rfm400en21h08 ♦ page 1

Thank you for choosing a NIVELCO instrument!

1. APPLICATION

NIVOSWITCH vibrating fork level switches are suitable for level detection of liquids. Mounted on pipes or tanks it

controls lling/emptying, also can generate fail-safe alarms providing overll- or dry run protection. The operating

principle involves an electronic circuit that induces vibration in the fork probe. When the medium reaches and

covers the fork, the vibration changes or stops. The fork will start vibrating freely again when the medium drops to

a level where it no longer touches the prongs. The electronics senses the change in the vibration and sends out

an output signal after a preset delay. The plastic-coated version is recommended for aggressive mediums, the

highly polished version is recommended for abrasive mediums. The ameproof version allows using the device

in Ex rated environments.

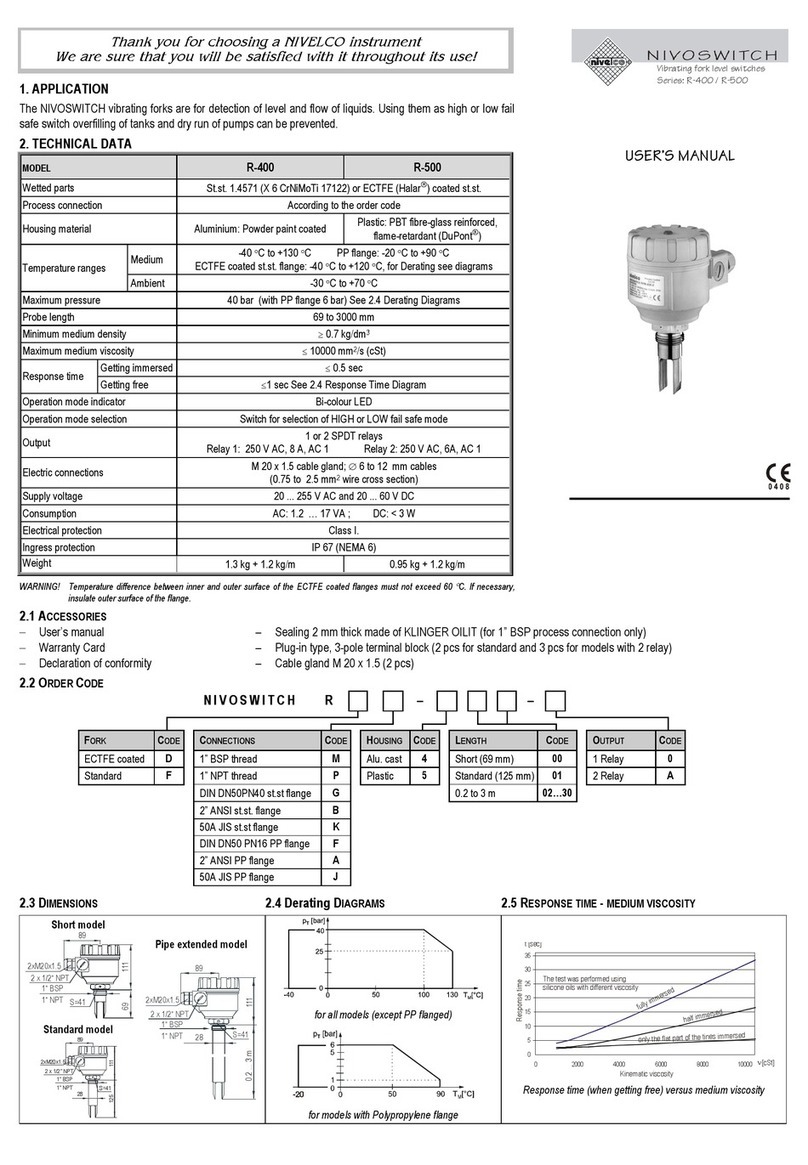

2. TECHNICAL DATA

2.1 GENERAL DATA

Type RM–4–Ex,

RN–4–Ex

RD–4–,

RF–4–,

RJ–4–

R–5

Material of wetted parts 1.4571 (316Ti) 1.4571(316Ti) / ECTFE / PFA-coating

Process connection As per order code

Housing material Powder-coated aluminum Plastic, PBT, ber-

glass-reinforced

Temperature

ranges

Medium

See: chapter 2.5.4

–40…+130 °C (–40…+266 °F);

PP ange: –20…+90 °C (–4…+194 °F);

*PFA-coated 1.4571 ange:

–40…+120 °C (–40…248 °F)

(see: diagram 2.3)

Ambient –40…+70 °C

(–40…+158 °F)

–30…+70 °C

(–22…+158 °F)

Medium pressure Up to 40 bar (4 MPa, 580 psi)

(see: 2.3 diagram)

Up to 40 bar (4 MPa, 580 psi) (with PP ange

6 bar [0.6 MPa, 87 psi]) (see: diagram 2.3)

Insertion length 69…3000 mm (2.7″…10 feet), as per order code

Medium density ≥0.7 kg/dm3 (>0.7 S.G.)

Medium viscosity ≤10000 mm2/s (cSt) (see diagram)

Response

time

Getting immersed ≤0.5 sec

Getting free ≤1 sec (see: diagram 2.4)

Operating mode indicator Two-tone LED

Operating mode selection Switch for selecting HIGH or LOW fail-safe mode

Output 1 or 2 SPDT relays

Relay 1: 250 V AC, 8 A, AC1 / Relay 2: 250 V AC, 6 A, AC1

Electrical connection See: chapter 2.5.

2× M20x1.5 cable glands for Ø6…12 mm

(Ø0.25″…0.5″) cable; 2× internally threaded

½″ NPT connection for protective pipes.

Terminal blocks for max. 1.5 mm² (AWG16) wire cross section

Power supply See: chapter 2.5. 20…255 V AC, 20…60 V DC

Power consumption <3 W

Electrical protection Class I

lngress protection IP67

Weight 2.1 kg + 1,2 kg/m

(~4.62 lb + 1 lb/ft)

1.3 kg + 1.2 kg/m

(~2.85 lb + 1 lb/ft)

0.95 kg + 1.2 kg/m

(~2 lb + 1 lb/ft)

* The temperature difference between inner and outer surface of the ECTFE or PFA-coated anges must not exceed +60 °C (+140 °F).

If necessary, insulate outer surface of the ange.

NIVOSWITCH

R–400, R–500

VIBRATING FORK LEVEL SWITCHES

Manufacturer:

Process Control Co.

H-1043 Budapest, Dugonics u. 11.

Tel.: +36 1 889-0100 Fax: 889-0200

E-mail: sales@nivelco.com www.nivelco.com

USER’S MANUAL

2.2 ACCESSORIES

– User’s manual

– Warranty Card

– EU-Declaration of Conformity

– 2× M20x1.5 plastic cable gland

(only for non-explosion-proof models)

– 1× 2 mm thick KLINGER OILIT sealing

(only for BSP-threaded process connection)

– 2× plug-in type, 3-pole terminal block

(3× for models with 2 relays)

PDF

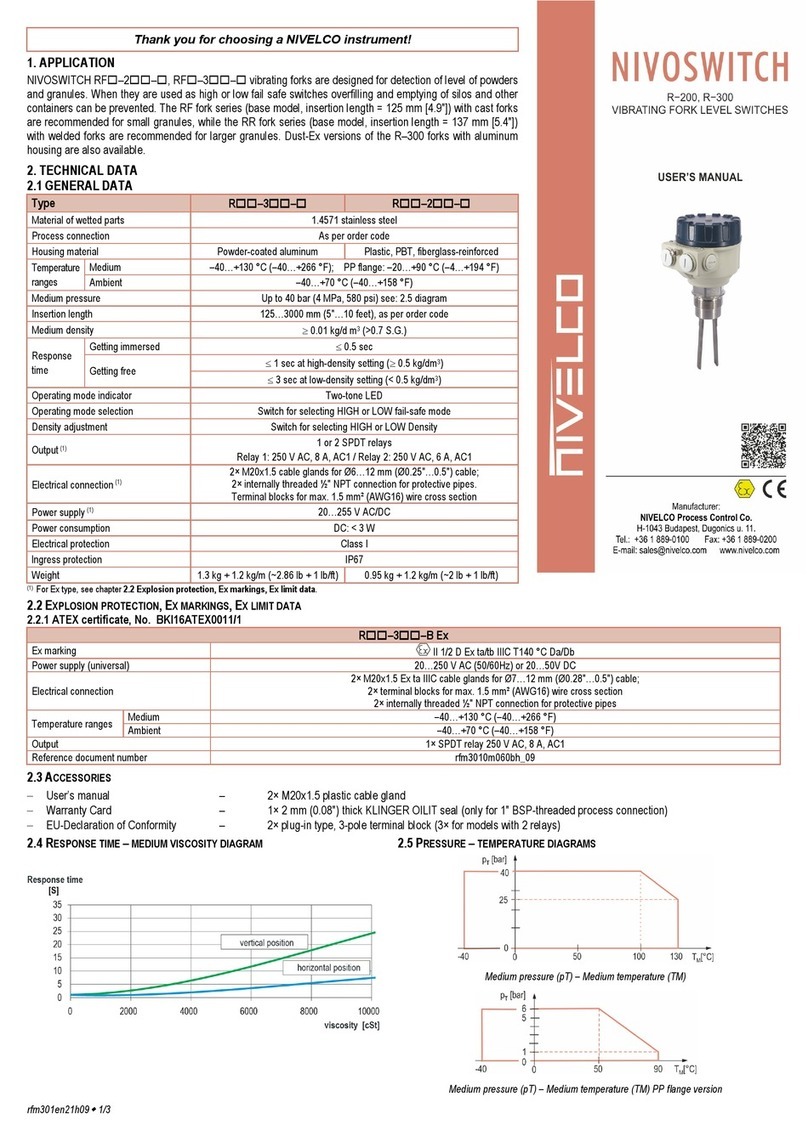

2.3 PRESSURE – TEMPERATURE DIAGRAMS

0

050

25

p[ ]

тbar

40

-40 100 130 T [°C]

p [bar]

T

0

1

50 90-20

5

6

0T [°C]

Medium pressure (pT) – Medium temperature (TM)Medium pressure (pT) – Medium temperature (TM) PP ange version

2.4 RESPONSE TIME – MEDIUM VISCOSITY DIAGRAM

0

5

10

15

20

25

30

35

0 2000 4000 6000 8000 10000

[S]

viscosity [cSt]

Response time

vertical position

horizontal position