Installation, use and maintenance NS300M –NS320M

2

1. INTRODUCTION

1.1 PURPOSE OF THE MANUAL

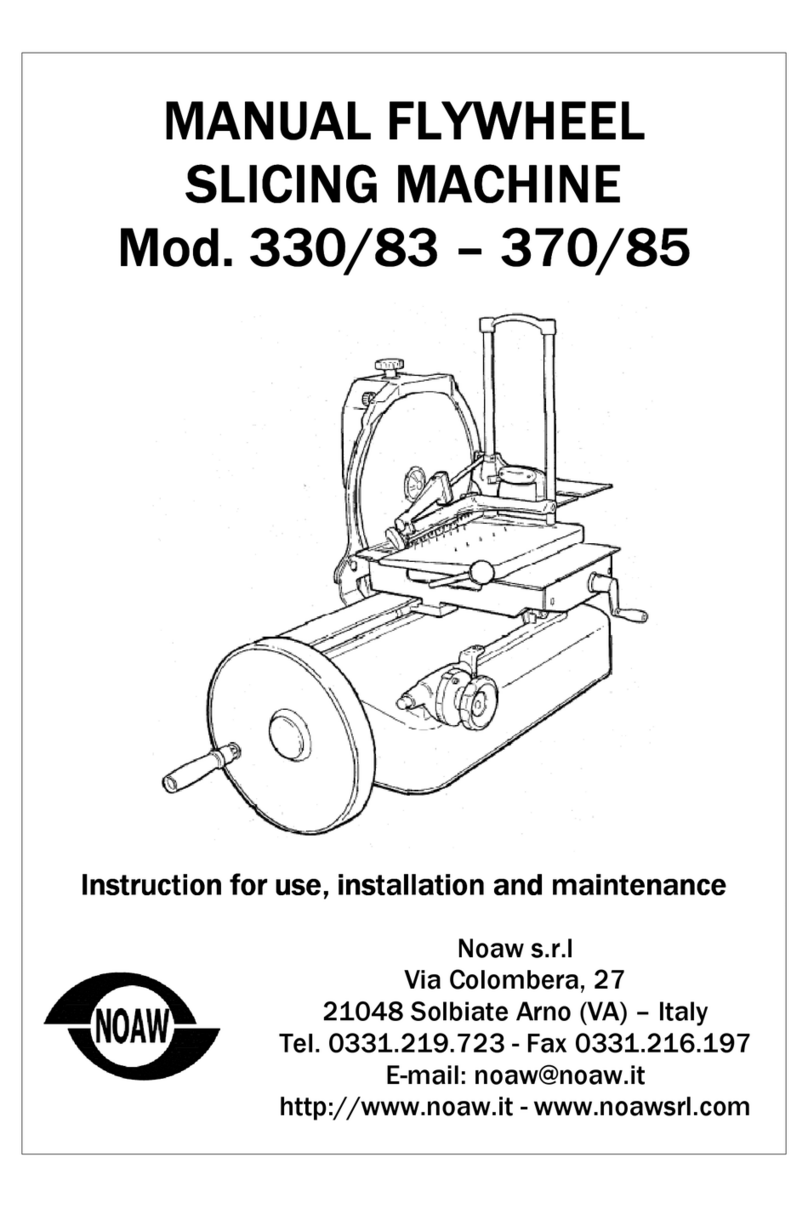

This publication contains all the information

necessary for the installation, use and maintenance

of the manual flywheel slicing machines to be used

for food, with circular blade, models NS300M and

NS320M.

The purpose of this manual is to allow the user,

above all the direct user, to take every precaution

and arrange all human and material means

necessary for a safe and lengthy use of these

machines.

1.2 KEEPING THE MANUAL

This manual must be given to the person who will

use and maintain the machines and this person will

keep the manual in a safe and dry place, ready to be

used.

We recommend that a copy be kept on file.

For any correspondence with the manufacturer or

authorised personnel, please refer to the

information on the plate and the machine serial

number.

The manual must be kept for the entire life of the

machine and in case of need (ex. any damage to

even a part of the manual that makes consulting it

difficult) the user must acquire a new copy

exclusively from the manufacturer.

The user must let the manufacturer know the

address of any new owner of the machine.

1.3 USE OF THE MACHINE

The use and configurations of the machine are the

only ones allowed by the manufacturer; do not try to

use the machine differently from the indications.

The machines are to be used for cutting only food

products of the type and size indicated in the

following paragraphs.

The manufacturer declines all responsibility derived

from an improper use or use by personnel who has

not read and fully understood the contents of this

manual; changes and/or repairs carried out on one’s

own; the use of spare parts that are not original or

not specific for the type of machine.

For any explanation or doubts on the contents of this

manual, please contact immediately the

manufacturer or an authorised technical assistance

service and quote the paragraph number of the

required subject.

2. GENERAL INFORMATION

2.1 MACHINE LIMITS, SAFETY REGULATIONS

The machine has been designed and made to slice

food products of the type and size as indicated in

paragraphs 3.1, 3.2, and 3.4.

Environmental conditions for using the machine

The operating environment must have the following

characteristics:

-Temperature.............................. ….da -5°C a +40 °C

-Relative humidity......................................... max. 95%

The machine cannot be used in open areas and/or

exposed to atmospheric agents and in places with

fumes, smoke or corrosive and/or abrasive dust,

with the risk of fire or explosion and in any case

where the use of antideflagrating components are

prescribed.

General safety regulations

The slicing machine must be used only by personnel

who has carefully read the contents of this manual.

The operators must be over 18 years of age, in

perfect mental and physical conditions, have the

right attitude and capacity (with the necessary

knowledge for manoeuvring and normal

maintenance of simple mechanical and electrical

components).

For a safe use of the machine follow the

instructions below:

▪Install the machine according to the

instructions in the paragraph “Installation”;

▪Install the machine so that it is far from

people who must not use it, especially

children;

▪Do not be distracted while using the machine;

▪Do not wear loose clothing or open sleeves, if

necessary, use headgear to keep hair out of

the way;

▪Do not let anyone come close to the machine

while in use;

▪Do not remove, cover or change the plates

that are on the machine and, if they are

damaged, replace them immediately;

▪Do not remove the protective devices and do

not change or exclude the mechanical

protective devices;