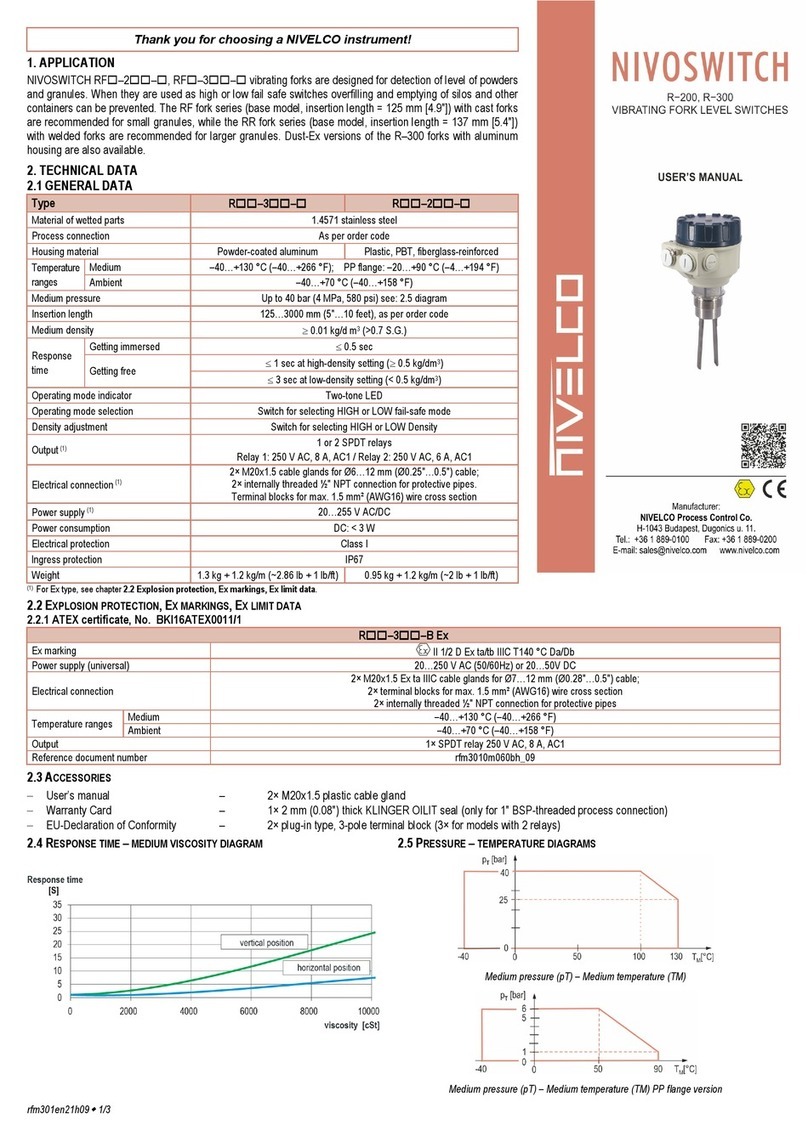

3. INSTALLATION

Prevent the device from any mechanical damage.

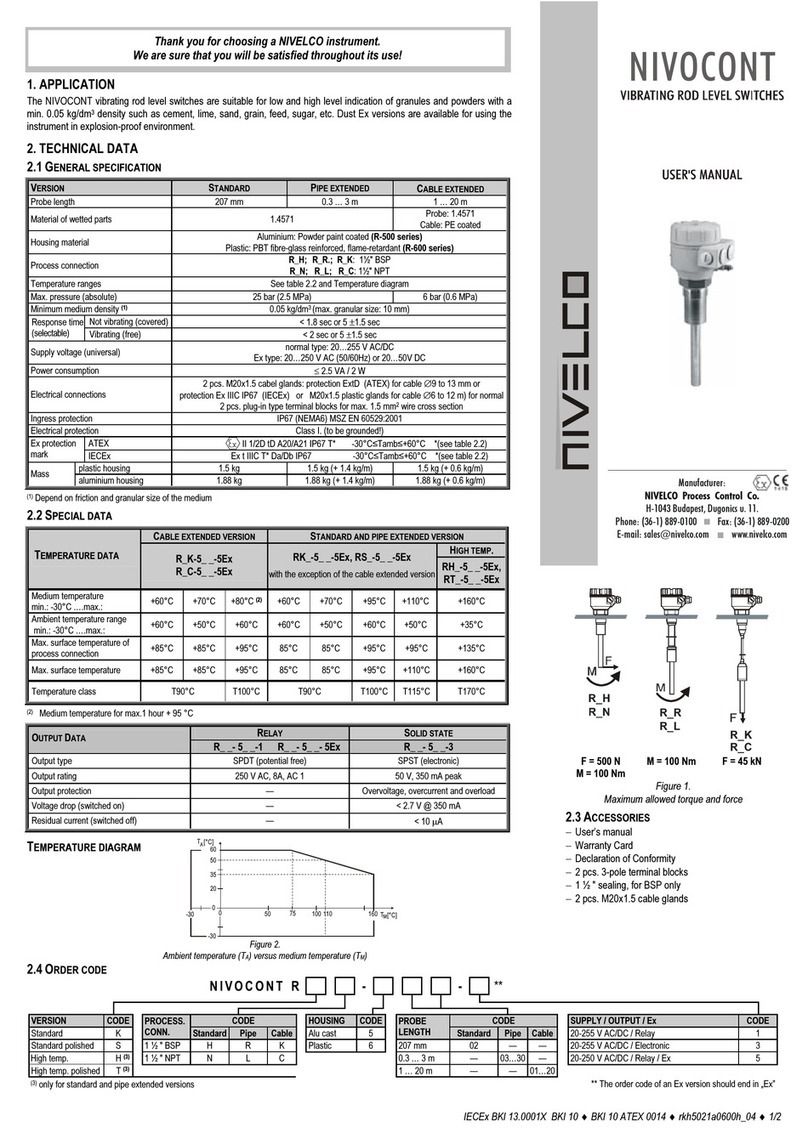

For positioning the fork-tines, use the marking on the hexagonal neck.

MARK

- Use a TEFLON (PTFE) tape to aid the position-

ing of the fork-tine.

- If the fork-tine position is irrelevant, use the

provided sealing ring

Do not use the housing, to screw the device into the process connection. Do it by

means of the sw = 41 mm hexagonal neck.

After screwing tight the device, the housing can be rotated (max. 300°), to adjust the

cable outlets to the required position.

Installation on liquids

In applications on liquids with

−low viscosity (without risk of material

remaining on the fork-tines) any of the

mounting shown beside is possible,

−high viscosity (due to risk of material

remaining on the fork-tines) only vertical

(top) mounting can be suggested.

In applications with side mounting take care

of the positioning mark.

Installation Options

Mounting threaded versions Critical distances (xmin= 5 mm)

Mountings to be avoided in case of

highly viscous liquids

Mounting in pipe fork-tines must be parallel to

the direction of flow

Installation on light, free flowing solids*

Vertical (top) mounting is the recommended mounting position. Side mounting is recom-

mended only where the fork-tines are easily freed from the process medium (ex.: through

gravity). In case of side mounting, the NIVOSWITCH must be mounted with the fork-tines

standing vertically (look for the positioning marks).

The short versions are not appli-

cable for solids

When determining the mounting

location, take into account the

caving or arching of the material

in the tank. It might be necessary

to install the device at an offset

level position relative to the

switching level actually required

Protect the probe from downfalling material !

Fork-tines should not be exposed to mechanical load.

SWITCHING POINT, SWITCH DIFFERENTIAL

(Values are for water at 25 °C)

Liquids: switching point as well as the switch differential slightly depends on liquid

density and mounting position.

Solids: switching point as well as the switch differential slightly depends on

material features and mounting position

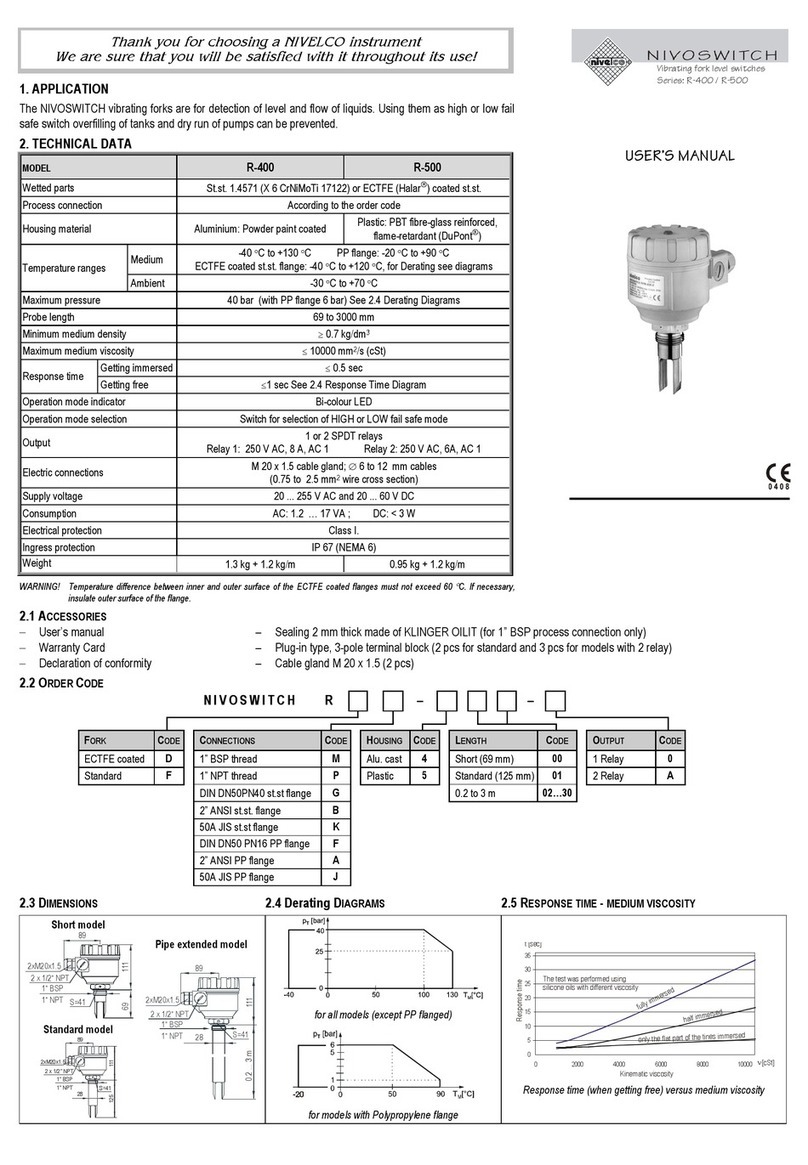

4. ELECTRICAL CONNECTIONS

Use 8 ... 15 mm outer diameter circular cables, and tighten cable glands as well as

housing cover after installation, to ensure an IP67 sealing.

For grounding the unit, either use the grounding screw terminal on the outside of the

housing or use the internal grounding screw terminal. AC with DC, or low voltage with line

cables must not be led in a common duct.

L1+

123

NPT 1/2"

6A/AC1

250VAC

8A/A C1

NPT 1/2"

Pg 16 Pg 16

Grounding

Output

Mains

Density Fail safe

mode

L1

+

789

456

23

7456 89

Status LED

Relay 1

Relay 2

250VAC

8A/AC1

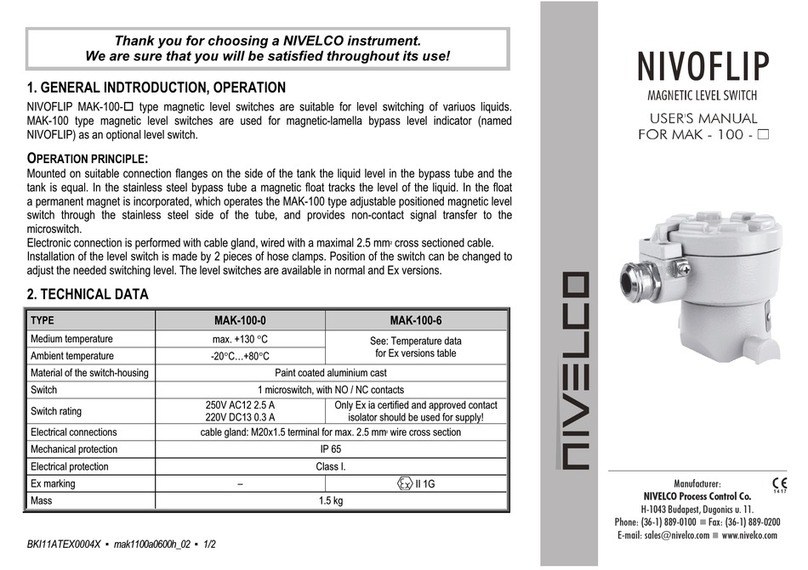

5. ADJUSTMENT

Suggested DENSITY switch settings are listed in the table below.

Liquids HIGH

LOW ρ< 0,5 kg/dm3

Free flowing solids

HIGH ρ≥0,5 kg/dm3

Before installing the unit, it is advisable to try operation on a small sample of the

product. Do not set a lower density than necessary, since because of greater sensitivity

this may result in indicating even small residues of material adhering to the probe.

OPERATING DIAGRAM

Power

supply Fork Fail safe

mode

Status

LED Output

HIGH RED

45 6 7 8 9

De-energised

Immersed LOW GREEN

45 6 78 9

Energised

HIGH GREEN

45 6 78 9

Energised

Yes

Free LOW RED

45 6 78 9

De-energised

No

Free

or

immersed

HIGH

or

LOW

NOT

LIT 45 6 78 9

De-energised

6. MAINTENANCE

The NIVOSWITCH does not require maintenance on a regular basis. In some instances,

however, the vibrating section may need to be cleaned from the deposited material. This

must be carried out carefully.

7. STORAGE CONDITIONS

Ambient temperature: -25 to +60 °C

Relative humidity: max. 98%

8. WARRANTY

We provide a warranty for the period of 2 (two) years.

All repairs under guarantee are performed in the Manufacturer's premises; the costs of

dismantling, reinstalling or transport are borne by the Customer.

Claims for guarantee are not valid in respect of failures due to abnormal usage, break-

age, disaster, or incompetent installation or usage.

rfm4000a0600h_02

September, 2001

Nivelco reserves the right to change technical specifications without notice.