3/4 A231-GB

IMPORTANT

- Installation should be carried out by qualied personnel only and in strict

conformity with the instructions supplied.

- For a correct installation all supplied components must be used, including

spacers and toothed washers.

- No variations are allowed, and only components indicated in the

package contents may be used.

- Given its purpose, the Exus LA BMC panic bar should be mounted on the

push-side of the door.

- Before proceeding with installation, check the package contents to ensure

that no pieces are missing.

- Check the type of lever handle to apply and follow the specic instructions.

- Any different installation conguration from that illustrated on page 2/4 is not

allowed.

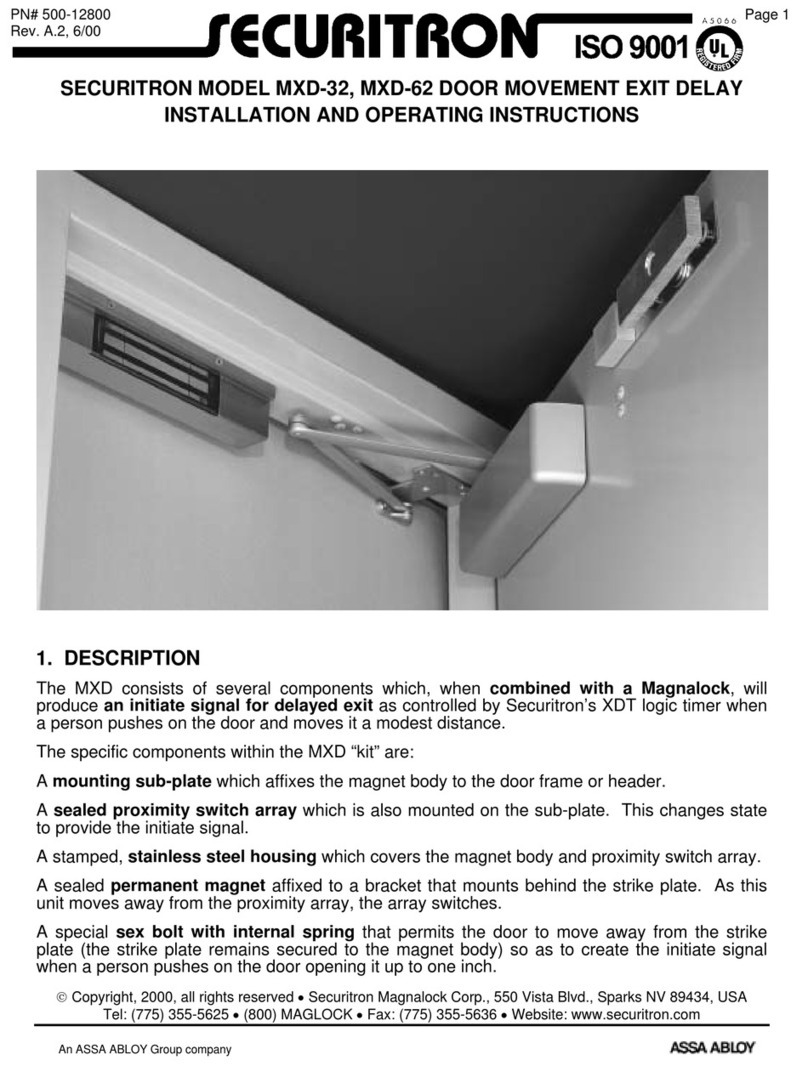

INSTALLATION

- First disassemble any handles or bar components that are already present.

- Unscrew the two frontal screws (28), and take away the existing lock (26).

Install the new panic safe lock (26) and fasten it with the same two frontal

screws (28).

- Adjust the plastic spacers (19 and 20) to the thickness of the leaf so that they

do not protrude from it.

- Adjust the threaded square spindle (13) to the thickness of the leaf so that it

protrudes 11±1mm from the door surface; be careful to cut the bevelled side.

- Insert the square spindles (13 and 14) into the lock (26) for connecting them

by tightening the respective screw (15).

- Screw onto installation plate of stainless steel handle (11) the screws (24),

just enough to insert the cover plate (12).

- Insert the two threaded inserts (16) in the installation plate of handle (11),

making sure that they are well-centred.

- Insert the two spacers (19 and 20) over the threaded inserts (16) and apply

the handle on the pull-side of the door, being careful to center the square

spindle and the inserts over their respective holes.

- Apply the operating mechanism (1) to the lock side (push-side of the door)

after inserting the screws (17), toothed washers (18) and spacer (20). Center

the square spindle and screws, starting the screws by hand before fastening

them with the screwdriver.

- Use the template to drill the holes (29) with the Ø3mm drill bit, checking

the level. If holes are already present, drill them again for the internal

reinforcement.

- Fasten the mechanism (1) even more securely with the self-tapping screws

Ø4,8x16mm (22) and their toothed washers (18).

- Fasten the mechanism (2) of the panic bar at hinged side, using the self-

tapping screws Ø4,8x16mm (22) and their toothed washers (18).

- Remove the externally-facing plugs (5) from both carter (3 and 4). To do

this, insert a nger inside the carter and push the plug out, being careful

not to remove the plastic insert. Apply the carter with “EXIT” wording (3) on

the operating mechanism (1) and the other one (4) on the mechanism from

hinged side (2). Do not fasten the socked set screws, so as to let the two

carter movable.

- Apply the carrier arms (6) and fasten them with the dedicated screws (7),

tightening them securely using a Phillips-head screwdriver.

- Make a precise “L” measurement, cut the aluminium bar (10) adding 20mm,

and remove the burrs from the cut edge. Remove one carrier arm, attach the

bar and re-fasten the entire assembly.

- Finish fastening of the two carter (3 and 4), screw on without overtighten the

socked set screw, using the S2 hex key (25), then apply the plugs (5).

- Insert the two caps (21) in the open holes of the panic safe lock (26).

- Push the Exus LA BMC panic bar at any point along the horizontal bar,

checking to ensure that the latch bolt of the lock opens easily and fully.

Use the same method to check the external handle. Test the door in

both open and closed positions and if necessary, le down the plastic

strike box (27) of one-leaved doors or the panic safe lock for inactive

leaf of two-leaved doors.

- Fasten the installation plate of stainless steel handle (11) using the

Ø4,2x13mm self-tapping screws (23) and their toothed washers (18) after

drilling holes in the metal panel with the Ø2mm drill bit. Insert the cover (12)

onto the handle (drw. 2). Using the S2 hex key (25) to unscrew the screws

(24) until the cover become xed, avoiding any deformations (drw. 3). Insert

and fasten the socket set screw well with the S3 hex key (8).

- Apply the pictogram (9) with the green arrow on the internal surface of the

door, just above the horizontal bar.

- Lastly, use a dynamometer to measure the force required on the

horizontal bar to release the lock. Record this force measurement in

the present document.

USE

- Ensure that the door always opens easily.

- Avoid unnecessary strains on or handling onto handle and exit bar.

- Protect the panic bar from external atmospheric agents.

- Ensure that nothing hinders the free movement of the horizontal bar.

- Do not paint the lock.

- Use the bar properly, do not pull it in the wrong direction.

- Make sure that any damaged or malfunctioning parts are replaced

immediately.

MAINTENANCE

To ensure that door usage conforms with regulations, the following maintenance

checks should be carried out at least once a month:

- Conrm that all of the installed components correspond with those listed in the

present instructions and that no other latching devices than those originally

installed have been added to the door.

- Inspect and activate the panic bar to verify that all of its components are in

satisfactory operational condition.

- Use a dynamometer to conrm that the release force shows no signicant

differences from the forces recorded at the time of installation.

- Check whether all screws are fully tightened, tightening any that may

have loosened.

- Check whether panic bar and handle can be moved with minimal effort,

and that the latch bolt of the safe lock retreats from the strike box without

offering resistance. If the door has become difcult to open due to friction,

the resistance can be reduced by ling the strike box down to the appropriate

height.

- Activate the Exus LA BMC panic bar at both ends of the horizontal bar,

checking to ensure full retraction of the latch bolt in both cases.

- Ensure that the latch bolt exits completely when the horizontal bar is released.

- Check the horizontal bar and replace it if any damage or deformities are

detected.

- Check whether the inserts and strike boxes are blocked in any way

and eliminate any obstructions.

- This product requires no special maintenance. Grease spray should be used

to lubricate the internal workings of lock, handle and panic bar on a regular

basis – the latter has a hole on its carter for this purpose, located below the

carrier arms.

- For normal cleaning use a cleaning agent designed specically for chrome-

polished surfaces for the horizontal bar and another one designed specically

for stainless steel for the handle.

- Any adjustments that become necessary must be carried out by

qualied personnel using original NINZ replacement parts.

- The owner of the activity is responsible for keeping the declaration of

correct installation on le, conducting proper panic bar maintenance

in accordance with all of the manufacturer’s maintenance guidelines,

keeping maintenance and check-up records and preserving the

present document.