Thank you for choosing a NIVELCO instrument!

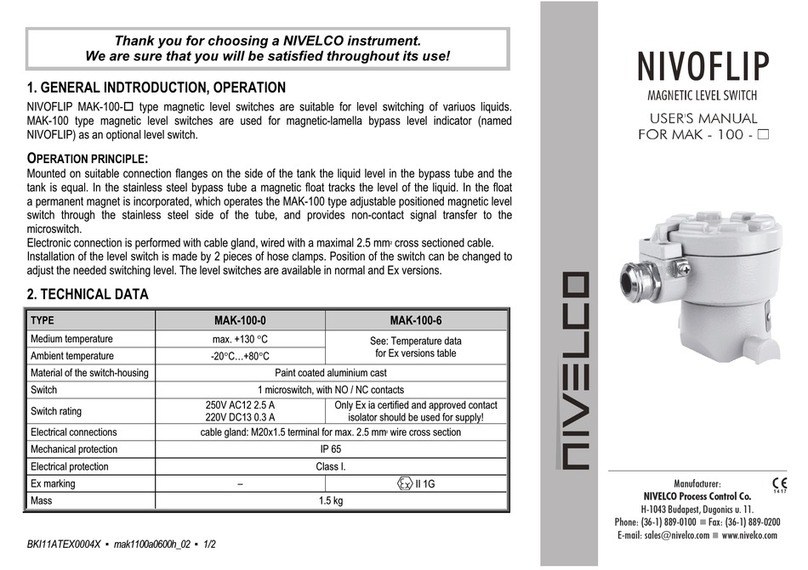

1. APPLICATION

NIVOFLIP MAK–200 type magnetic level switches are used for NIVOFLIP magnetic-lamella bypass level

indicator as an optional level switch.

OPERATING PRINCIPLE:

Mounted on suitable connection flanges on the side of the tank, the liquid level in the bypass tube and the

tank is equal. A magnetic float tracks the liquid's level in the stainless-steel bypass tube. A permanent magnet

is incorporated in the float, which operates the MAK–200 adjustable bistable reed switch through the stainless-

steel side of the tube and provides a non-contact signal to the microswitch.

The position of the switch can be changed to adjust the switching level. The distance between the two MAK–

200 units must be at least 60 mm (2.4″).

The cable is led through a cable gland. The maximum cross-section of the wire is 0.75 mm2(AWG18). The

level switch is attached with a hose clamp.

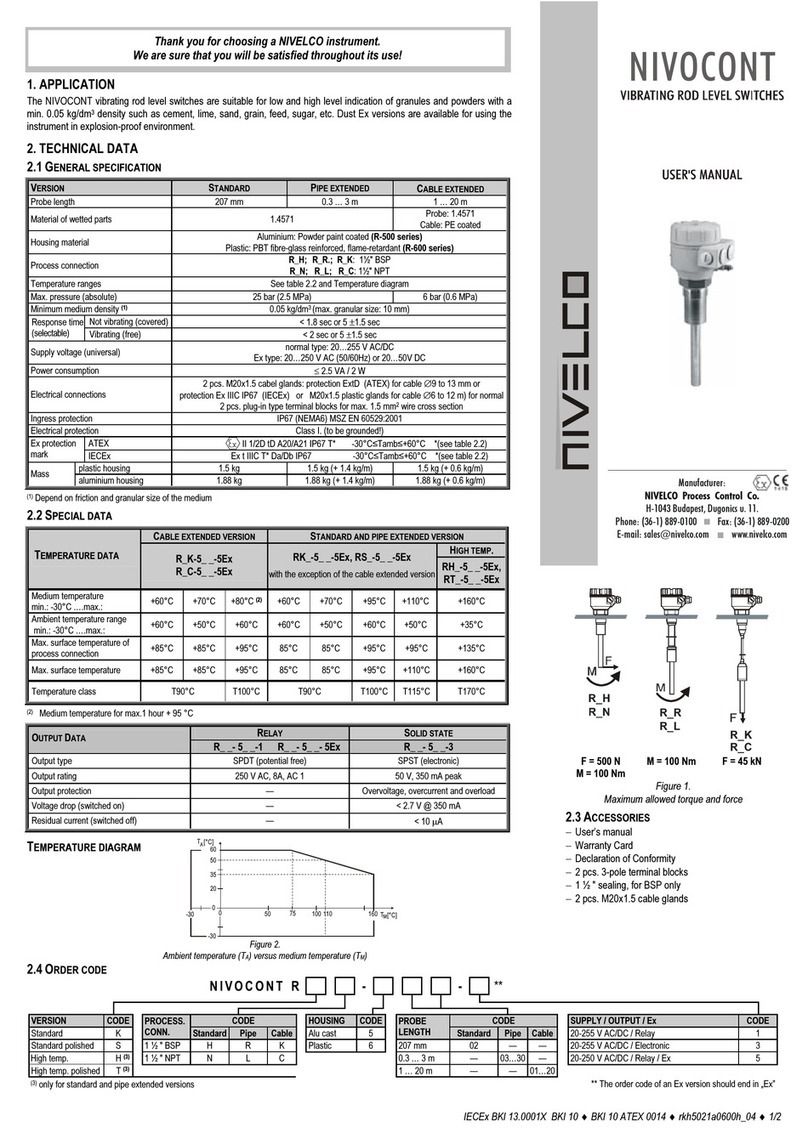

2. TECHNICAL DATA

MAK–2

Process temperature up to +130 °C (+266 °F)

Ambient temperature –25…+90 °C (−13…+194 °F)

Housing material Stainless steel (DIN 1.4571, AISI SS316Ti)

Bracket material Aluminum

Switch 1 bistable reed switch, with NO, NC contacts (1)

Switching hysteresis max. Δ20 mm (0.79″)

Switching data 120 W / VA; 250 V AC/DC; max. 3 A

Electrical connection M12 cable gland: cable diameter: Ø4…6 mm (Ø0.16…0.24"),

max 0.75 mm2(AWG18) wire cross section

Ingress protection IP65

Electrical protection Class II reinforced insulation

Overvoltage Protection Class II (degree of pollution: 2)

Weight ~0.15 kg (~0.33 lb)

(1) The contact type must be specified in the order code.

2.1 ACCESSORIES

User’s manual

Warranty card

EU Declaration of Conformity

Support bracket and hose clamps for 63 mm (2.48″) bypass

2.2 ORDER CODE

NIVOFLIP MAK –2 –

Output Code Electrical connection Code Type Code

1× bi-stable reed-switch NO 0 M12x1 connector 0 Normal 0

1× bi-stable reed-switch NC 1 Integrated cable 1

2.3 DIMENSIONS

3.MOUNTING 3.1 RECOMMENDED MOUNTING

Default start-up

Ensure that the switches are set to the correct position for the float position before starting up. If necessary, move

the float vertically up and down once by the switches before installing the float. It will set the switching positions to

the float's default (bottom).