Thank you for choosing a NIVELCO instrument.

We are sure that you will be satisfied throughout its use.

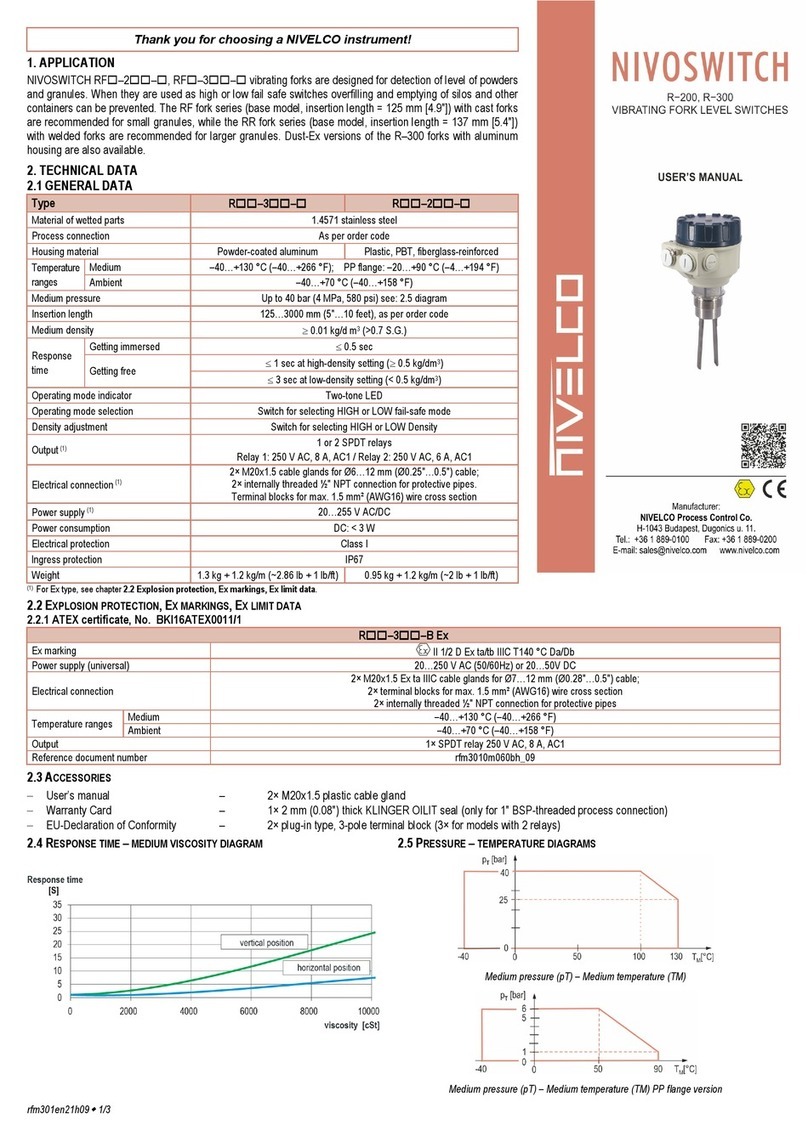

1. APPLICATION

The interaction of the magnetic float and the reed relays (incorporated in the protection tube) is the basis of the

NIVOPOINT magnetic float level switch series operation. They are suitable for level indication of normal and explosive

liquids, and can be used for level control tasks. The protecting tube contains a max. of 5 relays. Parts of the instrument are:

probe tube with magnetic float and housing containing the connection terminal.

The magnetic float moves alongside the protection tube tracking the level of the liquid and activating the reed relays.

As the float passes a relay it changes the output state of the relay which retains this state latching until the level decreases

and the float moves again along the respective relay to switch its state back.

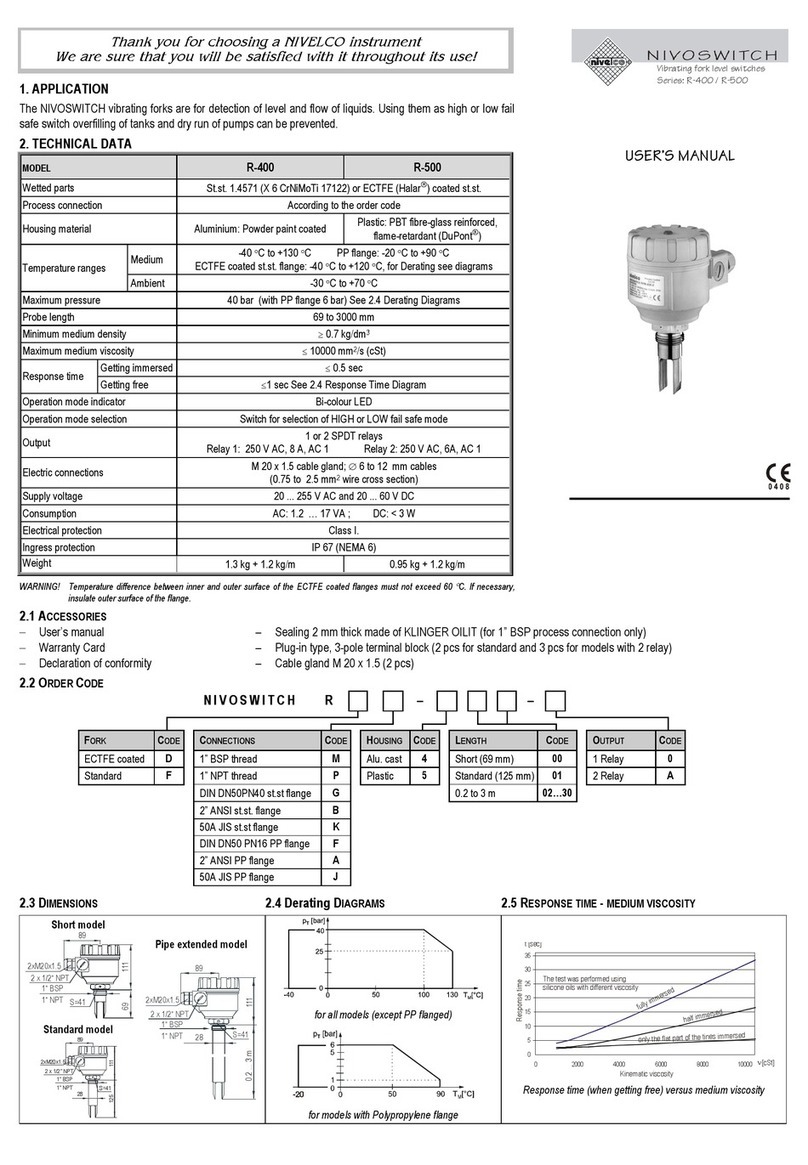

2. TECHNICAL DATA

2.1 GENERAL DATA

TYPE MR – MP– MR– Ex

Insertion length 0.25 m ... 3 m

Material of wetted parts Stainless steel

(DIN 1.4571 / BS 316Ti)

PVDF float / PFA coated

guiding tube

Stainless steel

(DIN 1.4571 / BS 316Ti)

Max. process pressure 2.5 MPa (25 bar) at +20 °C 0.3 MPa (3 bar) at +20 °C 2.5 MPa (25 bar) at +20 °C

Medium density min.0.8g/cm3min.0.5g/cm3min.0.6g/cm3min.0.8g/cm3

Nominal float dimensions* ∅52x59mm** ∅96 mm** ∅76 x 87 mm ∅52 x 59 mm

Medium temp. range -40 °C ... +150 °C -40 °C ... +80 °C

Ambient temp. range -40 °C ... +100 °C -40 °C ... +100 °C

See table of temperature

classes

Output 1 ... 5 pcs reed-switches, connecting one side of each, NO/NC

Switching rate 120 W / VA, 250 V AC/DC, 3 A /reed relay, max. 9 A

Switch differential < 10 mm

Distance of switches min. 110 mm

M20x1.5 for cables ∅6 to ∅12 mm M20x1.5 for cables ∅9.5 to

∅10 mm

Electrical connection

terminal, wire cross section: 0.5 to 2.5 mm2

Process connection 1” BSP, 2” BSP

1” NPT, 2” NPT

PP flange

DN 80, DN 100

1” BSP, 2” BSP

1” NPT, 2” NPT

Sealing material Klingerit 400 — Klingerit 400

Electrical protection Class I, Protecting cable 4 mm2

Ingress protection IP 65

Certificate for Ex versions —II 2 G EEx d IIC T3 …T6

Dimension of the hous. 116 x 80 x 65 mm 124 x 80 x 65 mm

Mass 0.4 kg + 0.3 kg/fm 0.45 kg + 0.3 kg/fm

* dimensions of the float depend on the order

** for the exact size of the float see dimensions

2.2 ADDITIONAL DATA FOR EX APPROVED MODELS

TEMPERATURE CLASS

CLASS T6 T5 T4 T3

Max. ambient temperature 80 °C 95°C 85°C 70°C

Max. medium temperature 85°C 100°C 135°C 150°C

N I V O P O I N T

USER’S MANUAL

1418

2.3 ACCESSORIES

−User’s Manual

−Certificate of Warranty

−Declaration of Conformity

−1 pc Gasket (for threaded versions)

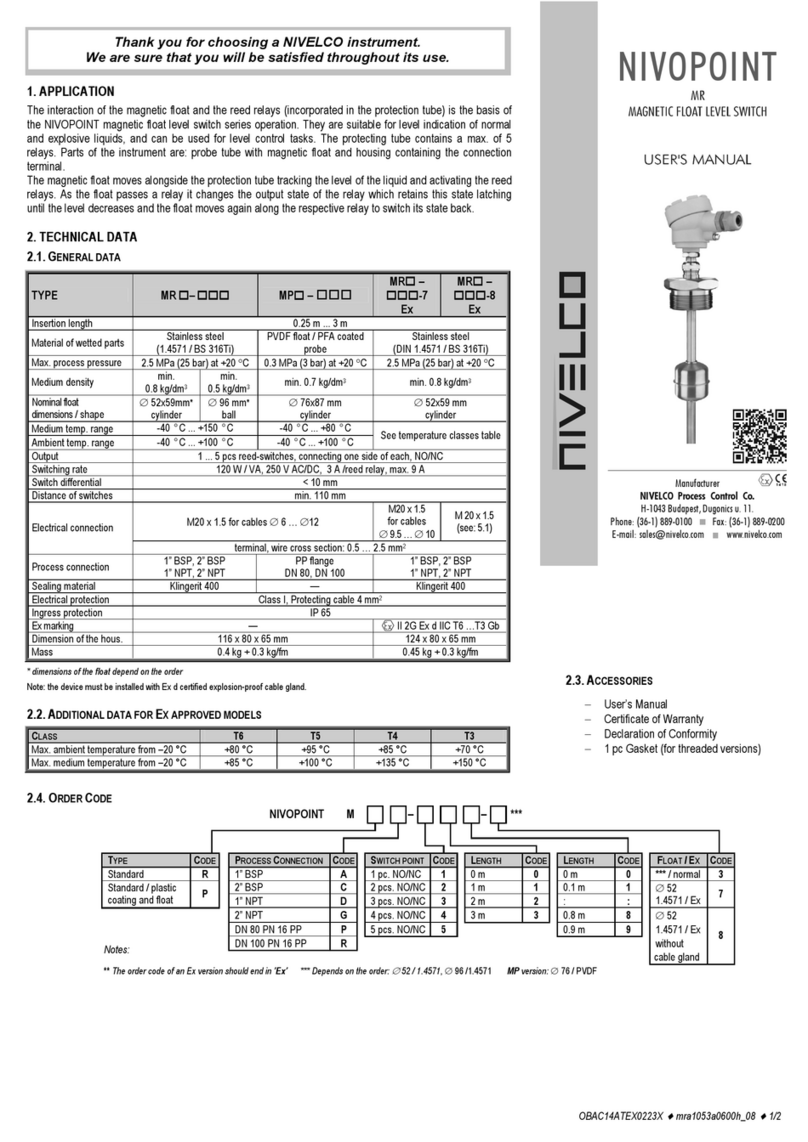

2.4 ORDER CODE

NIVOPOINT M – – ***

TYPE CODE CONNECTION CODE SWITCH POINT CODE LENGTH CODE LENGTH CODE FLOAT / EXCODE

Standard R1” BSP A1 pc. NO/NC 10 m 00 m 0**** / normal 3

2” BSP C2 pcs. NO/NC 21 m 10,1 m 1

Standard / plastic

coating and float P1” NPT D3 pcs. NO/NC 32 m 2::

∅52 1.4571

/ Ex 7

2” NPT G4 pcs. NO/NC 43 m 30,8 m 8

DN 80 PN 16 PP P5 pcs. NO/NC 50,9 m 9

Notes: DN 100 PN 16 PP R

*** The order code of an Ex version should end in ’Ex’ **** Depends on the order

∅

52/1.4571 MP version:

∅

76/PVDF,

∅

96/1.4571

BKI 02 ATEX 091X ♦mra1053a0600h_06♦2/1