Noaw NS220 Specification sheet

GRAVITY SLICERS

NS220 –NS250 –

NS250HD –NS300 –

NS300HD –NS350HD

Instructions for use and

maintenance

Edition March 2016

Installation, use and maintenance

1

LIST OF CONTENTS

Page

1. INTRODUCTION............................................................................................................................................................2

2. GENERAL INFORMATION ............................................................................................................................................ 2

2.1 SAFETY REGULATION ................................................................................................................................................. 2

2.2 GUARANTEE AND MANUFACTURER’S RESPONSIBILITY ...................................................................................... 3

2.3 THE USER’S OBLIGATIONS ........................................................................................................................................ 3

3. TECHNICAL CHARACTERISTICS.................................................................................................................................. 3

3.1 OVERAL SIZE................................................................................................................................................................ 3

3.2 PRODUCT THAT CAN BE SLICED............................................................................................................................... 4

3.3 PRODUCT THAT CANNOT BE SLICED ....................................................................................................................... 4

4. MAIN COMPONENTS ................................................................................................................................................... 4

5. INSTALLATION .............................................................................................................................................................5

5.1 UNPACKING AND ASSEMBLY.................................................................................................................................... 5

5.2 TESTING PRIOR TO OPERATION ............................................................................................................................... 5

6. CLEANING AND LUBRICATING ...................................................................................................................................5

6.1 PRODUCT TO BE USED ............................................................................................................................................... 5

6.2 CLEANING SHARPENING STONES............................................................................................................................ 5

6.3 LUBRICATION............................................................................................................................................................... 5

7. SHARPENING INSTRUCTION....................................................................................................................................... 6

8. TROUBLESHOOTING....................................................................................................................................................6

The manual is made up of 6 progressively numbered pages.

The contents are divided into progressively numbered paragraphs, if in any doubt about the contents and for any

further explanation contact the manufacturer or the authorised technical assistance, stating the paragraph

number of the pertinent subject

Installation, use and maintenance

2

1. INTRODUCTION

The purpose of this manual is to allow the user,

above all the direct user, to take every precaution

and arrange all human and material means

necessary for a safe and lengthy use of these

machines.

This manual must be given to the person who will

use and maintain the machines and this person will

keep the manual in a safe and dry place, ready to

be used.

The use and configurations of the machine are the

only ones allowed by the manufacturer; do not try to

use the machine differently from the indications.

The machines are to be used for cutting only food

products of the type and size indicated in the

following paragraphs.

The manufacturer declines all responsibility derived

from an improper use or use by personnel who has

not read and fully understood the contents of this

manual; changes and/or repairs carried out on

one’s own; the use of spare parts that are not

original or not specific for the type of machine.

For any explanation or doubts on the contents of

this manual, please contact immediately the

manufacturer or an authorised technical assistance

service.

2. GENERAL INFORMATION

The operating environment must have the following

characteristics:

-Temperature.............................. …..da -5°C a +40 °C

-Relative humidity......................................... max. 95%

The machine cannot be used in open areas and/or

exposed to atmospheric agents and in places with

fumes, smoke or corrosive and/or abrasive dust,

with the risk of fire or explosion and in any case

where the use of antideflagrating components are

prescribed.

The slicing machine must be used only by personnel

who has carefully read the contents of this manual.

The operators must be over 18 years of age, in

perfect mental and physical conditions, have the

right attitude and capacity (with the necessary

knowledge for manoeuvring and normal

maintenance of simple mechanical and electrical

components).

2.1 SAFETY REGULATION

SHARP KNIFE BLADE

To avoid serious personal injury

follow all the instructions in this

manual

Install the machine according to the

instructions in the paragraph “Installation”;

Install the machine so that it is far from

people who must not use it, especially

children;

Do not touch food while slicing. The user

should only touch the carriage handle or

carriage locking knob during slicing;

Do not be distracted while using the machine;

Do not wear loose clothing or open sleeves, if

necessary use headgear to keep hair out of

the way;

Do not let anyone come close to the machine

while in use;

Do not remove, cover or change the plates

that are on the machine and, if they are

damaged, replace them immediately;

Do not remove the protective devices and do

not change or exclude the mechanical

protective devices;

If the slicer jams, switch off and unplug

before removing obstruction;

Only slice permitted products; do not try to

slice any products that are not allowed;

The area around the machine, where the food

is laid and the floor where the operator works

must always be kept clean and dry;

Do not use the machine as a support surface

and do not place any object on it that does

not pertain to normal cutting operations;

Do not use the machine with electrical

connections of a “temporary” nature, with

temporary or non-insulated wires;

Periodically check the state of the mains

cable and the cable gland on the machine

body, when necessary have it replaced

without delay by qualified personnel;

Immediately stop the machine and call the

technical assistance service in the case of

anomalous function, suspicion of breakages,

incorrect movements, unusual noises, etc.;

Installation, use and maintenance

3

Before cleaning or carrying out any

maintenance, disconnect the machine from

the electric mains supply;

Always use gloves that are resistant to

cutting and tearing for the cleaning and

maintenance operations;

The goods to be cut must be placed on and

removed from the sliding plate with the

carriage in a retracted position and the

thickness regulating knob in the “O” position;

The use of accessories for cutting is not

allowed unless supplied by the maker

specifically for the machine;

For any exceptional maintenance (replacing

grindstones, blade, etc.) please contact the

manufacturer or qualified and authorized

personnel.

2.2 GUARANTEE AND MANUFACTURER’S

RESPONSIBILITY

The manufacturer declines all direct and indirect

responsibility deriving from:

-Not following the instructions in the manual;

-Persons using the machine who have not read

and understood the contents of this manual;

-Using the machine so that it does not conform

to specific regulations in force in the country of

installation;

-Unauthorised changes and/or repairs to the

machine;

-The use of accessories that are not supplied by

the manufacturer and spare parts that are not

original;

-The machine is not cleaned correctly with the

right product;

-Outstanding events.

2.3 THE USER’S OBLIGATIONS

The user must scrupulously observe the instructions

in this manual for the manufacturer’s guarantee to

be valid and particularly:

-Always respect the limits of the machine;

-Always carry out a constant and diligent

maintenance;

-Make sure the persons using the machine are

qualified and able to do so, including the fact

that they must have read this manual.

3. TECHNICAL CHARACTERISTICS

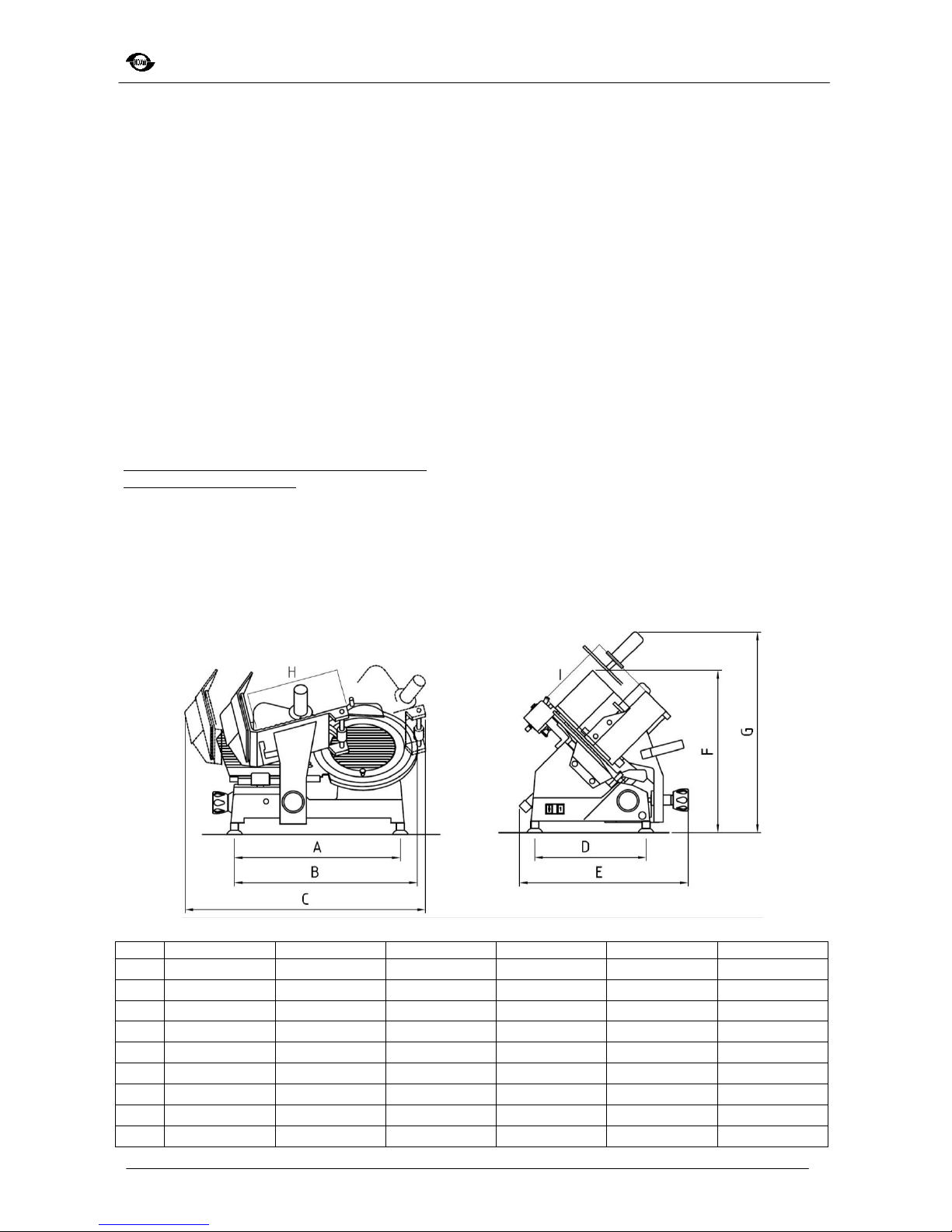

3.1 OVERAL SIZE

Rif.

NS220

NS250

NS250HD

NS300

NS300HD

NS350HD

A

410

410

480

480

540

540

B

480

480

530

530

600

620

C

590

590

630

630

680

760

D

320

320

320

320

370

370

E

430

430

440

440

560

560

F

370

400

450

450

520

530

G

370

410

460

460

570

600

H

195

230

230

230

250

310

I

190

230

230

230

290

330

Installation, use and maintenance

4

NS220

NS250

NS250HD

NS300

NS300HD

NS350HD

Blade diameter

mm

220

250

250

300

300

350

Height of cut

mm

155

170

170

220

220

250

Length of cut

mm

220

220

260

260

290

290

Slice thickness

mm

0-13

0-13

0-13

0-13

0-14

0-14

Blade speed

RPM

290

290

310

310

300

300

Motor power

Watt

180

180

250

250

370

370

Current

Amp

<2

<2

<2

<2

<2

<2

Voltage (AC)

Volt

230

230

230

230

230

230

Net weight

kg

14.5

16

19

20

29

36

3.2 PRODUCT THAT CAN BE SLICED

The following are products that can be sliced:

-All types of cold cuts (cooked, raw, smoked);

-Boneless meat (cooked or raw at a temperature

of no lower than +3 °C);

-Bread and cheeses (those that can be sliced,

such as Gruyere, Fontina, etc.).

3.3 PRODUCT THAT CANNOT BE SLICED

The following are products that cannot be sliced

because they could cause damage to people and

equipment:

-Frozen foods;

-Deep-frozen foods;

-Food with bones (meat and fish);

-Vegetables;

-Any other product that could be sliced but not

meant for consumption.

ATTENTION: Do not try to slice products that are not

allowed.

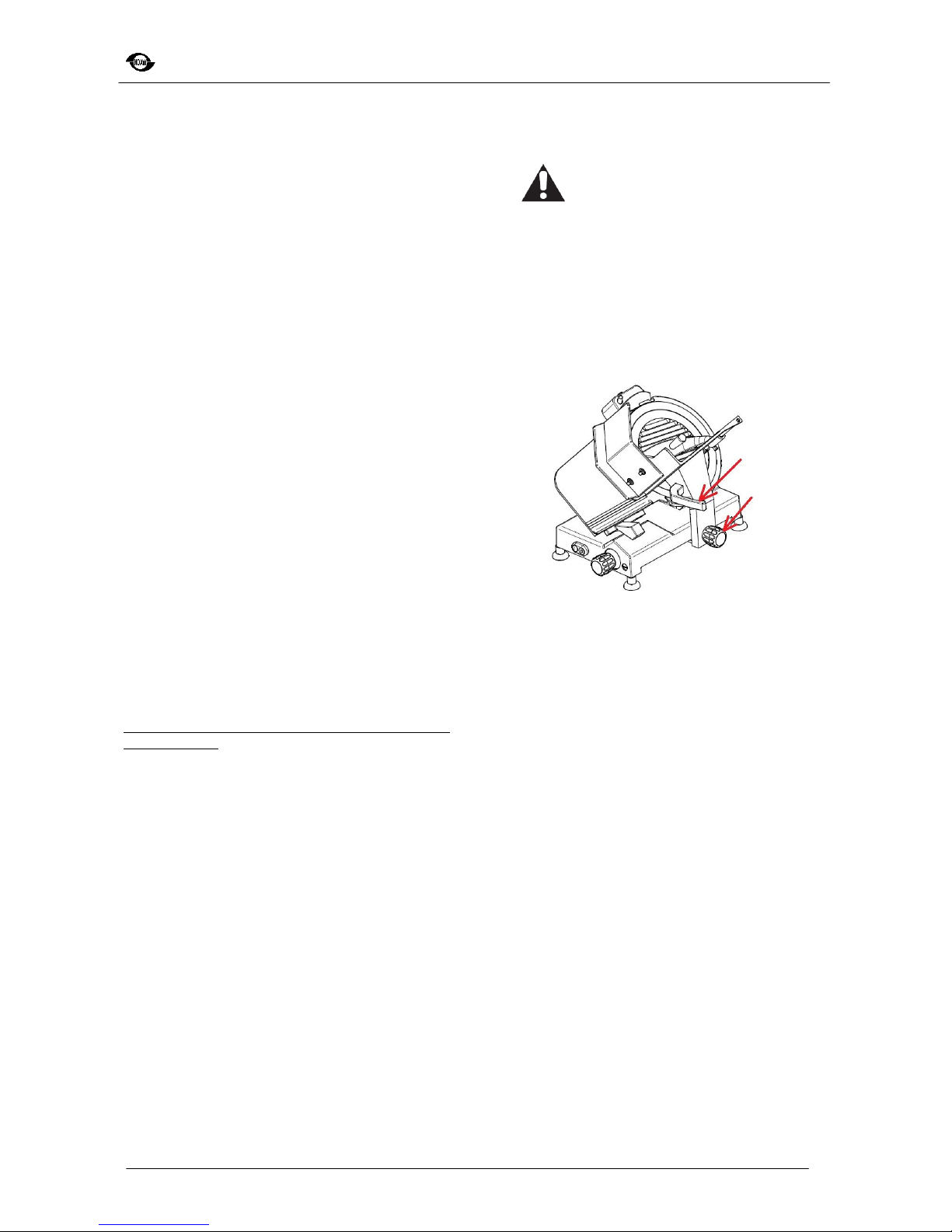

4. MAIN COMPONENTS

1. Feed cable

2. Identification plate, technical data and EC

marking

3. ON/OFF push button

4. Regulating knob for slice thickness

5. Food table

6. Food press handle

7. Food press

8. Rod

9. Slice deflector

10. Foot

11. Knob for table pushing

12. Table support

13. Table locking handle

14. Base

15. Blade cover

16. Blade guard ring

17. Sharpener cover

18. Blade

19. Safety guard

20. Gauge plate

21. Tie rod

Installation, use and maintenance

5

5. INSTALLATION

5.1 UNPACKING AND ASSEMBLY

1. When the slicer has been unpacked and removed from its shipping carton, it should be checked carefully for

any damage that may have occurred during shipment. Do not plug in the power cord or attempt to operate the

slicer prior to this examination. Any damage during shipment must be reported to the freight company and sales

agent within 3 days of receiving goods. No claims accepted after this period.

2. Carefully check all slicer components such as the product table, pusher, sharpener, thickness control knob,

etc., to make certain they move freely and that there are no obstructions. Turn the thickness control knob as far

right as possible. Lubricate the pusher slide bar (on the product table) and the square and round table support

rails (underside of slicer) with Food Grade Machine Oil / Grease. Vegetable oil should never be used. Vaseline

may be used if no suitable grease can be obtained.

3. Install the Slicer on a firm, level surface. The feet can be adjusted to prevent rocking on a slightly uneven

surface.

4. National Standards exist which outline position, spacing and ventilation requirements for appliance

installation. Please consult the relevant Standard for requirements on installation space. We recommend a

minimum, well ventilated air gap of 100mm. Please ensure a gap of at least 100mm is given or more as

specified in the local Standard.

5.2 TESTING PRIOR TO OPERATION

1. Make sure that the ON/OFF switch is in the OFF position, and the thickness control knob is turned as far to the

right as possible. In this way the gauge plate is in a position that the knife is not exposed during testing.

2. Plug power cord into correct electrical outlet, and ensure the mains cable does not cause a tripping hazard.

3. Turn the slicer ON and check for smooth knife rotation. Turn the slicer OFF.

4. Slide Product Table back and forth holding on to the Product Table Handle. If there is any rough operation or

obstruction, shut off, unplug power cord and call service for assistance.

6. CLEANING AND LUBRICATING

The machines must be properly cleaned at least once a day; if necessary even more.

If the machines have not been used for a while they must be cleaned before use as well.

6.1 PRODUCT TO BE USED

Only use hot water and a biodegradable detergent for dishes with a 7-8 PH, at a temperature of no lower than

30°C using a soft, spongy cloth and a semi-rigid nylon brush for the plate and the sharp food press.

WARNING: For cleaning the sharp areas of the plates, the food press and the blade, we recommend using

protective gloves.Rinse well with a lot of hot clean water and dry with a soft cloth or a spongy material.

Do not clean slicer with running water from a tap or hose, etcs.

6.2 CLEANING SHARPENING STONES

Each time the sharpener is used, the sharpening stones should be examined for cleanliness. Turn off slicer, close

the gauge plate, unplug power cord and remove sharpener. If there is evidence of fatty or metallic build-up in the

stones, they must be cleaned. Otherwise, they will not have the abrasive quality necessary to sharpen.

Clean stones with a semi-rigid nylon brush. Now replace the sharpener and lock in position.

Dirty Stones Cannot Sharpen!

IF THE SHARPENING STONES HAVE BECOME COATED WITH FOOD FATS OR METALLIC BUILD-UP,

THEY WILL NOT SHARPEN EFFECTIVELY.

REMOVING THE SHARPENER EXPOSES THE KNIFE. DO NOT LEAVE UN-ATTENDED.

6.3 LUBRICATION

Before lubricating, disconnect the machine from the power supply and turn the slice thickness regulator to zero.

Every week put a small amount of oil (a few drops) on the transversal sliding bar of the handgrip and on the

longitudinal sliding bar of the plate support inside the base of the machine.

Manually slide the groups and clean as necessary removing any excess oil.

ATTENTION: Use only Food Grade Machine Oil / Grease or Vaseline.

DON'T USE VEGETABLE OILS!

Installation, use and maintenance

6

7. SHARPENING INSTRUCTION

1. Switch OFF the power.

2. Unplug the slicer.

3. Turn the thickness control knob to the clockwise to place the gauge plate in the fully closed position.

4. Clean the knife completely. Always clean from the centre towards the outside edge of the knife. Never move

your hand towards the edge of the knife. Replace the centre plate knife guard.

5. Loosen the sharpener locking knob, raise and rotate the sharpener until the stones sit with one on each side

of the knife. Re-tighten the knob to hold the sharpener in its sharpening position.

6. Switch ON the power.

7. Press the sharpening stone push-button to bring the stone against the knife and hold it for five to 10

seconds and release.

8. Press the deburring stone pushbutton to bring the stone against the knife and hold it for two or three

seconds and release.

9. Switch OFF the power.

10. Return the sharpener to its stored position and lock in place.

11. Clean slicer before slicing product.

Your slicer is now sharpened, cleaned and sanitized-ready to use.

KNIFE SHOULD BE SHARPENED AT A MINIMUM ON A WEEKLY BASIS.

DO NOT SHARPEN A KNIFE THAT IS NOT CLEAN. YOU WILL DAMAGE THE SHARPENING STONES

AND BE UNABLE TO SHARPEN THE KNIFE.

8. TROUBLESHOOTING

Should your slicer fail to function properly, here are a few things you can check before calling FOR ASSISTANCE.

Product not slicing properly; thick and thin or irregular slices.

1. Is the knife sharp? If not, sharpen according to instructions. Remember, only sharpen a clean knife.

2. Does the product size exceed the capacity of the slicer? Too large a product may rub against the sharpener

assembly causing interference to normal slicing.

3. Is the product positioned correctly and held securely on product table? If not, product may move or rotate

during slicing operation resulting in partial or thick and thin slices.

4. Are all components held securely in place? A loose product table or pusher can cause inconsistent slices.

Knife not sharpening

1. Are sharpening procedures being followed exactly as explained in this manual?

2. Are sharpening stones clean? If not, clean according to instructions.

3. Is the knife clean? If coated with food fats, sharpener stones cannot sharpen. Clean per instructions.

4. Are sharpening stones making solid contact with the knife? If not, have a service engineer adjust them to the

proper height.

5. Are sharpening stones severely worn and not making contact with the knife? Are the sharpening stones

cracker or chipped? If so, have a service engineer replace and adjust the new stones to the proper position for

best sharpening results.

Electrical failure

1. Is slicer fully plugged into a properly grounded outlet? If properly connected, the red or white warning light

should be on when switch is in the ON position.

2. Inspect power cord. Has it been damaged, cutting off electrical flow? If so, call for service assistance to

replace the power cord.

3. Is ON/OFF switch in the ON position?

4. Are you getting electricity from the wall outlet? Check by plugging in another piece of equipment with the

same electrical requirements. Also, check circuit breaker or fuse.

5. If you are getting electrical power and your slicer is still not operating, contact service for assistance.

Thickness control knob not operating gauge plate

1. If the thickness control knob is not opening and closing the gauge plate properly, it is a sign that the internal

mechanism has suffered some loss of adjustment. Do not try to adjust the mechanism yourself. Call service for

assistance.

If correction of any of the above conditions does not result in a functional slicer, call service for assistance.

Other manuals for NS220

1

This manual suits for next models

5

Table of contents

Other Noaw Kitchen Appliance manuals

Noaw

Noaw 30E Specification sheet

Noaw

Noaw 250/14 Troubleshooting guide

Noaw

Noaw NS300M Troubleshooting guide

Noaw

Noaw 300/10H Troubleshooting guide

Noaw

Noaw NS220 User manual

Noaw

Noaw TWS Service manual

Noaw

Noaw 330/83 Troubleshooting guide

Noaw

Noaw LEADER 350G/LI Specification sheet

Noaw

Noaw A300 Specification sheet

Noaw

Noaw A300 Specification sheet