rcm400en2112h 1/4

Thank you for choosing a NIVELCO instrument!

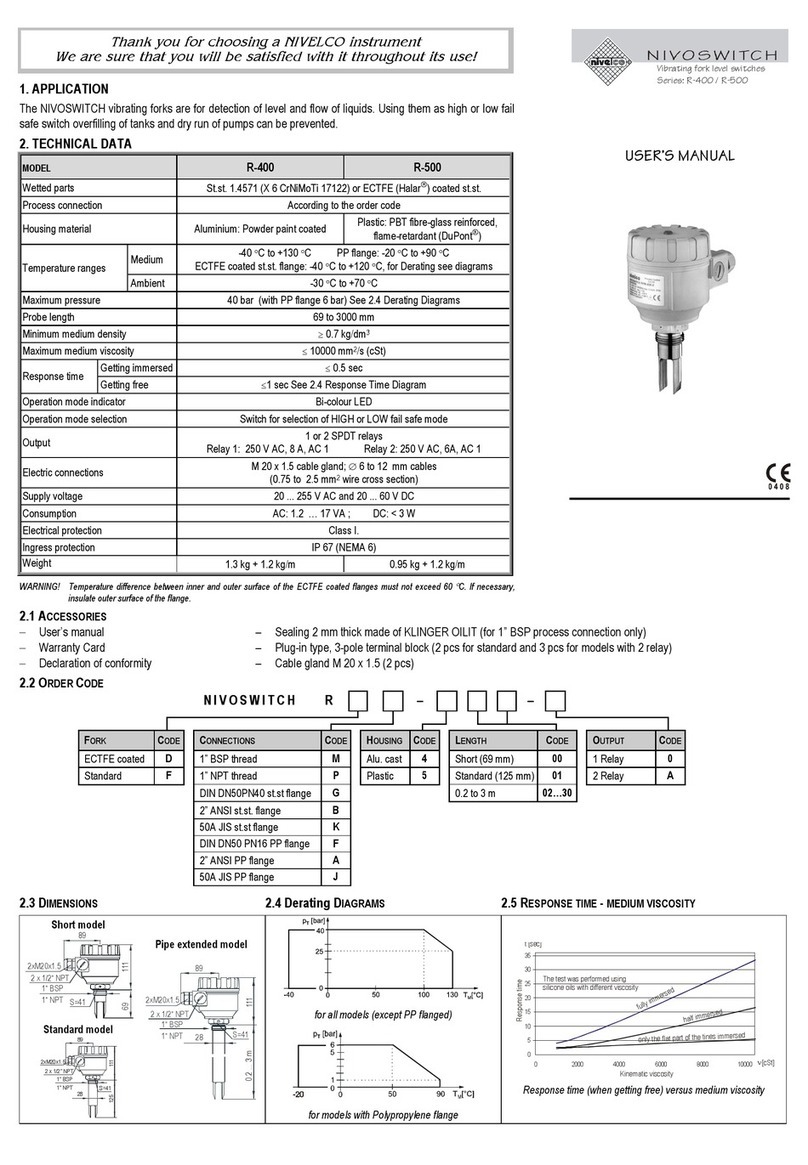

1. APPLICATION

The NIVOSWITCH R–400 vibrating fork level switches are used for level or flow switching tasks of normal

and explosive liquids. Overfill and dry run protection, as well as pump control, are also possible with the

NIVOSWITCH vibrating fork level switches in low/high fail-safe operating mode.

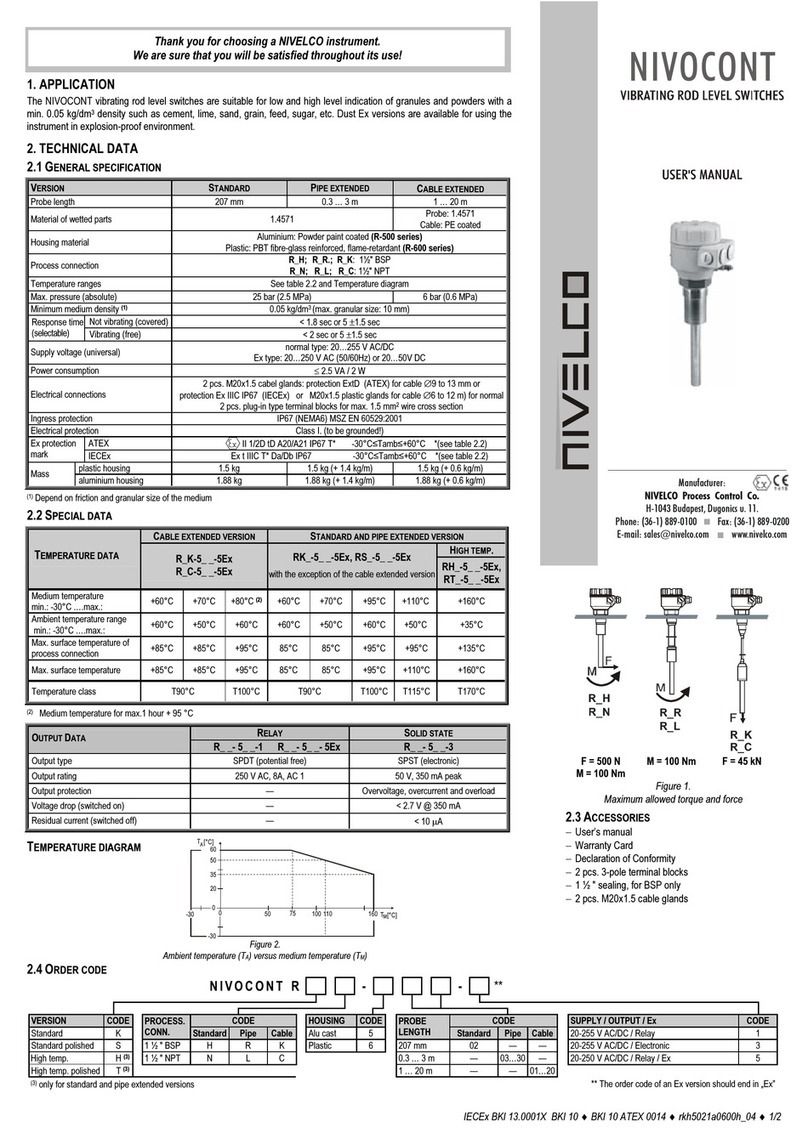

2. TECHNICAL DATA

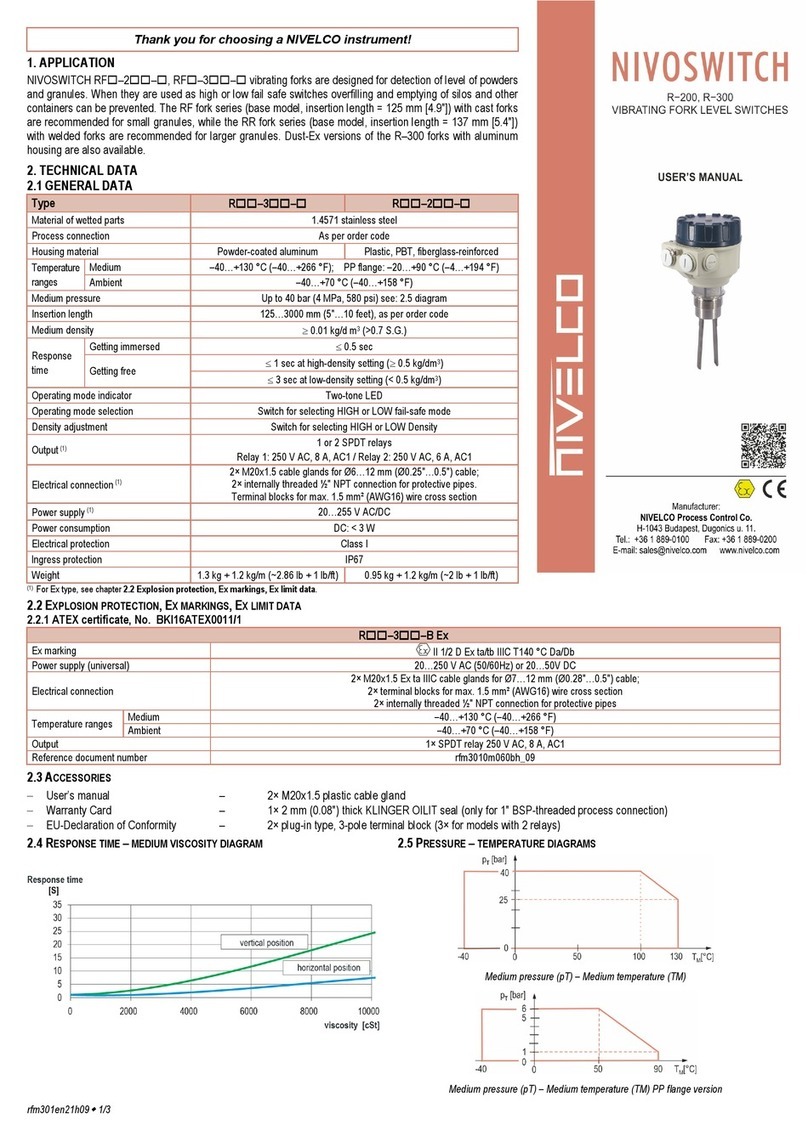

2.1 GENERAL DATA 2.2 2-WIRE DC, NORMAL AND EX APPROVED VERSION

R–4–6

R–4–Ex

Típus Type R–4–6

R–4–8Ex

R–4–K

R–4–LEx

R–4–7

R–4–9Ex

Medium pressure

40 bar (580 psi),

PP flange: 6 bar (87 psi)

see “Temperature diagrams”

Electrical connection Connector

3 m (10 ft) (1) cable

(2 x 0.5 mm2

[AWG20])

Insertion length 69…3000 mm (0.225…10 ft) Ingress Protection IP65 IP67 IP68

Material of wetted

parts

DIN 1.4571,

ECTFE / PFA coating Output

DC current change:

When free: 9 ±1 mA;

When immersed: 14 ±1 m

Medium

temperature

−40…+130 °C (−40…+266 °F)

see section 5.1 and 2.6

diagrams

Consumption < 0.5 W

Power supply (U)

15…29 V DC

Provided by the PKK–312–8Ex

remote switching unit for the Ex-version

Ambient

temperature

−40…+70 °C (−40…+158 °F)

see table in 5.1 and diagrams

R–4–L Ex;

R–4–M and –4–

K

−25…+70 °C (−13…+158 °F)

Setting operation

mode

By switch on the remote switching unit

(Low fail-safe – “L”, High fail-safe – “H”)

Medium-density 0.7 kg/dm3Electrical protection Class III.

Medium viscosity 10000 mm2/s (cSt)

Respons

e time

When

immersed 0.5 sec

Ex marking

(RC–4–Ex,

RG

4

Ex)

II 1G Ex ia IIC T6…T4 Ga

When free When free: 1 s

see response time diagram Ex marking

(RB–4–Ex) II 1G Ex ia IIB T6…T4 Ga

Output mode

indication Bi-color (LED) Intrinsic safety data

Ui= 29 V; Ii= 100 mA; Pi= 1,4 W;

Ci= 7 nF; Li= 0 mH

Ui= 29 V; Ii= 100 mA;

Pi= 1,4 W;

Ci= 15 nF; Li= 0 mH

Operation test Output can be toggled

by test magnet

For temperature classes, see section 5.1

Reference document

numbe

rcm4004m060bh_11

(1) Available max. cable length 30 m (100 ft)

2.3 2-WIRE AC AND 3-WIRE DC VERSIONS

TYPE 2-WIRE AC 3-WIRE DC

R

4–1 R

4–2 R–4–3 R–4–M R–4–4

Electrical connection (wire cross section) Connector

3 m (10 feet) integral cable,

4 x 0.75 mm2(AWG18)

(max cable length 30 m [100 feet])

Connector

3 m (10 feet) integral cable,

5 x 0.5 mm2(AWG20)

(max. cable length 30 m [100 feet])

Mechanical protection IP65 IP68 IP65 IP67 IP68

High/low mode setting

(Low fail-safe

“L”, High fail-safe

“H”)

Determined by the wiring inside

the connecto

Determined by the wiring Switch selectable Connection within

connecto

Wire selectable

Output 2-wire AC, for serial connection Field selectable,

NPN / PNP transistor switch

Field selectable, galvanically

isolated PNP/NPN transistor switch

Output protection — Reverse polarity, over

urrent and short-circuit protection

Supply voltage 20…255 V AC, 50/60 Hz 12…55 V DC

Consumption Depending on the load < 0.6 W

Voltage drop when switched on < 10.5 V < 4.5 V

Electrical protection Class I Class III

Load current

max. continuous 350 mA

C 13 Imax = 350 mA DC / Umax = 55 V DC

min. continuous 10 mA / 255 V, 25 mA / 24 V

max. impulse 1.5 A / 40 ms

Residual current (in switched off state) < 6 mA < 100

A

2.4 ACCESSORIES

- User’s manual - EU- declaration of conformity

ccessories (sold separately): -

djustable sliding sleeve (RPH

112

0)

- Warranty Card - 1× Sealing ring (2 mm [0.079"] thick Klinger Oilit) - Test magnetic-screwdriver (RPS

101)

2.5 ORDER CODES NIVOSWITCH R –

4 – *

TYPE CODE PROCESS CONNECTION CODE PROBE LENGTH CODE OUTPUT CODE

Tube + plastic

(ECTFE / PFA) coated fork B 1" BSP M Short (69 mm [2.7"]) 00 2-wire

C + connecto

1

1½" BSP H Standard (125 mm [4.9"]) 01 2-wire

C + cable 2

Tube + for

: 1.4571 C 1" NPT P 0.2…3 m (0.66…10 feet) 02…30 3-wire DC + connecto

3

Tube + highly polished fork G 1½" NPT N 3-wire DC + cable 4

Tube + for

: 1.457, without reed senso

(1) E DN50 PN16 PP DIN F 2-wire DC + connecto

6

(1)Ex version not available DN50 PN40 1.4571 DIN G 2-wire DC + cable 7

NSI 2" RF150 PP

2-wire DC + connector + E

8

NSI 2" RF600 1.4571 B 2-wire DC + cable + E

9

JIS 10K 50A PP J 2-wire DC + M12 connecto

K

JIS 40K 50A 1.4571 K 2-wire DC + M12 connector + E

L

TriClamp 1½" T 3-wire DC + M12 connecto

M

TriClamp 2" R

DN40 Pipe coupling D * Ex version with E

mark

DN50 Pipe coupling E Note: Flanged versions have 1" process connection