Thank you for choosing a NIVELCO instrument

We are sure that you will be satisfied with it throughout its use!

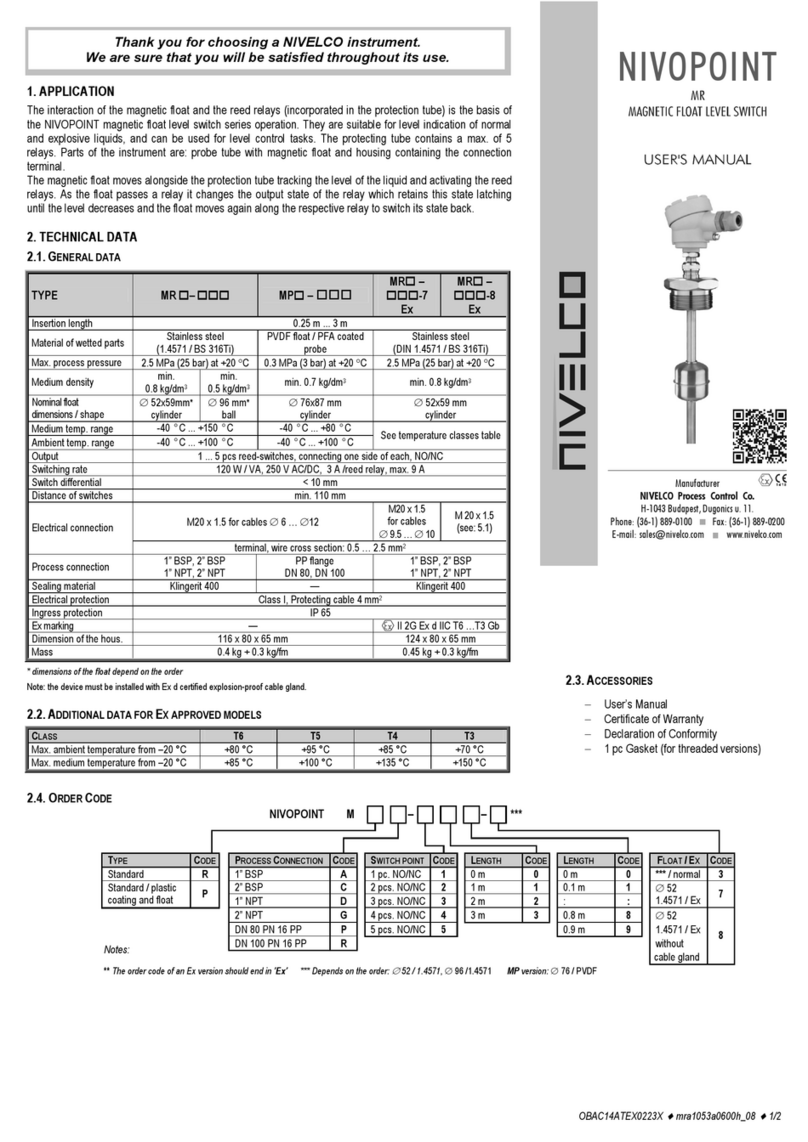

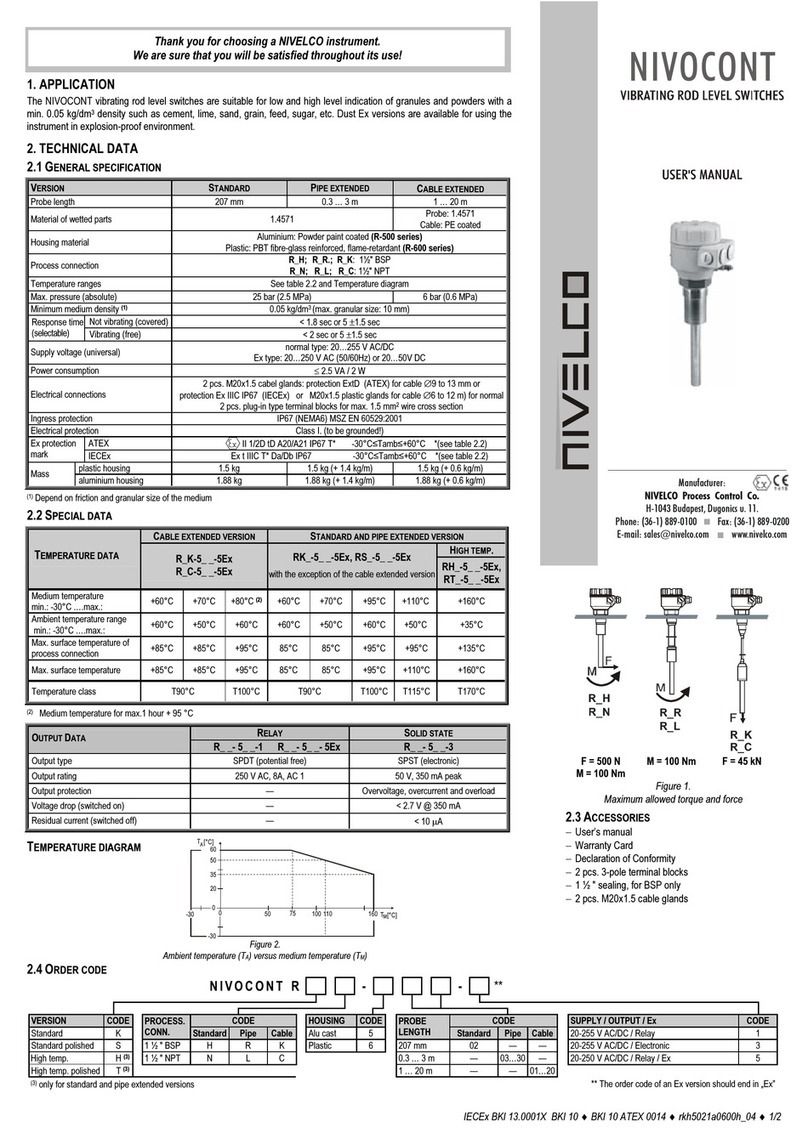

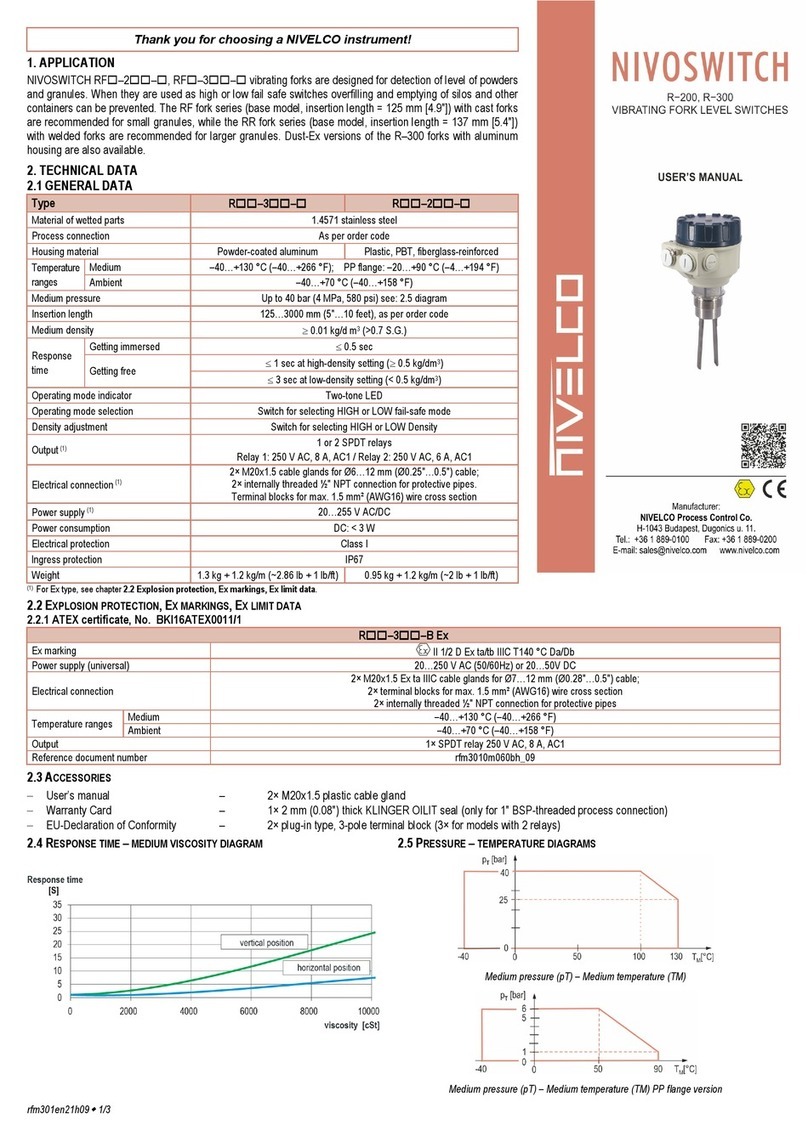

1. APPLICATION

The NIVOSWITCH vibrating forks are for detection of level and flow of liquids. Using them as high or low fail

safe switch overfilling of tanks and dry run of pumps can be prevented.

2. TECHNICAL DATA

MODEL R-400 R-500

Wetted parts St.st. 1.4571 (X 6 CrNiMoTi 17122) or ECTFE (Halar) coated st.st.

Process connection According to the order code

Housing material Aluminium: Powder paint coated Plastic: PBT fibre-glass reinforced,

flame-retardant (DuPont)

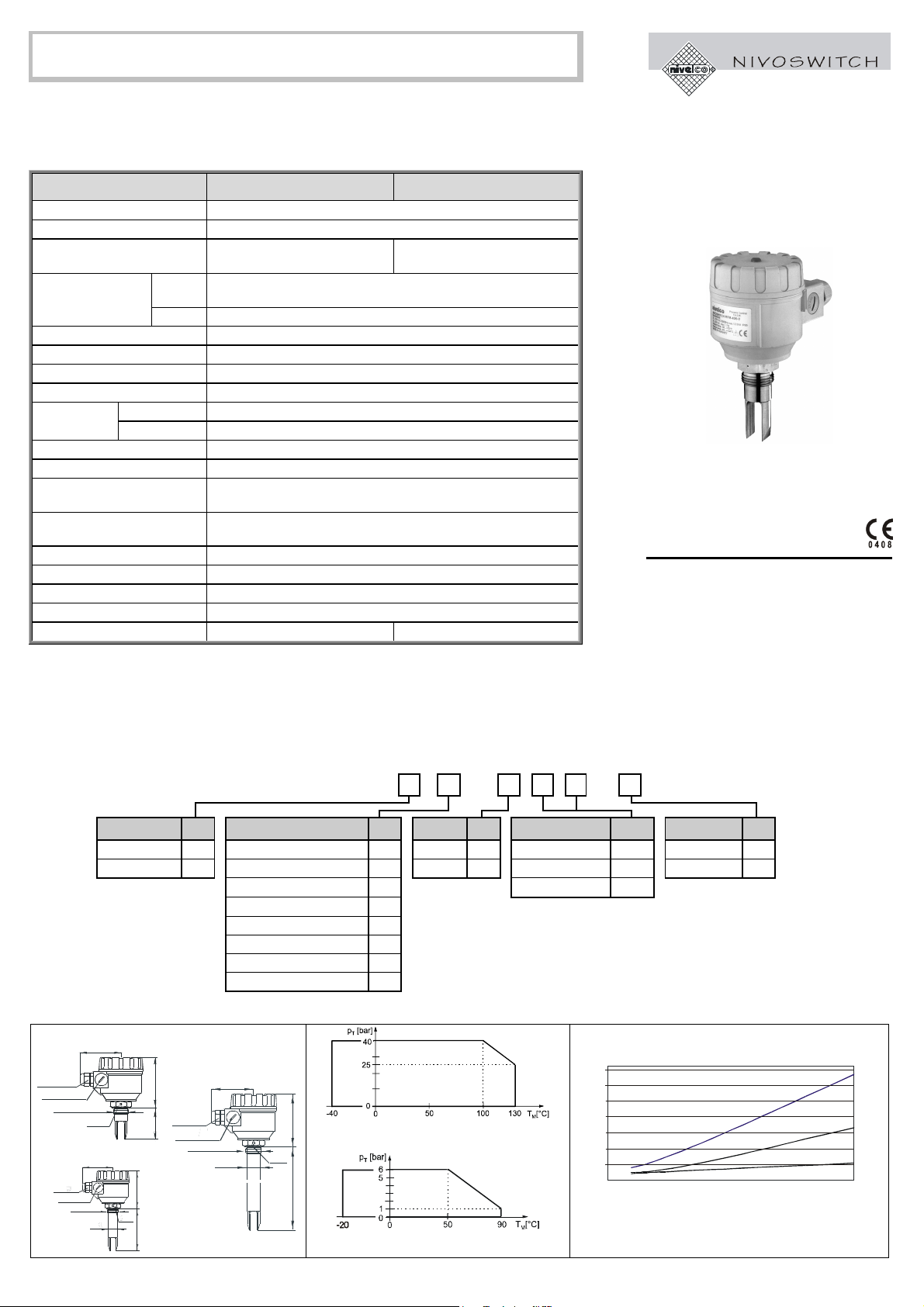

Medium -40 °C to +130 °C PP flange: -20 °C to +90 °C

ECTFE coated st.st. flange: -40 °C to +120 °C, for Derating see diagrams

Temperature ranges

Ambient -30 °C to +70 °C

Maximum pressure 40 bar (with PP flange 6 bar) See 2.4 Derating Diagrams

Probe length 69 to 3000 mm

Minimum medium density ≥0.7 kg/dm3

Maximum medium viscosity ≤10000 mm2/s (cSt)

Getting immersed ≤0.5 sec

Response time Getting free ≤1 sec See 2.4 Response Time Diagram

Operation mode indicator Bi-colour LED

Operation mode selection Switch for selection of HIGH or LOW fail safe mode

Output 1 or 2 SPDT relays

Relay 1: 250 V AC, 8 A, AC 1 Relay 2: 250 V AC, 6A, AC 1

Electric connections M 20 x 1.5 cable gland; ∅6 to 12 mm cables

(0.75 to 2.5 mm2wire cross section)

Supply voltage 20 ... 255 V AC and 20 ... 60 V DC

Consumption AC: 1.2 … 17 VA ; DC: < 3 W

Electrical protection Class I.

Ingress protection IP 67 (NEMA 6)

Weight 1.3 kg + 1.2 kg/m 0.95 kg + 1.2 kg/m

WARNING! Temperature difference between inner and outer surface of the ECTFE coated flanges must not exceed 60

°

C. If necessary,

insulate outer surface of the flange.

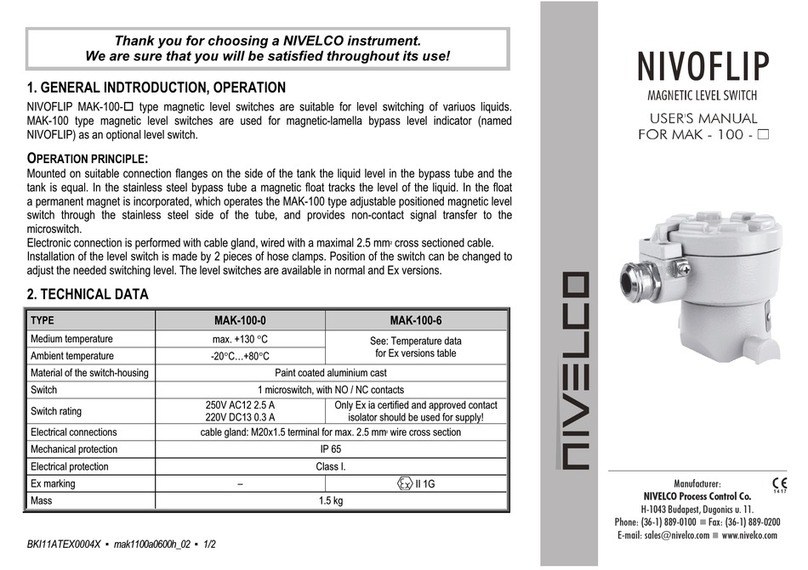

Vibrating fork level switches

Series: R-400 / R-500

USER’S MANUAL

2.1 ACCESSORIES

−User’s manual – Sealing 2 mm thick made of KLINGER OILIT (for 1” BSP process connection only)

−Warranty Card – Plug-in type, 3-pole terminal block (2 pcs for standard and 3 pcs for models with 2 relay)

−Declaration of conformity –Cable gland M 20 x 1.5 (2 pcs)

2.2 ORDER CODE

NIVOSWITCH R – –

FORK CODE CONNECTIONS CODE HOUSING CODE LENGTH CODE OUTPUT CODE

ECTFE coated D1” BSP thread MAlu. cast 4Short (69 mm) 00 1 Relay 0

Standard F1” NPT thread PPlastic 5Standard (125 mm) 01 2 Relay A

DIN DN50PN40 st.st flange G0.2 to 3 m 02…30

2” ANSI st.st. flange B

50A JIS st.st flange K

DIN DN50 PN16 PP flange F

2” ANSI PP flange A

50A JIS PP flange J

2.3 DIMENSIONS 2.4 Derating DIAGRAMS 2.5 RESPONSE TIME - MEDIUM VISCOSITY

Short model

2xM20x1.5

2 x NPT1/2"

1" BSP

1" NPT

89

S=41

69111

Standard model

89

2xM20x1.5

2 x NPT1/2"

1" BSP

1" NPT S=41

111

125

28

Pipe extended model

89

2xM20x1.5

2x NPT1/2"

1" BSP

1" NPT 28 S=41

111

0.2 ... 3 m

for all models (except PP flanged)

for models with Polypropylene flange

0

5

10

15

20

25

30

35

02000 4000 6000 8000 10000

fullyimmersed

halfimmersed

onlytheflatpartofthetinesimmersed

Kinematic viscosit

[cSt]

Response time

The test was performed using

silicone oils with different viscosity

Response time (when getting free) versus medium viscosity