krk622en1905h ♦ page 2

3. INSTALLATION

A KRK–622– switching unit can be mounted on DIN EN 60715 rail.

It is recommended the KLN–2 type probes to be cut to the length required for level detec-

tion on site. The probes should be screwed into the KS–0 type sockets.

ALWAYS REMEMBER TO TIGHTEN THE PROBE WITH AN M6 NUT!

When using KSH–204 type probe sockets the reference probes should be tightened with spe-

cial SW hexagonal M6 nuts!

It is suggested KLP–201 or KLP–204 type PVDF separators (suitable up to +130 °C) to be

used at every 0.5 m for multiple probe devices to keep the probes apart.

A KSK–201 single probe, attached to an insulated cable, can be lowered into pits and wells

without running the risk of a short circuit. When a detection is needed in a well or in a plastic

pipe 2 of them have to be used. For additional levels additional probes should be used.

4. WIRING

If the wall of the tank is conductive no reference probe is needed. In this case terminal ‘C’

has to be connected to the tank.

On multiple probe units ‘E1’ and ‘E2’ are marked with 1–4, the reference probe is marked

with ‘C’. Admissible length of cable between switching unit and probes depends on cable

capacitance and conductivity.

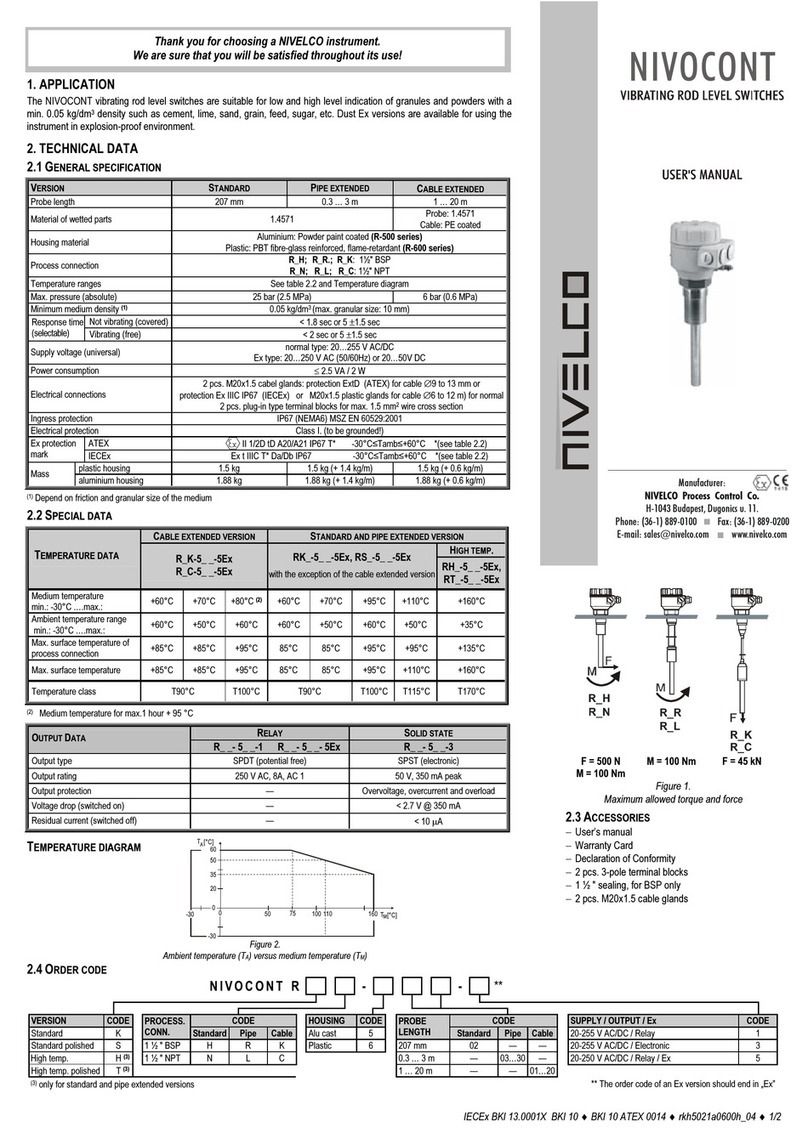

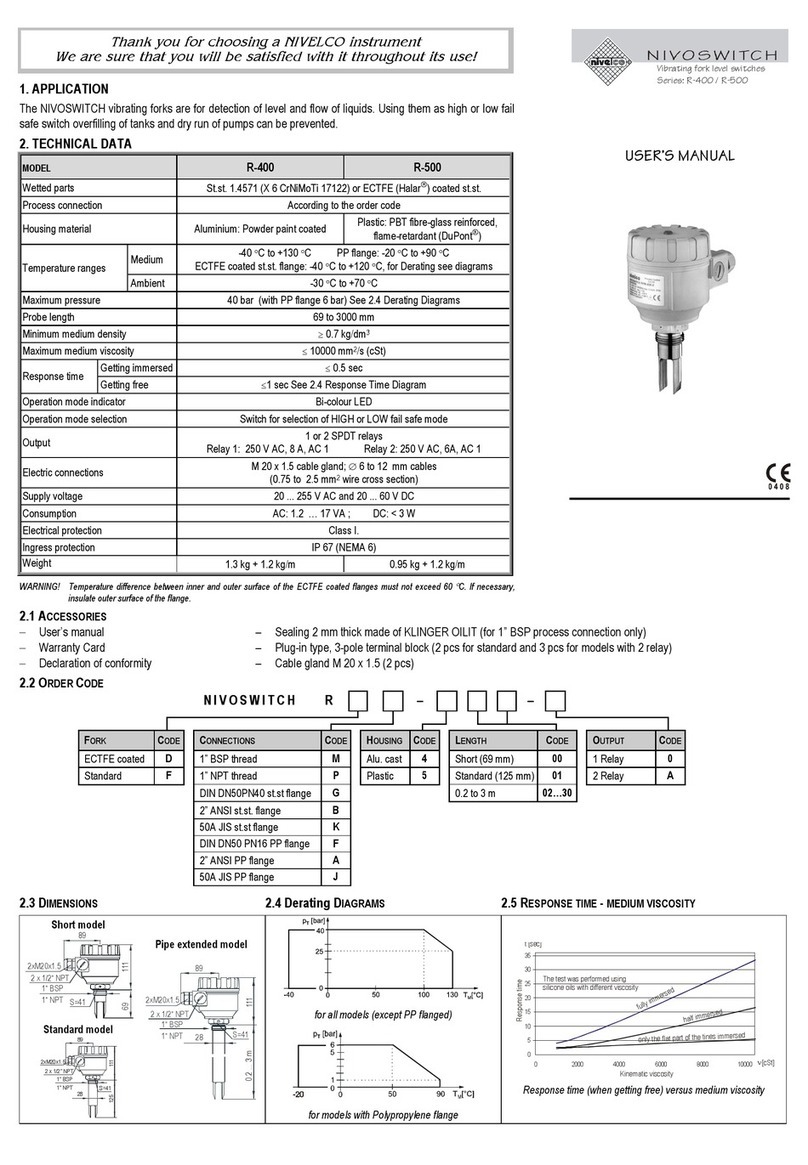

The terminal block assignment of KRK–622–1 and KRK–622–2 is not the same, the

KRK–622–4 is different. There is no ‘S’ terminal at the KRK–622–1 and KRK–622–2. Refer-

ring to the illustration below for the terminal block assignments of the devices.

Example of setting DIP switch:

Select the desired function in accordance with the gures. The upper 3 switches are for select-

ing the number of the function you want to use. If you want to use Function 5 you should set

the switches as follows: set the 1st switch to the right, the 2nd to the left and the 3rd to the left.

Then select whether you need ON delay or OFF delay with the 4th switch. You can choose the

type of delay, but you cannot deactivate the delay. However, the minimum delay time you can

set with the potentiometers is 0.5 seconds.

The DIP switch looks like this after setting function 5 with an OFF delay:

Un

OUT2

S

E1E2

C

A2A1

OUT1

16 15 18 28 25 26

Un

KRK–622–1,–2 KRK–622–4

C

E2

E1

E2

C

A2A1 E1

OUT2OUT1

16 15 18 28 25 26

A1, A2 – power supply S – shielding

C – reference probe 15, 16, 18 – 1st relay output – pump control 1

E1 – max. probe (OUT1) 25, 26, 28 – 2nd relay output – pump control 2

E2 – min. probe (OUT2) (function 1, 2, 3, 4) or alarm (function 5, 6, 7, 8)

To eliminate signal interferences it is recommended to use shielded cables to the probes.

5. COMMISSIONING

5.1. ADJUSTMENT

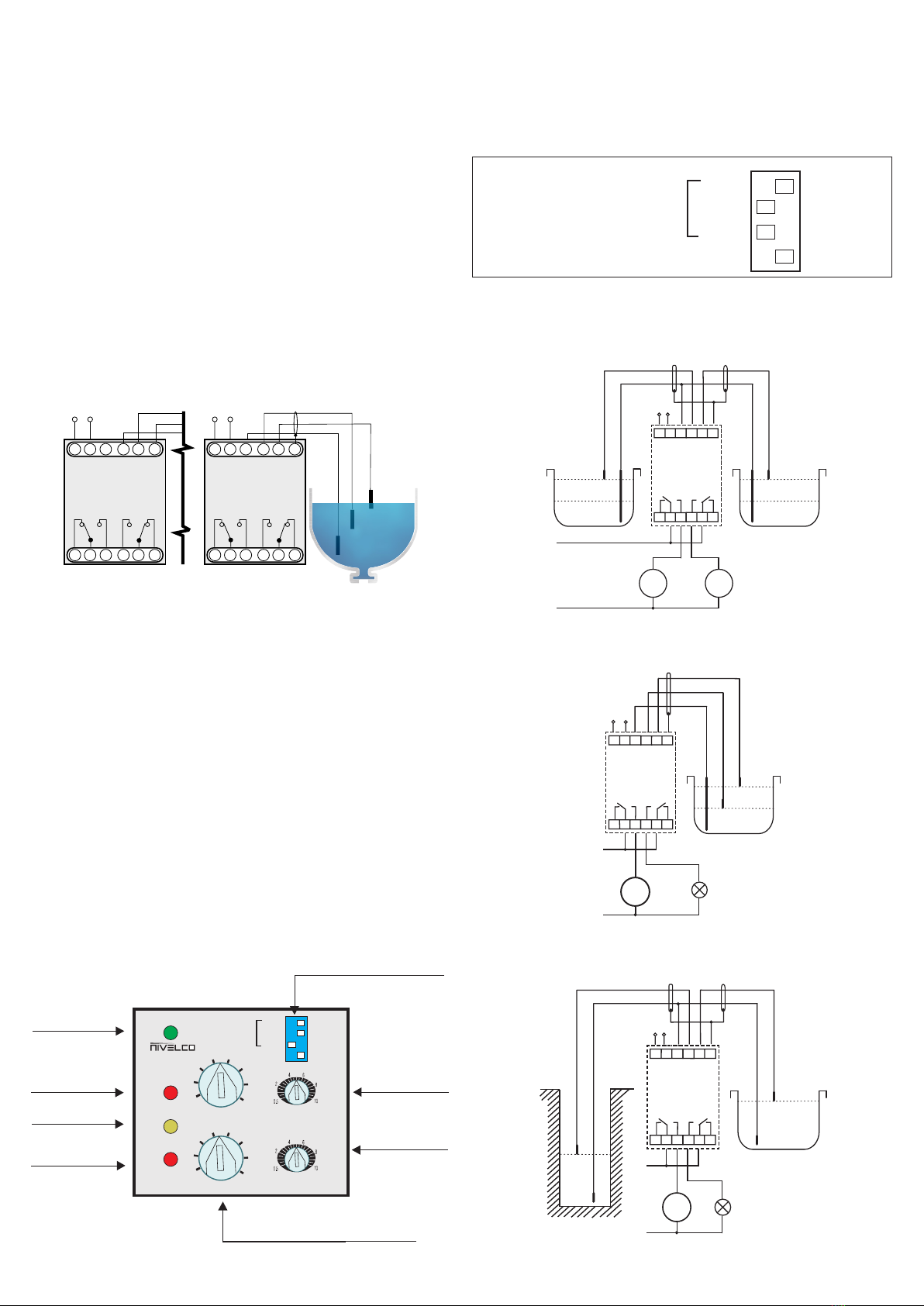

The green LED (Un) shows that the unit is on, the energised state of the relays are indicated by

the OUT1 respectively OUT2 LEDs. If the OUT1, OUT2 (red) LEDs are ashing, they indicate

the timer operation. When they light up, it shows that the corresponding relay is switched

on. Yellow LED (FAIL) indicates probe failure (for example at Functions 5 and 6 probe ‘E1’ is

ooded and probe ‘E2’ is not, which is unreal state so the yellow LED is on.)

Operating modes, delay ON and delay OFF can be set with the DIP switch on the front panel.

t1[s] and t2[s] potentiometers are for adjusting the delay time. The delay value can change

from 0.5 seconds to 10 seconds. You can set the sensitivity of the two probes independently

using the RE1 or RE2 potentiometers. The sensitivity setting should comply with the conduc-

tivity of the uid. Do not set sensitivity higher than required because the vapour precipitation

may lead to operation disturbance. In heavily humid environment insulated probes can be

used. With the ON Delay / OFF Delay switch on the DIP switch, delay type of the relays can

be selected (switch-on delay or switch-off delay).

5

10

20

30 50

70

90

100

t [s]

1

t [s]

2

KRK22–6

Un

OUT1

OUT2

FAIL

10

30 50

70

90

100

R[ ]

E1 Ωk

OFF

Delay

ON

Delay

Function

1,2,3,4

1,2,5,6

1,3,5,7

20

R[ ]

E2 Ωk

5,6,7,8

3,4,7,8

2,4,6,8

5

OUT2 switching

indication

Delay adjustment

for Relay 1

DIP switch

(Function 7 is showed on the picture)

Delay adjustment

for Relay 2

2 rotary potentiometers for adjusting the

sensitivity for E1 and E2 probes independently

according to the conductivity of the uid

Probe failure

OUT1 switching

indication

Supply voltage

indication

1st switch to right

2nd switch to left

3rd switch to left

Function

1, 2, 3, 4

1, 2, 5, 6

1, 3, 5, 7

5, 6, 7, 8

3, 4, 7, 8

2, 4, 6, 8

ON DelayTo off delay switch to right OFF Delay

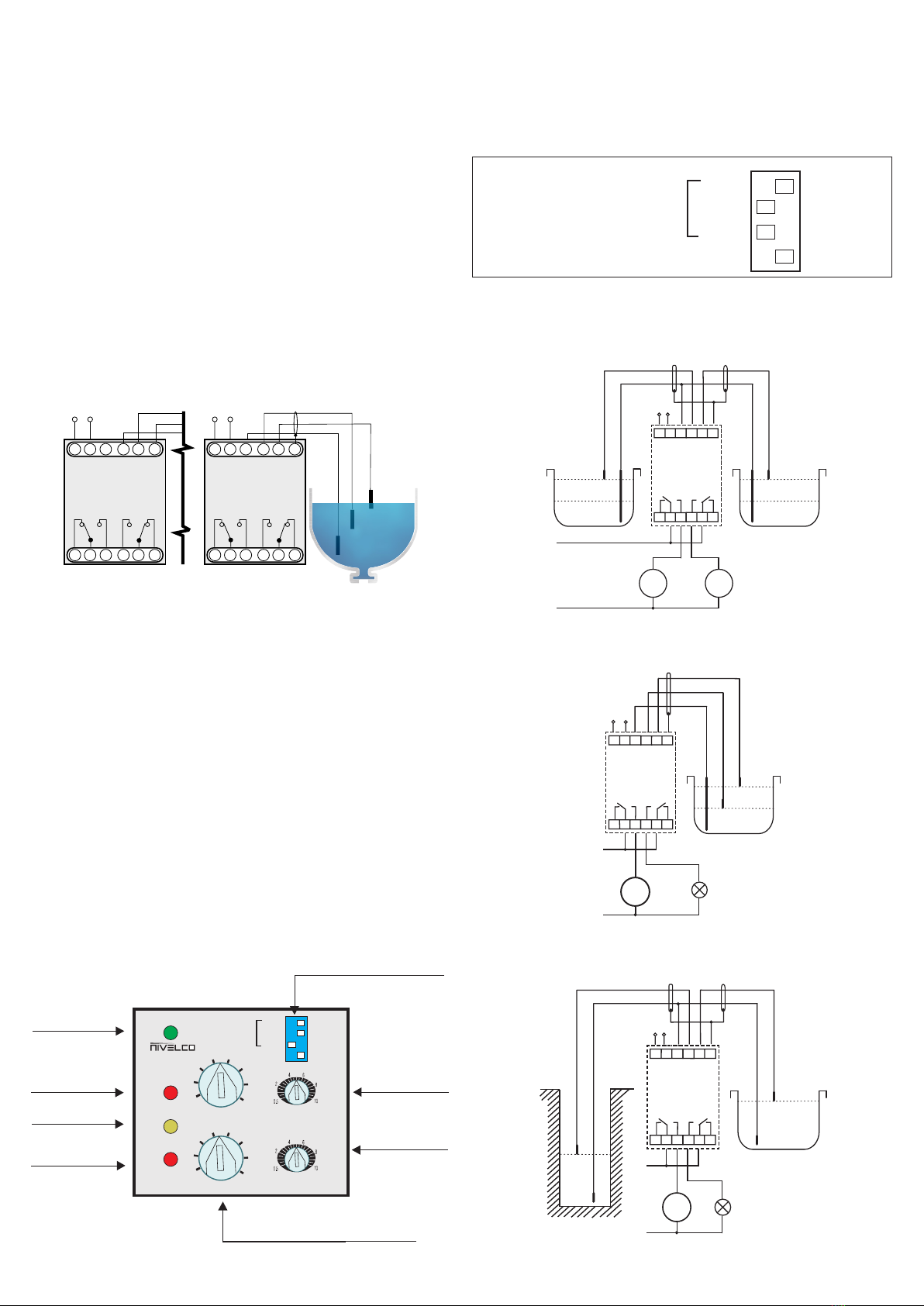

5.2 FUNCTIONS

Attention! The following wiring diagrams show the wiring of the KRK–622–4,

24 V supply voltage device.

Functions 1 to 4 are for controlling 2 pumps according to the following picture:

A1 A2 C E2 E1 S

16 15 18 28 25 26

Un

L

N

E2

CC E1

OUT 1 OUT 2

Tank I.

Pump 1 Pump 2

Tank II.

Functions 5 and 6 are for controlling one pump (lling or emptying one tank) and for generating

alarm signal according to the following picture. If level is not between ‘E1’ and ‘E2’ alarm is

generated:

A1 A2 C E2 E1 S

16 15 18 28 25 26

Un

L

N

C

E2

E1

max.

min.

OUT 1 OUT 2

Tank

Alarm

Pump

Functions 7 and 8 also controls one pump and generates one alarm signal:

A1 A2 C E2 E1 S

16 15 18 28 25 26

Un

L

N

OUT 1 OUT 2

E2

C C E1

Alarm

Well

Reservoir

Tank

Pump

Front panel of NIVOCONT KRK–622