3

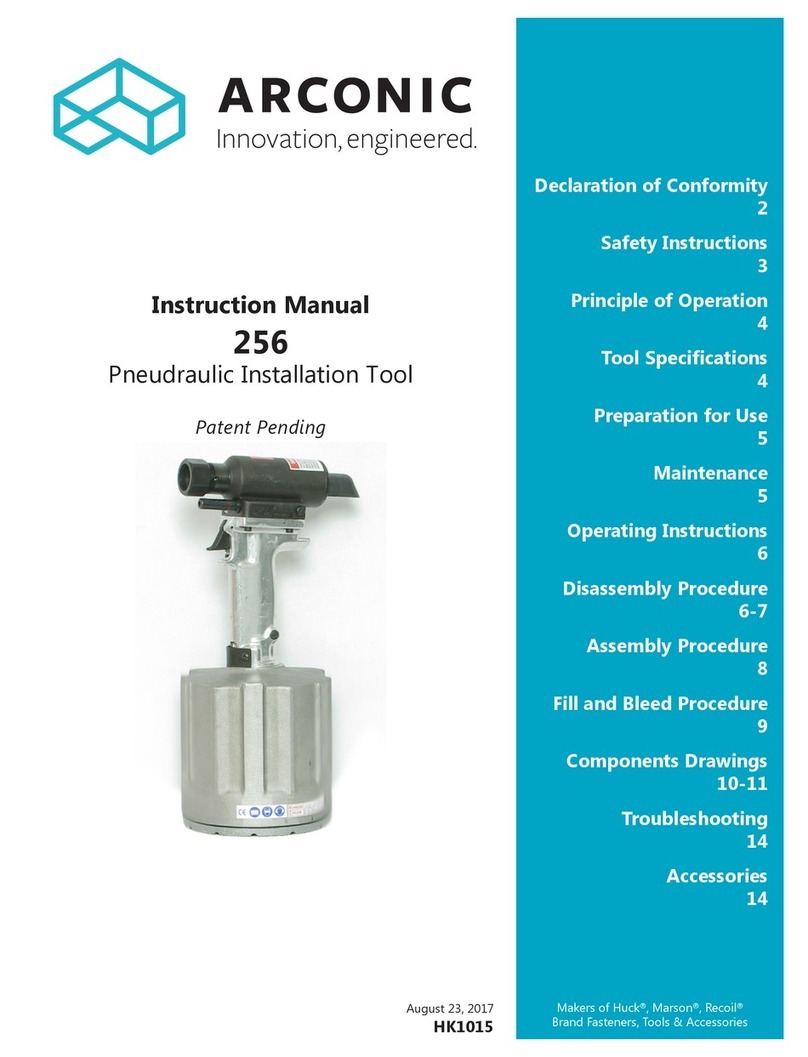

2013 & 2014 series Pneudraulic Installation Tools (HK978)

I. GENERAL SAFETY RULES:

serious bodily injury.

required, and listed in the manual, are legibly marked on the tool. The

9. Tool is only to be used as stated in this manual. Any other use is

may occur.

before installing the next fastener.

clear from front of tool.

installed.

II. PROJECTILE HAZARDS:

inserted tools or accessories.

5. The risk of others should also be assessed at this time.

front of tool.

III. OPERATING HAZARDS:

3. Hold the tool correctly and be ready to counteract normal or sudden

IV. REPETITIVE MOTION HAZARDS:

body.

discomfort and fatigue.

V. ACCESSORIES HAZARDS:

accessory.

consumables.

VI. WORKPLACE HAZARDS:

2. Proceed with caution while in unfamiliar surroundings; there could be

VII. NOISE HAZARDS:

VIII. VIBRATION HAZARDS:

warm and dry.

IX. PNEUMATIC / PNEUDRAULIC TOOL SAFETY INSTRUCTIONS:

5. Cold air should be directed away from hands.

Safety Instructions

Bold, Italic type, and underline:

instruction.

WARNINGS: Must be understood to avoid

severe personal injury.

CAUTIONS: Show conditions that will damage

equipment or structure.