rfm301en21h09

1/3

Thank you for choosing a NIVELCO instrument!

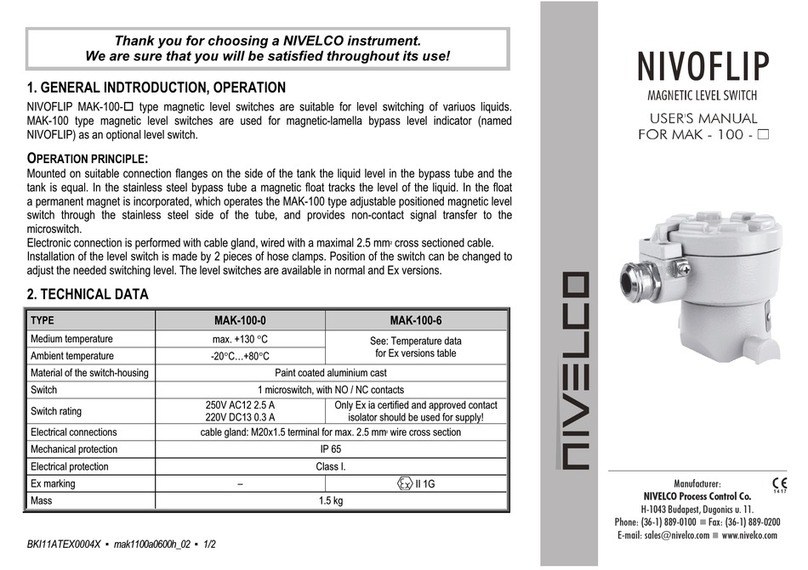

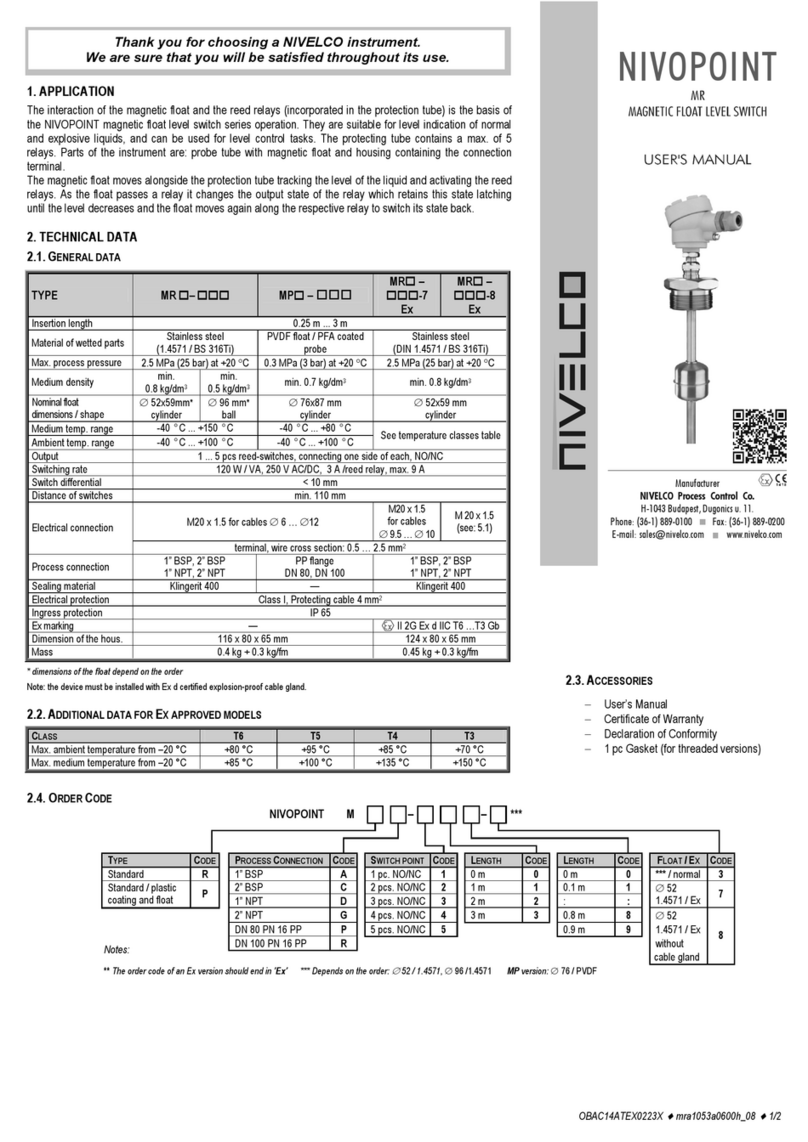

1. APPLICATION

NIVOSWITCH RF–2–, RF–3–vibrating forks are designed for detection of level of powders

and granules. When they are used as high or low fail safe switches overfilling and emptying of silos and other

containers can be prevented. The RF fork series (base model, insertion length = 125 mm [4.9"]) with cast forks

are recommended for small granules, while the RR fork series (base model, insertion length = 137 mm [5.4"])

with welded forks are recommended for larger granules. Dust-Ex versions of the R–300 forks with aluminum

housing are also available.

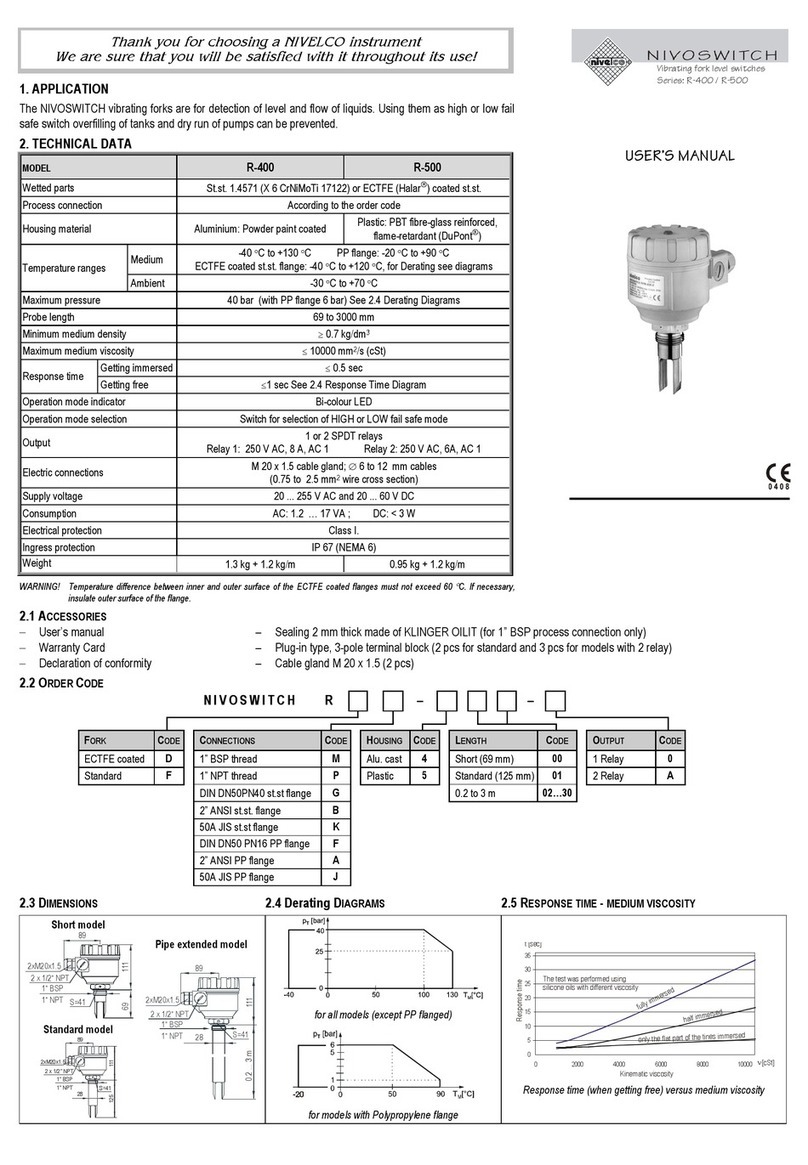

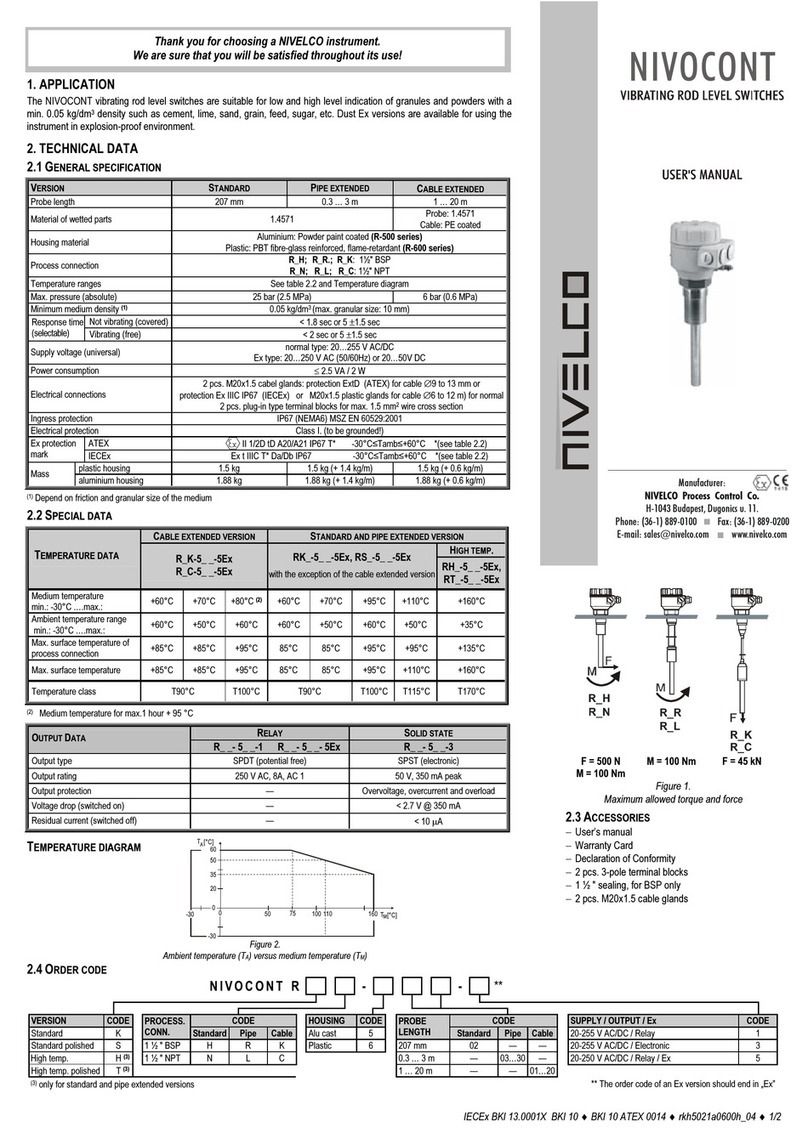

2. TECHNICAL DATA

2.1 GENERAL DATA

Type R–3–R–2–

Material of wetted parts 1.4571 stainless steel

Process connection As per order code

Housing material Powder-coated aluminum Plastic, PBT, fiberglass-reinforced

Temperature

ranges

Medium –40…+130 °C (–40…+266 °F); PP flange: –20…+90 °C (–4…+194 °F)

Ambient –40…+70 °C (–40…+158 °F)

Medium pressure Up to 40 bar (4 MPa, 580 psi) see: 2.5 diagram

Insertion length 125…3000 mm (5″…10 feet), as per order code

Medium density 0.01 kg/d m3(>0.7 S.G.)

Response

time

Getting immersed 0.5 sec

Getting free 1 sec at high-density setting (0.5 kg/dm3)

3 sec at low-density setting (< 0.5 kg/dm3)

Operating mode indicator Two-tone LED

Operating mode selection Switch for selecting HIGH or LOW fail-safe mode

Density adjustment Switch for selecting HIGH or LOW Density

Output (1) 1 or 2 SPDT relays

Relay 1: 250 V AC, 8 A, AC1 / Relay 2: 250 V AC, 6 A, AC1

Electrical connection (1)

2× M20x1.5 cable glands for Ø6…12 mm (Ø0.25″…0.5″) cable;

2× internally threaded ½″NPT connection for protective pipes.

Terminal blocks for max. 1.5 mm² (AWG16) wire cross section

Power supply (1) 20…255 V AC/DC

Power consumption DC: < 3 W

Electrical protection Class I

lngress protection IP67

Weight 1.3 kg + 1.2 kg/m (~2.86 lb + 1 lb/ft) 0.95 kg + 1.2 kg/m (~2 lb + 1 lb/ft)

(1) For Ex type, see chapter 2.2 Explosion protection, Ex markings, Ex limit data.

2.2 EXPLOSION PROTECTION,EX MARKINGS,EX LIMIT DATA

2.2.1 ATEX certificate, No. BKI16ATEX0011/1

R

3

B Ex

Ex marking II 1/2 D Ex ta/tb IIIC T140 °C Da/Db

Power supply (universal) 20…250 V AC (50/60Hz) or 20…50V DC

Electrical connection

2× M20x1.5 Ex ta IIIC cable glands for Ø7…12 mm (Ø0.28″…0.5″) cable;

2× terminal blocks for max. 1.5 mm² (AWG16) wire cross section

2× internally threaded ½″NPT connection for protective pipes

Temperature ranges Medium

40…+130 °C (

40…+266 °F)

mbient

40…+70 °C (

40…+158 °F)

Output 1× SPDT relay 250 V

C, 8 A, AC1

Reference document number rfm3010m060bh_09

2.3 ACCESSORIES

User’s manual – 2× M20x1.5 plastic cable gland

Warranty Card – 1× 2 mm (0.08″) thick KLINGER OILIT seal (only for 1" BSP-threaded process connection)

EU-Declaration of Conformity – 2× plug-in type, 3-pole terminal block (3× for models with 2 relays)

2.4 RESPONSE TIME –MEDIUM VISCOSITY DIAGRAM

2.5 PRESSURE –TEMPERATURE DIAGRAMS

Medium pressure (pT) – Medium temperature (TM)

Medium pressure (pT) – Medium temperature (TM) PP flange version