is the sum, 10.51

+0.10=10.61mm

Make sure the sign (+, −)of the measurement

from the Dial Indicator is same as sign for the

Height Gauge.

For this method, the total error is the sum of the Height

Gauge Instrument Error (VHS-30D: ±0.04mm, VHS-60D:

±0.05mm)+Dial Indicator Wide Range Error (0.013mm)2. Insert the Scribe to desired overhang and secure by

tightening the Scribe Clamp Screw.

Overhang Adjustment

Indicator Clamp

Screw

Dial Indicator

30mm

Workpiece

③

0.00

④

30.00

Surface Plate Surface Plate

Surface Plate Surface Plate

Workpiece

Reference Surface

Surface to Measure

Surface to Measure

Reference Surface

①

0.00

②

0.00

Dial Indicator

②

Digital Height Gauge

Stylus

10.61mm

Workpiece

④

+0.10

③

10.51

Workpiece

①

0.00

0.00

Dial Indicator

Direction of

Measurement

Direction of

Measurement

Digital Height Gauge

Stylus

PLEASE NOTE

NOTE:

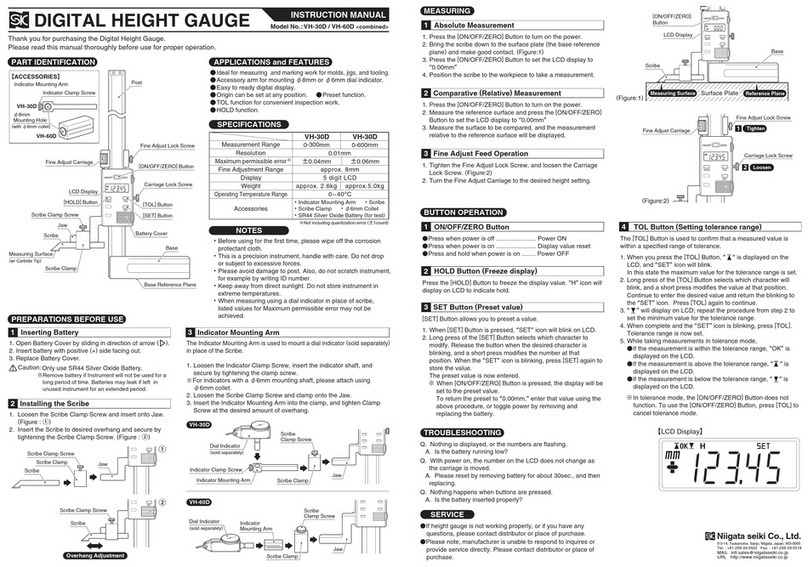

■Digital Height Gauge

・Max Measuring Height : VHS-30D…300mm

VHS-60D…600mm

・Resolution:0.01mm

・Instrument Error : VHS-30D…±0.04mm

VHS-60D…±0.05mm

※Instrument error will vary when used with dial indicator;

Please refer to section: “Instrument Error When Using

Accessory Dial Indicator (WTI-8038S)ʼʼ

・Fine Adjustment Range : 10mm

・Display : 5 Digit LCD

・Approx. Weight : VHS-30D…6.4kg

VHS-60D…7.5kg

・Power Supply : SR44 Silver Oxide Battery

・Included Accessories : Dial Indicator (WTI-8038S)

Dial Indicator Holder

SR44 Silver Oxide Battery (For test)

Driver for Battery Cover

■Dial Indicator WTI-8038S (Accessory)

・Measurement Range : 0−0.8mm

・Graduation : 0.01mm

・Scale Type : 0−40−0

・Wide Range Error : 0.013mm

・Retrace Error : 0.003mm

・Repeatability : 0.003mm

・Adjacent Error : 0.01mm

・Measurement Force : Less than 0.5N

・When using the Dial Indicator, make sure measuring element

(Stylus)is perpendicular to the direction of measurement. If

held at an angle, measurement will not be accurate.

・When measuring using a Dial Indicator in place of the Scribe,

specified values for instrument error (※)may not be

achieved.

※VHS-30D : ±0.04mm、VHS-60D : ±0.05m

SPECIFICATIONS

Direction of

Measurement

Direction of

Measurement

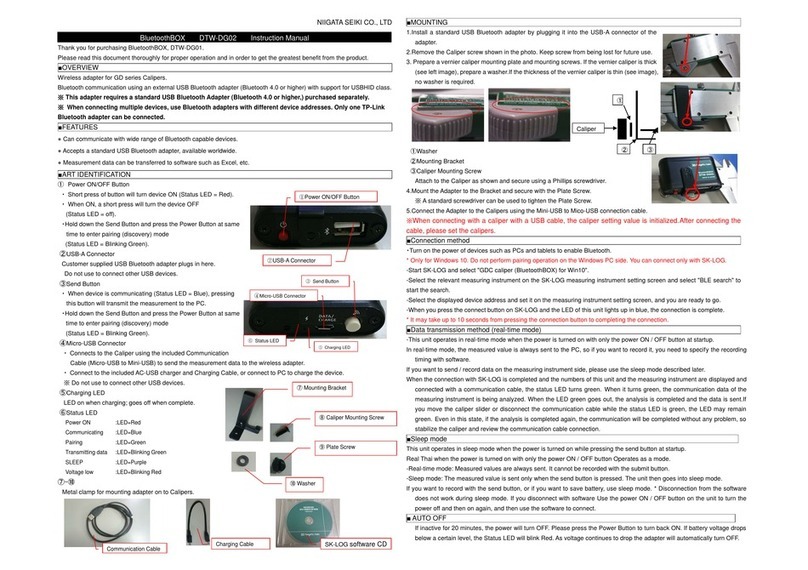

PREPARATION BEFORE USE

Inserting the Battery

1

1. Using the provided driver, remove the Battery Cover Screws.

2. Open the Battery cover by sliding in the direction of the

arrow ().

3. Insert the Battery with (+)side facing outward.

4. Return the Battery Cover to it's original position.

5. Replace the Battery Cover Screws to secure the cover.

Only use SR44 Silver Oxide Battery.

Installing the Scribe

2

1. Loosen the Scribe Clamp Screw and insert onto Jaw.

Dial Indicator Holder

3

The Dial Indicator Holder is used to mount the accessory dial

indicator in place of the Scribe.

1. Loosen the Indicator Clamp Screw, insert the indicator shaft,

and secure by tightening the clamp screw.

2. Loosen the Scribe Clamp Screw and place the Clamp onto

the Jaw.

3. Insert the Indicator Mounting Arm into the Clamp, and

tighten Clamp Screw at the desired amount of overhang.

NOTE: