Noaw NS220 User manual

PROUDLY DISTRIBUTED BY

ROBAND AUSTRALIA PTY LTD

OPERATING INSTRUCTIONS

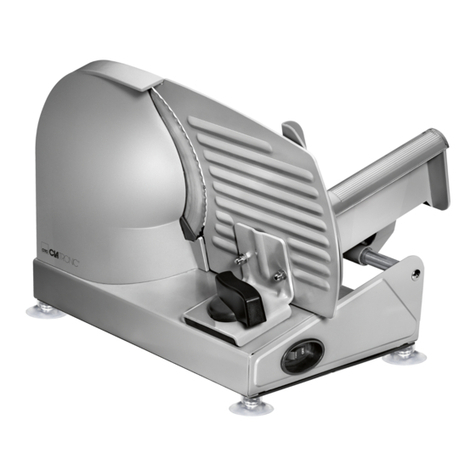

NOAW SLICERS

MODELS: NS220, NS250, NS300,Version 4

NS300HD & NS350HDVersion 3

Special Features:

Unique Safe Guard Safety System

Solid One-Piece Cast Aluminium Body

Motor-Saving Belt Drive System

Gravity Feed

These instructions cover the models of NOAW®Slicers listed above. Although

there are slight variances between models, the installation, operation, care and

maintenance procedure is the same for all.

Page

2

Roband Australia is a wholly Australian owned company, which has

been manufacturing quality commercial catering equipment for the

food service industry for more than 45 years. Roband products are

engineered and manufactured to the highest standards to provide

functionality, reliability and durability, and our quality products are

exported world-wide.

Included in the comprehensive Roband ranges are Grill Stations,

Toasters, Fryers, Milkshake Mixers, Rotisseries, Food Display

Cabinets and much more.

Roband Australia also acts as the Australian agents for Vitamix®

Blenders, NOAW®Meat Slicers, Ceado®Juicers and RYNO®Soup

Warmers and Rice Cookers.

In addition to a vast range of machines, Roband Australia has its own

line of commercial cookware and cutlery under the Robinox®brand

name.

For a complete set of brochures please contact your nearest

authorised dealer or contact Roband directly at our head office.

Roband Australia Pty Ltd

24 Middleton Road

CROMER

NSW 2099

Australia

Telephone: 61 – 2 – 9971 1788

Facsimile: 61 – 2 – 9971 1336

E-mail: [email protected]

Website: www.roband.com.au

© Copyright 2000 – Roband Australia Pty Ltd

All rights reserved. No part of this work may be reproduced or copied in any form or by any means,

electronic or mechanical, including photocopying or posting to a website, without the written permission of

the publisher. The material contained within this document is intended entirely for instructional purposes.

Page

3

CONTENTS

INTRODUCTION......................................................................................... 4

GENERAL PRECAUTIONS........................................................................ 4

PACKAGING .............................................................................................. 5

COMPLIANCE............................................................................................ 5

INSTALLATION.......................................................................................... 5

OPERATION............................................................................................... 6

SHARPENER USAGE.................................................................................................7

GENERAL SAFETY.................................................................................... 8

CLEANING, CARE & MAINTENANCE ...................................................... 9

Safety Blade Ring Guard: ............................................................................................9

Important Cleaning Notes: .........................................................................................10

TROUBLESHOOTING.............................................................................. 11

SPECIFICATIONS .................................................................................... 11

SAFE GUARD SAFETY SYSTEM............................................................ 12

NOTES...................................................................................................... 13

Warranty................................................................................................... 14

Page

4

INTRODUCTION

Congratulations on your purchase of this quality NOAW®product. With

proper care and management your new purchase will give you years of

trouble free service.

By reading these instructions carefully you can ensure that this machine is

used and maintained properly, helping your new investment to perform well

for you now, and to continue performing in the many years to come.

GENERAL PRECAUTIONS

This machine must only be operated by qualified person(s) who are fully

versed in the operating and safety instructions described in this manual.

Servicepersons should be instructed to familiarise themselves with any and

all safety instructions described in this manual prior to commencement of any

maintenance or service.

In the case of new personnel, training is to be provided in advance. These

machines should not be operated by persons (including children) with

reduced physical, sensory or mental capabilities, or lack of experience or

knowledge, unless they have been given supervision or instruction

concerning the safe use of the appliance by a person responsible for their

safety.

These machines are slicing units, and as with any commercial slicing unit

extra care is required. Always be careful when near an operating slicer, and

ensure that any risk to unwary customers or staff is minimised with additional

signage if necessary. Due to the obvious safety hazard it is recommended

that these units be kept out of reach of children.

The performance of this unit cannot be guaranteed for operational use

outside its design parameters

The machine should be disconnected from all power and the blade allowed

to stop before cleaning.

Roband will accept no liability if;

♦ Non-authorised personnel have tampered with the machine.

♦ The instructions in this manual have not been followed correctly.

♦ Non-original spare parts are used.

♦ The machine is not cleaned correctly, with the right product.

♦ There is any damage to the unit.

Page

5

PACKAGING

All care is taken when packing and Roband ensures that every unit is

functional and undamaged at the time of packaging.

The Package of this Slicer should include:

1) One Slicer (appropriate model)

2) This Manual

3) Packaging Materials

Any damage to the machine as a result of freight must be reported to the

Freight Company and to the agent responsible for the despatch of said unit

within three (3) days of receipt. No claims will be accepted or entertained

after this period.

COMPLIANCE

NOAW® products have been designed and manufactured to comply with

any and all specifications set out by the Australian Communications

Authority (ACA) in regards to Electromagnetic Compatibility. As testament

to such compliance these units bear the C-Tick symbol.

For further information contact the Australian Communications Authority, PO

Box 13112, Law Courts, Melbourne VIC 8010.

INSTALLATION

Remove all the packaging materials and tape, as well as any protective

plastic from the machine. Clean off any glue residue left over from the

protective plastic or tape.

Place the slicer on a firm, level surface in the required position. The feet can

be adjusted to prevent rocking on slightly uneven surfaces.

National Standards exist outlining the positioning, spacing and ventilation

requirements when installing new appliances. These Standards should be

consulted and new equipment should be installed accordingly. In any

situation where specifications allow a distance of less than 100mm we

would still recommend that a well-ventilated air gap of not less than 100mm

be maintained.

Ensure all guards are in place before connecting the power cord to a

standard 10 Amp power outlet. Observe all the safety warnings listed in

the section on safety on page 9.

Page

6

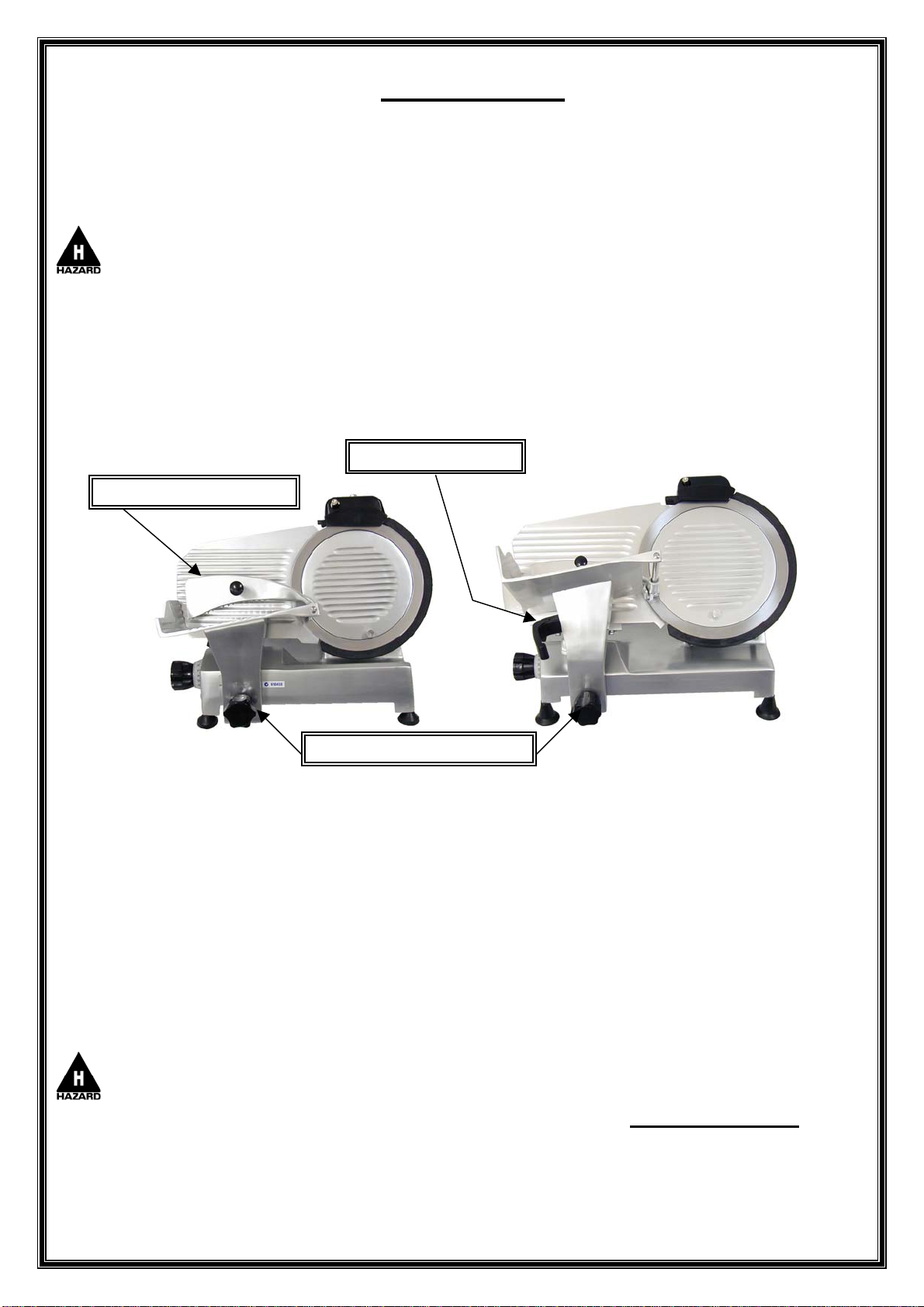

OPERATION

Place the product to be sliced on the sliding carriage. Position the meat

grip/product pusher on the outer end of the product. If the item is too long, place

the meat grip on top of product to hold it firmly in place. These slicers are of the

gravity feed type and do not require the operator to push the product towards the

blade. The product will progress towards the blade after each slice is taken.

Never push the product towards the blade with your hand.

Except where fitted with a carriage handle, the carriage securing knob is used to

move the sliding carriage during operation. Do not touch any other part of the

slicer or the product during operation.

Never try to operate the machine by pushing or pulling the handle on the Meat

Grip, use only the Carriage Knob and/or Carriage Handle.

The thickness adjustment allows you to vary the thickness of the slices from

“paper thin” to 16mm thick. To make thinner slices, turn the graduated thickness

adjusting knob to the right (clockwise). For thicker slices, turn the knob to the left

(anti-clockwise). The numbers on the knob will help you recall your desired

thickness for different products.

Once the product to be sliced is in position, and the thickness has been set,

switch the slicer "ON" and grasp the carriage handle or carriage securing knob.

Slide the carriage back and forth, letting the slices drop from the blade. The

shape of the blade will cause the slices to fall away behind it.

EXTREME CAUTION: the slicing of tomatoes (or other high water content

products) is not recommended. However, if the slicer is used to slice such

products, it is important to clean the back of the blade immediately after the

machine has stopped and been turned off and unplugged. Using a dry cloth or

sponge, carefully clean the back of the blade as you gently spin the blade with

the dry cloth or sponge. Never reach over the machine to clean the back of the

blade. Moisture in the motor as a result of slicing tomatoes and not wiping the

Carria

g

e Securin

g

Knob

Carria

g

e Handle

Hand

g

ri

p

/Meat Gri

p

Page

7

blade may cause the motor to fail. Motor failure caused by such moisture ingress

is not covered by warranty.

SHARPENER USAGE

To use the sharpening device, switch the machine off and rotate the thickness

adjusting knob fully to the “0” thickness position (clockwise). Unscrew the knob

just below the sharpening device. Lift the device up and over the blade so that

the sharpening stones straddle the blade. Use the knob to tighten the device in

place.

Switch the machine on and carefully push the stone that contacts the back of the

blade towards the blade using the pushing button, making contact with the blade

for about 5-10 seconds, depending on how blunt the blade is. This can be done

several times if required, but remember that the more often you sharpen the

blades the shorter the sharpening time required. Repeat the process for the

stone that contacts the front of the blade but only make contact for about 4 - 5

seconds. DO NOT TOUCH THE BLADE. Switch the machine off and replace

the sharpening device to its original position by reversing the procedure above.

Page

8

aSAFETY a

GENERAL SAFETY

This machine contains no user-serviceable parts. Roband Australia, one of

our agents, or a similarly qualified person(s) should carry out any and all

repairs. Any repair person(s) should be instructed to read the Safety

warnings within this manual before commencing work on these units.

Do not remove any covers that may be on the machine.

Always use the standard 10Amp power cord and plug provided. Ensure

that any damaged power cord is replaced before further use.

Never touch this machine without training and authorisation from your

supervisor.

The machine must be on a solid level support.

All guards must be in place before connecting to the power and switching

the machine on.

Always use the food pusher NOT YOUR HAND.

Never touch the rotating blade.

Always keep hands, arms, hair and loose clothing clear of all moving

parts.

Should the machine jam, switch off and unplug before removing the

obstruction.

Switch off and unplug the machine from the power source before cleaning,

sanitising or servicing.

Use only the attachments provided by the manufacturer.

Always set the thickness adjustment to the minimum thickness (zero on the

thickness adjusting knob) when the machine is not in use.

Page

9

CLEANING, CARE & MAINTENANCE

Attention to regular care and maintenance will ensure long and trouble free

operation of your slicer. Although scheduled servicing is not required we do

recommend you adopt a program of regular maintenance to ensure that the

slicer is clean and functional and to avoid inadvertently damaging the unit.

Daily cleaning should be considered mandatory for all equipment used in

the preparation of food. When dealing with Meat Slicers and the possibility

of cross contamination, these units should be cleaned before slicing each

new product. In order to ensure the slicer is cleaned properly and to avoid

damage, the instructions below should be followed.

Before cleaning ensure that the machine is switched off and unplugged,

and that the thickness adjustment is set to zero to prevent exposure of the

blade.

Use hot soapy water or denatured alcohol and a soft cloth/sponge for

cleaning, taking special care with the sharp blade.

It is important that the slicer is wiped down with a damp cloth or sponge,

NOT WET, to prevent any water (or denatured alcohol) ingress behind the

blade and into the motor. The blade guard may be removed to assist with

cleaning by undoing the knob at the rear of the machine opposite the

blade. Beware of the sharp blade and always replace the blade guard after

cleaning and re-tighten the knob.

Safety Blade Ring Guard:

In models containing a Safety Blade Ring Guard the black Safety Blade

Ring is a non-detachable part designed to prevent lacerations from an

unprotected blade during cleaning. Do not attempt to remove this essential

protective device.

Using a wire brush and then a damp sanitising cloth or sponge, clean the

small gap between the blade and the Ring Guard. The sponge/cloth can

be held over the Ring Guard and forced into the gap by pinching with your

thumb and forefinger (index finger). The cloth can then be run along the

length of the Ring Guard. Ensure that any sponge fibres are removed by

wiping them from the blade. A small “lick” from the sharpening stones will

also achieve this aim whilst also ensuring a sharp blade.

Page

10

Important Cleaning Notes:

• Do not use steel wool or steel wool soap pads on the slicer.

• Do not use other metal objects to scrape stubborn deposits of sliced

product from the slicer.

• Do not allow any food particles to remain on the slicer - clean at least

once a day.

• Do not clean this unit with the use of a water jet.

• Do not clean this unit, or any parts of this unit in a dishwasher.

• Never place the cord over the unit.

Page

11

TROUBLESHOOTING

If the slicer does not function check the following points before calling for

service.

The machine is plugged in correctly and the power switched on.

The power cord is whole and undamaged.

The power point is not faulty.

The switch is not broken.

The blade is sharp.

The tie rod is in securely.

SPECIFICATIONS

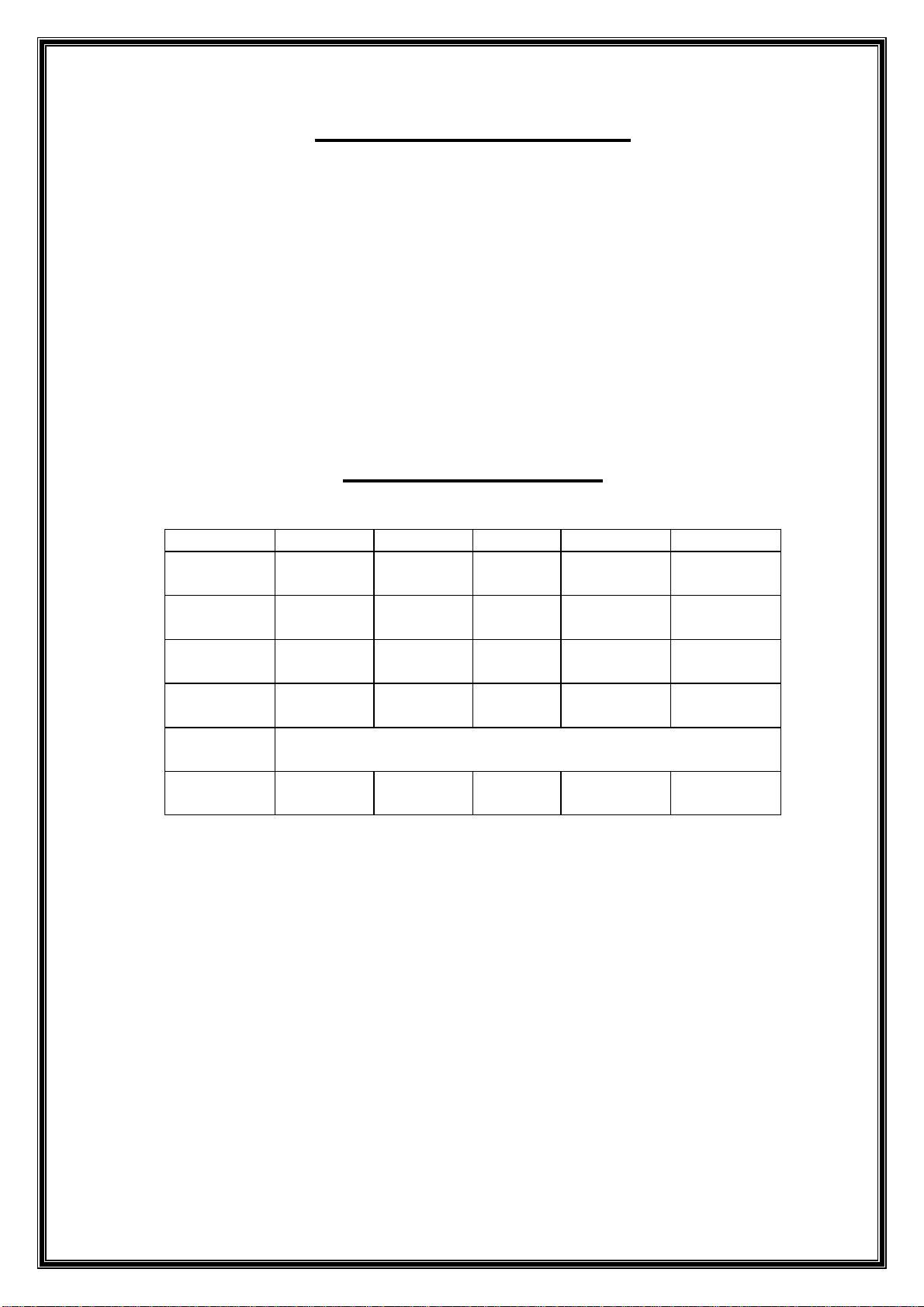

Model NS220 NS250 NS300 NS300HD NS350HD

Blade

diameter 220mm 250mm 300mm 300mm 350mm

Height of

cut 150mm 170mm 220mm 240mm 240mm

Carriage

movement 220mm 235mm 250mm 310mm 310mm

Slice

thickness 16mm 16mm 16mm 16mm 16mm

Power

source 220-240 Volts AC, 50 Hertz

Electrical

rating* 220W,

0.9A 220W,

0.9A 220W,

0.9A 370W,

1.6A 370W,

1.6A

* Motor Wattages quoted here are indicative of power under load and

will vary with heavier/lighter loads.

Constant Research & Development may necessitate machine

changes at any time.

Page

12

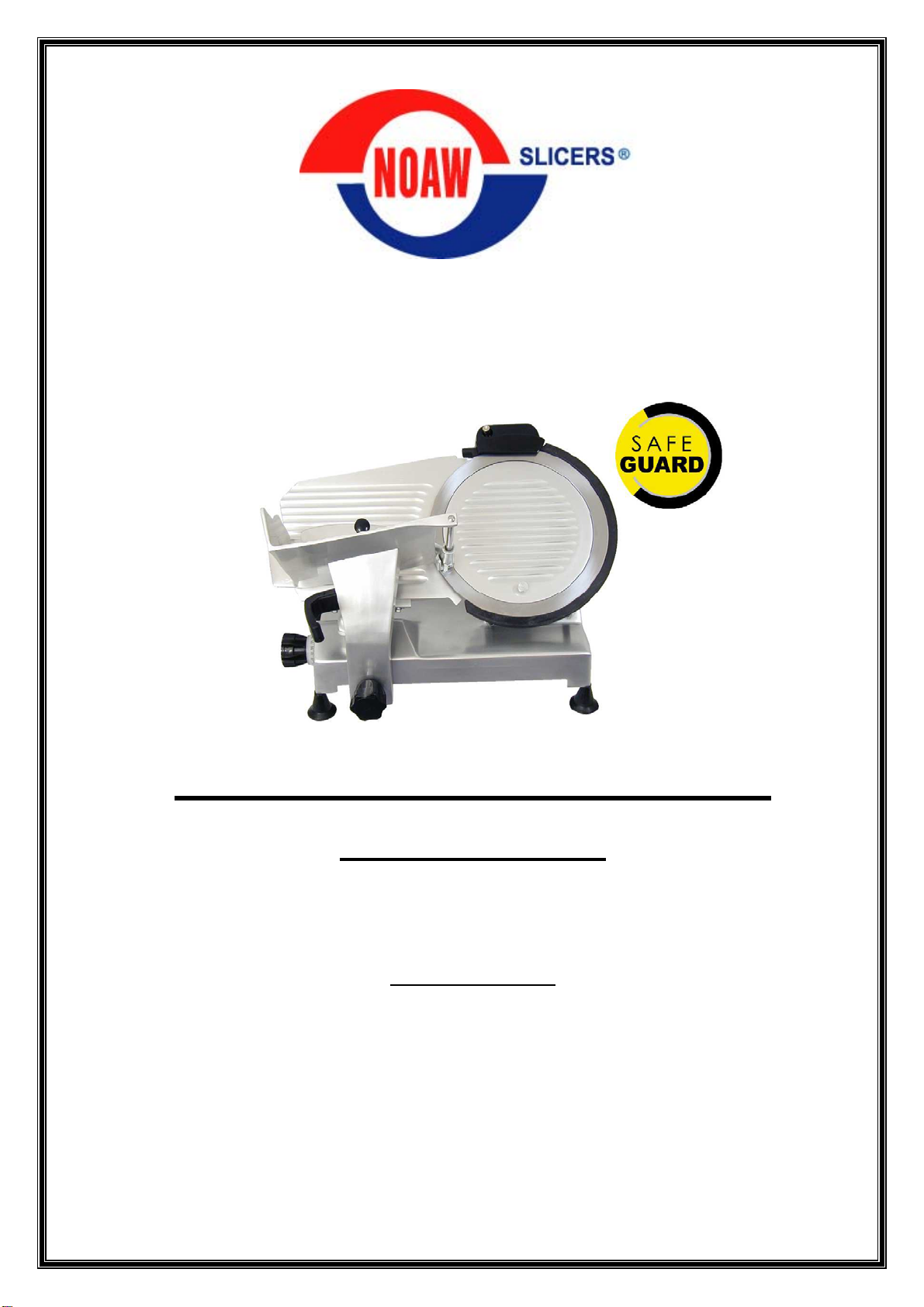

SAFE GUARD SAFETY SYSTEM

Exclusive to NOAW, the unique Safe Guard Safety System reduces the

potential for injury to the user, particularly during the cleaning of the unit,

and increases the longevity of the machines.

Workplace Safety has become a major issue with Slicers in recent years,

particularly given the potential for serious injury both in use and during

cleaning. The Safe Guard safety system has been developed by NOAW

with these issues in mind, and extensive research and development has

gone into producing a range of Slicers capable of meeting both the

productivity and OH&S demands of the commercial kitchen or workplace.

The non-removable glass-filled Nylon Safety Blade Ring Guard ensures

that cleaning is both simple and, more importantly, safe.

Additionally NOAW slicers have a safety cutout switch, which will prevent

the unit from operating when the cover on the front of the blade is removed

from the unit. Combine with this the shielding box around the electrical

switches to prevent minor splash ingress and you can see that NOAW

Slicers are built to last. In addition all NOAW Slicers are built with double

sealed bearings on the motor shaft AND an additional Blade Seal at the

rear of the blade to reduce the likelihood of liquid penetrating inside the

electrical segments of the motor

NOAW slicers also use a belt drive system to minimise any future repair

costs while maximising motor protection. Where gears will strip or burn out

the motor if the Slicer gets jammed, a belt will slip. The slipping action

allows the motor to continue turning somewhat, even when the blade has

jammed, reducing the potential for the motor to fail.

No other Slicer offers the NOAW Safe Guard (© 2002) safety system.

Models Containing the Safe Guard Safety System

NS220

NS250

NS300

NS300HD

NSA350

Page

13

NOTES

Record any preferred settings etc. here to act as a quick reference for other users.

Page

14

Warranty

Every care is taken to ensure that no defective equipment leaves our factory and all

goods manufactured by us are guaranteed against faulty workmanship and materials for

a period of 24 months from the date of purchase. Generally, all goods claimed under

this warranty must be returned to the factory or an authorised service agent, freight

prepaid, for inspection. Any part deemed to be defective will be replaced, however, no

claims will be entertained for parts damaged in transport, misused or modified in any

way without our approval. For machines that are not considered to be portable (e.g.

food bars, rotisseries, large hotplates and some bain maries), on site warranty service

will be provided in capital city metropolitan areas only. In all other locations, the

customer is responsible for all travelling time/service call costs and payment for this will

be required prior to the commencement of the repair. The labour costs to actually repair

the fault will be met by this company.

This company reserves the right to reject a claim for warranty if it is not completely

satisfied with the circumstances under which it occurred and any costs incurred for false

claims or faults due to incorrect usage etc. are the responsibility of the claimant. Under

no circumstances shall Roband Australia Pty Ltd or any subsidiary company or Agent

be liable for loss of profit or damage to other equipment and property.

Generally, authorised service agents are located in all areas, which have authorised

distribution dealers. For the name of your nearest Australian authorised service agent

please contact: ROBAND AUSTRALIA PTY LTD, Phone: (02) 9971 1788 Fax: (02)

9971 1336. All other countries please contact your selling agent.

WARRANTY REGISTRATION

Your new product is an important investment, and completion of the warranty

registration form is a vital first step in protecting your asset. We also encourage you to

register your product for the following reasons:

1. Registering your product will activate your free 2nd year warranty, making a total of

two years (24 months) full warranty, covering all parts and labour.

2. Completing the registration helps us provide more efficient warranty service in case

there is a problem with your appliance.

2. In the unlikely event of a product safety recall, or an important change to Australian

standards, we will be able to contact you immediately.

3. We like to know who buys our products as it helps us in better understanding and

servicing the needs of our customers.

To register your Warranty go to www.roband.com.au. Alternatively, please complete the

form and then detach and mail to: Roband Australia Pty Ltd, PO Box 500, Dee Why

NSW 2099.

To make a warranty claim you will be required to provide proof of purchase. Please ensure you retain your

recei

p

t for this

p

ur

p

ose.

Business Name…………………………………………………………………………………...

Contact Person……………………………………………………………………………………

Email address………………………………………………. Tel No……………………………

Address…………………………………………………………………………………………….

Model No…………………………………………..Serial No……………………………………

Name of Dealer where purchased……………………………… Purchase Date…………...

Type of Business (eg Café, Restaurant, Hotel, Takeaway, Institution such as hospital

nursing home, TAFE)…………………………………………………………………………….

What other equipment do you currently use?

!Water Boiling !Hot Water Urn !Meat Slicer !Grill

!Conveyor Toaster !Milkshake Mixer !Deep Fryer !Food Display Bar

!Griddle/Hotplate !Rice Cooker !Toaster - Refrigerated or Hot

!Pie Warmer !Soup Kettle !Blender

What factors MOST influenced your decision to purchase this product? (Tick up to 5)

!Ease of Use/Speed/Convenience !Specific Product Features !Brand Reputation

!Past Experience with the Brand !Quality/Reliability of unit !Warranty Terms

!Salesperson’s recommendation !Style Appearance !Price

!Advertisement (Print/In-Store Display)

!Other …………………………………………………………………….…..(please specify)

$ If you do not wish to receive any cashback offers, marketing or promotional material from us,

please tick this box.

******************************************************** cut along here **********************************************************************

Once the form is completed, cut along where indicated and mail to:

Roband Australia Pty Ltd

P.O. Box 500,

Dee Why,

NSW 2099

Thank you for completing this form. The information that you provide will be treated as confidential. If you

have any questions about how Roband handles your personal information, please contact us on (02) 9971-

1788 or by email: warra[email protected]. Alternatively, go to www.roband.com.au and follow the Privacy

Policy Statement link at the bottom of the page. Failure to submit this card will not diminish your warranty

rights.

ROBAND AUSTRALIA PTY LTD

If you would like information on any of our products, please call our Head Office on (02) 9971-1788

or go to www.roband.com.au.

Page

15

W

ARRANTY ACTIVATION CARD

Page

16

ROBAND AUSTRALIA PTY LTD

Authorised Distributor/Agent

Other manuals for NS220

1

This manual suits for next models

4

Table of contents

Other Noaw Kitchen Appliance manuals

Noaw

Noaw NS300M Troubleshooting guide

Noaw

Noaw A300 Specification sheet

Noaw

Noaw LEADER 350G/LI Specification sheet

Noaw

Noaw 250/14 Troubleshooting guide

Noaw

Noaw TWS Service manual

Noaw

Noaw 30E Specification sheet

Noaw

Noaw 330/83 Troubleshooting guide

Noaw

Noaw 300/10H Troubleshooting guide

Noaw

Noaw A300 Specification sheet

Noaw

Noaw A370G/L Specification sheet