Noaw LEADER 350G/LI Specification sheet

21048 SOLBIATE ARNO (VA)

Via Colombera, 27

Tel. 0 1.219.72

Fax 0 1.216.197

E-mail: noaw@noaw.it

http://www.noaw.it -

www.noawsrl.com

Slicers LEADER

50- 70G/LI

GRAVITY FEED

TRANSMISSION GEAR

Instructions for use and

maintenance

Use and maintenance

1

Slicers LEADER

Ø 50/ Ø 70

GRAVITY FEED

GEAR TRANSMISSION

INSTRUCTION HANDBOOK

Edition November 2010

Use and maintenance

2

LIST OF CONTENTS

Page

1. INTRODUCTION..................................................................................................

1.1 Purpose of the manual...............................................................................................

1.2 Keeping the manual ...................................................................................................

1. Use of the machine.....................................................................................................

2. GENERAL INFORMATION..................................................................................4

2.1 Machine limits, safety regulations.............................................................................4

2.2 Guarantee and manufacturer’s responsibility...........................................................5

2. The user’s obligations................................................................................................5

2.4 Markings - Plates........................................................................................................5

. TECHNICAL CHARACTERISTICS......................................................................6

.1 Data sheets.................................................................................................................6

.2 Furnished items and accessories..............................................................................7

. Products that can be sliced .......................................................................................7

.4 Products that cannot be sliced..................................................................................7

4. DESCRIPTION.....................................................................................................8

4.1 Unpacking...................................................................................................................8

4.2 Main components.....................................................................................................10

4. General description..................................................................................................11

5. INSTALLATION..................................................................................................12

5.1. Installing the machine.............................................................................................12

5.2. Command description.............................................................................................12

5. Electrical connection................................................................................................12

5.4 Checking direction of blade rotation (only for machine with three phase motors)

.........................................................................................................................................1

6. USING THE SLICING MACHINE ......................................................................1

6.1 Loading the goods on the plate and cutting ...........................................................1

6.2 Cleaning the slicing machine ..................................................................................15

7. MAINTENANCE AND REPAIRS........................................................................19

7.1 General information .................................................................................................19

7.2 Sharpening the blade...............................................................................................19

7. . Lubricating the guide bars of the carriage with arm and food table support

(weekly)...........................................................................................................................21

7.4 Lubricating the transversal guide rods of the table and food press (weekly) ......21

8. LOCATING AND ELIMINATING FAILURES .....................................................22

9. CIRCUIT DIAGRAM...........................................................................................2

10. DISMANTLING THE SLICING MACHINE.......................................................25

Use and maintenance

3

1. INTRODUCTION

1.1 Purpose of the manual

This publication contains all the information necessary for the use and maintenance of

“LEADER” slicing machines ith gear transmission to be used for food, ith circular blade,

models Ø 350 mm and Ø 370 mm.

The purpose of this manual is to allo the user, above all the direct user, to take every

precaution and arrange all human and material means necessary for a safe and lengthy use

of these machines.

1.2 Keeping the manual

This manual must be given to the person ho ill use and maintain the machines and this

person ill keep the manual in a safe and dry place, ready to be used. We recommend that a

copy be kept on file.

For any correspondence ith the maker or authorized personnel, please refer to the

information on the plate and the machine serial number.

The manual must be kept for the entire life of the machine and in case of need (ex. any

damage to even a part of the manual that makes consulting it difficult) the user must acquire

a ne copy exclusively from the maker.

The user must let the manufacturer kno the address of any ne o ner of the machine.

Note: The terms Front, Back, Right and Left used in this manual refer to the machine as seen

from the operator’s side in normal orking conditions.

1. Use of the machine

The use and configurations of the machine are the only ones allo ed by the manufacturer; do

not try to use the machine differently from the indications. The indicated use of the machine is

only valid for machines ith a complete structural, mechanical and system efficiency.

The machines are to be used for cutting only food products of the type and size indicated in

this manual.

The maker declines all responsibility derived from an improper use or use by untrained

personnel, changes and/or repairs carried out on one’s o n or by unauthorized personnel,

the use of spare parts that are not original or not specific for the type of machine.

For any explanation or doubts on the contents of this manual, please contact

immediately the manufacturer or an authorized technical assistance service and quote

the paragraph number of the required subject.

Use and maintenance

4

2. GENERAL INFORMATION

2.1 Machine limits, safety regulations

The machine has been designed and made to slice food products, ith a continuous service,

of the type and size as indicated in paragraphs 3.2, 3.3 e 3.4.

2.1.1 Environmental conditions for using the machine

- Temperature from -5°C to +40°C

- Humidity max. 95%

The slicer cannot be used in opened places and/or atmospheric agents. It cannot be used in

rooms ith steams, fumes or corrosive and/or abrasive dusts ith fire or explosion risk and

every here they are used anti-deflagration components.

2.1.2 General safety regulations

The slicing machine must be used only by an adequately trained person ho has carefully

read the contents of this manual. The operators must be over 18 years of age, in perfect

mental-physical conditions, have the right attitude and capacity and necessary kno ledge for

manouevering and normal maintenance of simple mechanical and electrical components.

For a better use of the machine follo the instructions belo :

•Install the machine according to the instructions in the paragraph “Installation”;

•Install the machine so that it is far from people ho must not use it, especially children;

•Do not become distracted hile using the machine;

•Do not use loose clothing or open sleeves;

•Do not let anyone come close to the machine hile in use;

•Do not remove, cover or change the plates that are on the machine and, if they are

damaged, contact qualified and authorised personnel;

•Do not remove the transparent protection and do not change or exclude the mechanical

and electrical protections;

•Only slice permitted products; do not try slicing any products that are not allo ed;

•The area around the machine, here the food is laid and the floor here the operator

orks must al ays be kept clean and dry;

•Do not use the machine as a support surface and do not place any object on it that does

not pertain to normal cutting operations;

•Do not use the slicing machine hen, after a normal use, the distance bet een the

cutting edge of the blade and the blade protection ring is over 6 mm. (see paragraph

7.2);

•Do not use the machine ith electrical connections of a “temporary” nature, ith

temporary or not insulated ires;

•Periodically check the state of the mains cable and the cable gland on the machine

body, hen necessary have it replaced ithout delay by qualified personnel;

•Immediately stop the machine in the case of a defect, anomalous function, suspected

breakage, incorrect movements, unusual noise;

•Before cleaning or carrying out any maintenance, disconnect the machine from the

electric mains supply;

•Use protective gloves for cleaning and maintenance;

•The goods to be cut must be placed on and removed from the sliding plate ith the

carriage in a retracted position and the thickness regulating knob in the “O” position;

Use and maintenance

5

•Only use the moving handle placed on the arm or the handle on the food press for

moving the food plate during slicing;

•The use of accessories for cutting is not allo ed unless supplied by the maker

specifically for the machine;

•For any exceptional maintenance (replacing grindstones, blade, etc.) please contact the

manufacturer or qualified and authorized personnel.

2.2 Guarantee and manufacturer’s responsibility

The guarantee of a good function and a complete conformity of the machines, that are to be

used accordingly, depends on the correct application of the instructions contained in this

manual.

The manufacturer declines all direct and indirect responsibility deriving from:

-Not follo ing the instructions in the manual;

-Untrained personnel using the machine;

-Using the machine so that it does not conform to specific regulations in force in the

country of installation;

-Unauthorized changes and/or repairs to the machine;

-The use of accessories and spare parts that are not original;

-Outstanding events.

If the machine is sold or given a ay, this automatically means that the manufacturer is no

longer responsible for the machine in question except for anything regarding the EEC

directive 85/374 (responsibility for any construction faults of the product).

2. The user’s obligations

The user must scrupulously observe the instructions in this manual for the manufacturer’s

guarantee to be valid and particularly:

- al ays respect the limits of the machine;

- al ays carry out a constant and diligent maintenance;

- make sure the persons using the machine are qualified and able.

2.4 Markings - Plates

The follo ing plate is installed on the machine:

- manufacturer’s identification plate, machine plate, technical data plate and EC marking;

placed on the base, left- hand side.

Use and maintenance

6

. TECHNICAL CHARACTERISTICS

.1 Data sheets

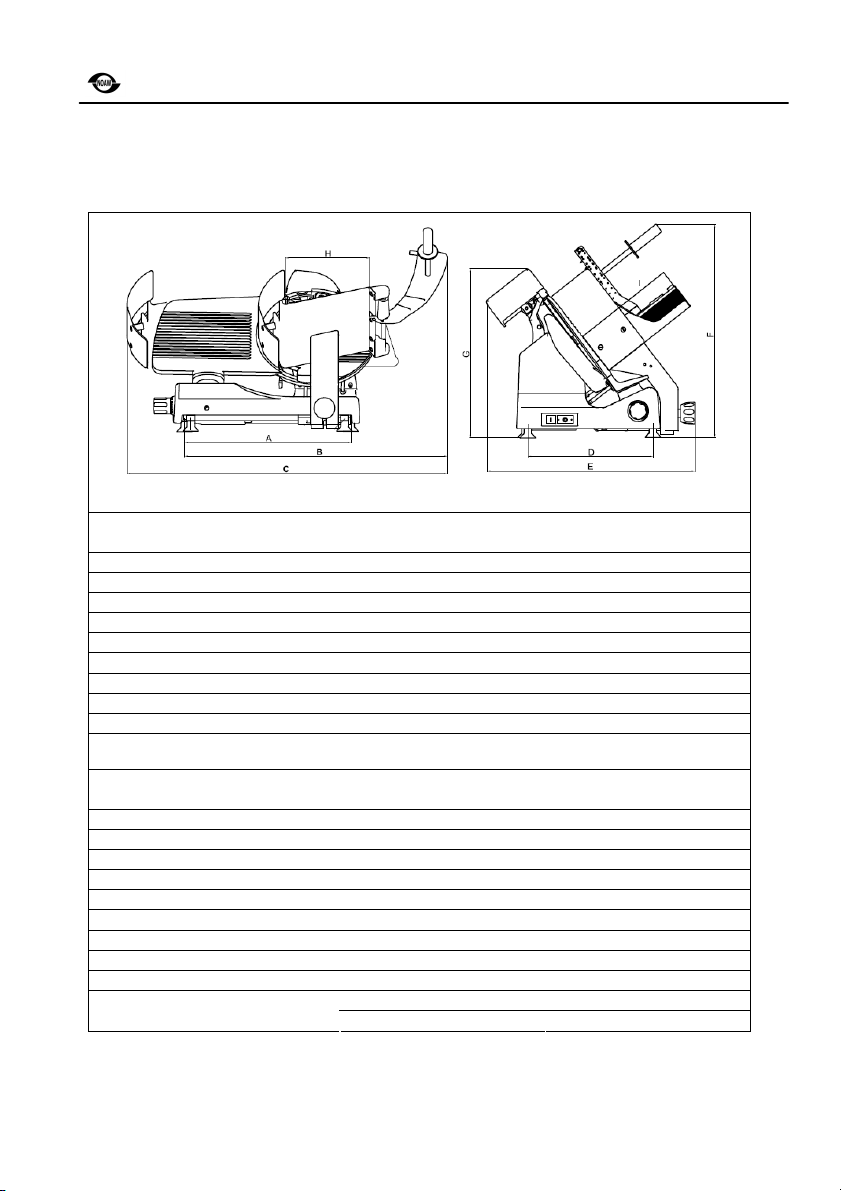

DIMENSIONS

Blade diameters 50 70

A 540 mm 540 mm

B 830 mm 830 mm

C 955 mm 955 mm

D 395 mm 395 mm

E 660 mm 660 mm

F 525 mm 525 mm

G 670 mm 670 mm

H 300 mm 300 mm

I 350 mm 350 mm

TECHNICAL DATA

Blade diameters 50 70

Blade turns/1’ 210 rpm 210 rpm

Carriage movement 365 mm 365 mm

Cut’s capacity Ø 260 mm 270 mm

Cut’s capacity 290 X 220h. mm 290 X 230h. mm

Thickness adjuster 0 ÷ 22 mm 0 ÷ 22 mm

Blade diameters 350 mm 370 mm

Base dimensions 600 x 450 mm 600 x 450 mm

Net eight 45 Kg 47 Kg

Motor po er 0.37 kW 0.37 kW

230V 50Hz single phase 230V 50Hz single phase Electrical characteristics

400V 50 Hz three-phase 400V 50 three-phase

Use and maintenance

7

.2 Furnished items and accessories

The follo ing documents and accessories are supplied ith the machine, unless other ise

requested;

- instruction manual for use and maintenance;

- EC conformity declaration;

- accessories: lubricating oil for carriage guide bars and food press.

. Products that can be sliced

The following are produtcs that can be sliced:

- all types of cold cuts (cooked, ra smoked);

- boneless meat (cooked or ra at a temperature of no lo er than +3°C);

- bread and cheeses (those that can be sliced, such as Gruyere, Fontina, etc.).

.4 Products that cannot be sliced

The following are products that cannot be sliced because they could cause damage to

people and equipment:

- frozen food;

- deep-frozen food;

- food ith bones (meat and fish);

- vegetables;

- any other product not meant for consumption.

IDENTIFICATION PLATES OF THE MANUFACTURER, MACHINE, TECHNICAL DATA

AND EC MARKING.

Use and maintenance

8

4. DESCRIPTION

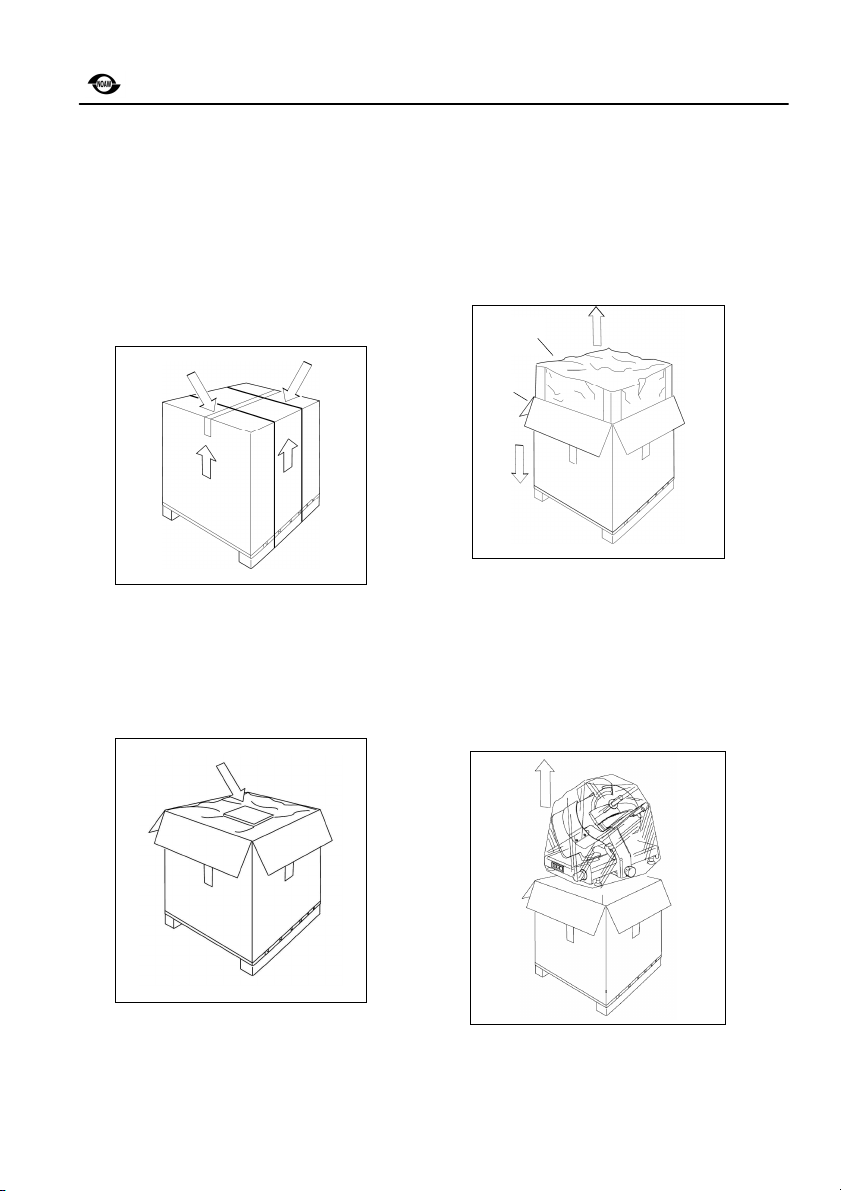

4.1 Unpacking

Check that the packaging is unopened and

undamaged; other ise immediately inform

the for arding agent or the area agent.

To take the machine out of the packaging

proceed as follo s:

1. Cut and remove the plastic straps;

2. Remove the staples from the top

of the box;

3. Open the box and take out the

copy of the instruction manual

hich is on top of the

polyurethane protection;

4. Continue as indicated in the

manual;

5. Push the upper cardboard box

do n (1) using the flaps so that

the next step is easier, that is,

removing the polyurethane

protection and the corner

reinforcements (2);

6. Remove the above mentioned

protection and the corner

reinforcements;

7. Lift and take out the machine

hich is rapped in a sheet of

transparent polyethylene;

ATTENTION: The machine must be lifted

by t o people, taking into account that it

eighs more on the side here the blade

is.

1

2

Use and maintenance

9

8. Once this operation is over, check the contents of the box and make sure it

corresponds to the label on the outside.

WARNING: The packaging components (plastic straps, cardboard, polyurethane foam) can

be thro n a ay ith normal solid astes and therefore there is no difficulty in disposing of

them.

Ho ever it is advisable to dispose of products separately (differential collecting) in conformity

ith theregulations in force for adequate recycling.

DO NOT DISCARD THE PACKAGING PRODUCTS IN THE ENVIRONMENT!

Use and maintenance

10

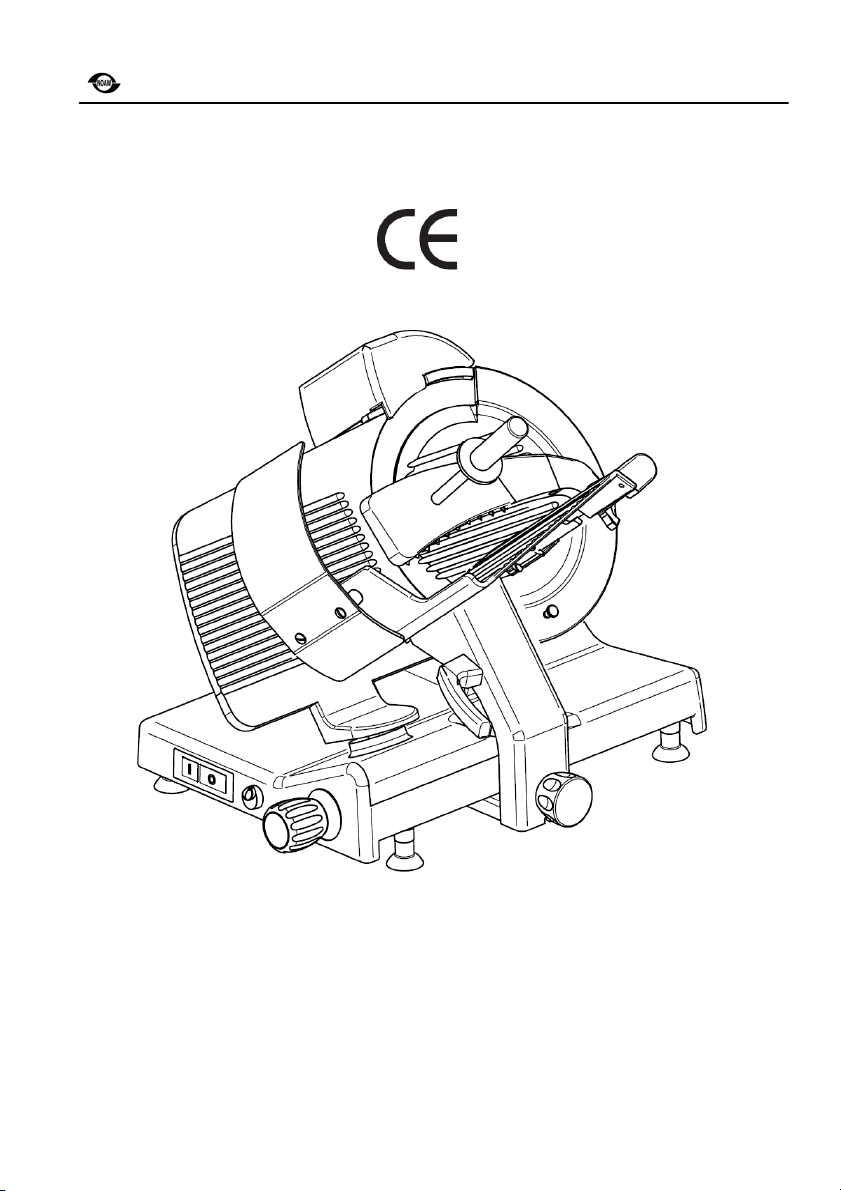

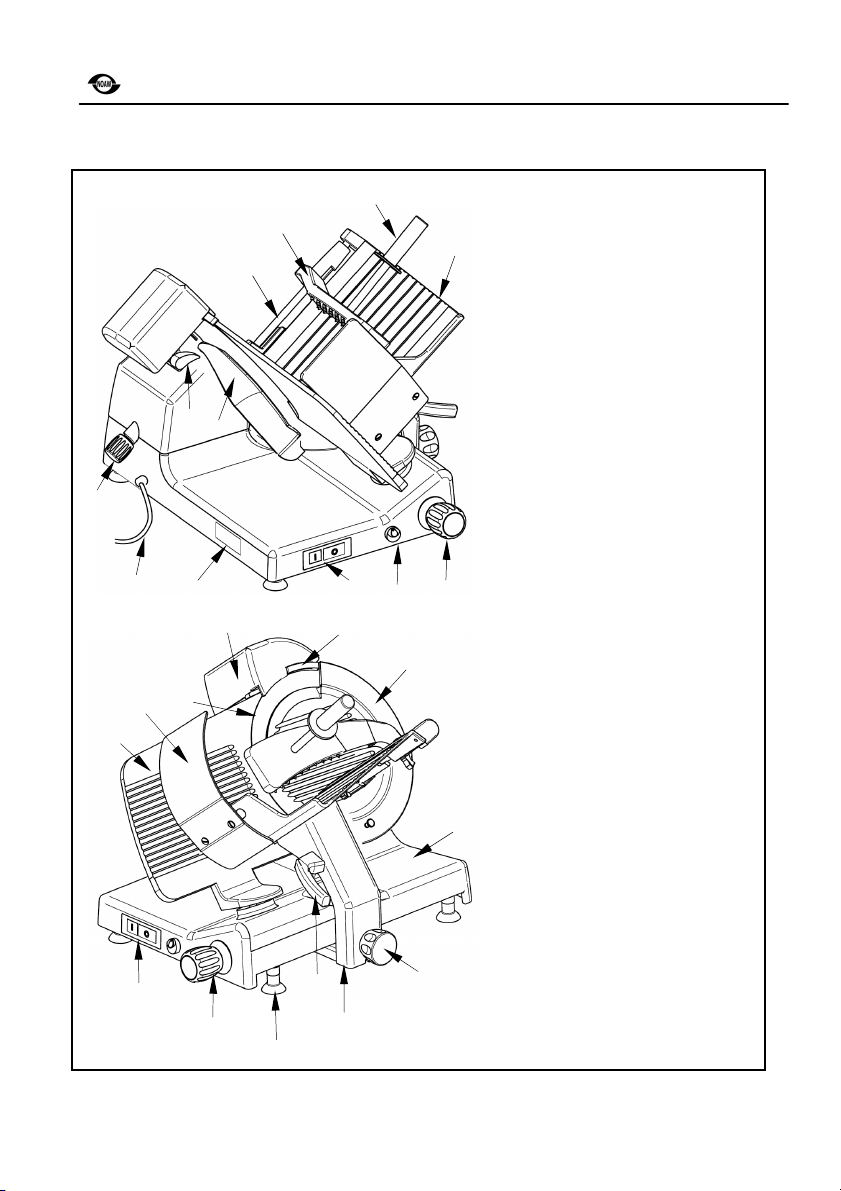

4.2 Main components

1. Feed cable

2. Identification plate, technical

data and EC marking

3. ON/OFF push button

4. Regulating knob for slice

thickness

5. Food table

6. Food press handle

7. Food press

8. Rod

9. Sharpener knob

10. Slice deflector

11. Foot

12. Knob for table pushing

13. Table support

14. Table locking handle

15. Base

16. Blade cover

17. Balde guard ring

18. Sharpener cover

19. Blade

20. Safety guard

21. Gauge plate

22. Tie rod

23. Lubricating point

1

2

3

4

5

6

7

8

9

3

4

10

11

12

14

15

16

17

18

19

20

2

1

13

23

22

Use and maintenance

11

4. General description

The slicing machine has been designed and made according to the EEC Directive 2006/42.

The machine offers the user:

-maximum safety hen in use, during cleaning and ordinary maintenance;

-maximum hygiene from the use of inoxidizable materials or adequately protected

against oxidization together ith an careful design of all the parts in food zone;

-maximum cutting precision and capacity together ith strength and reliability;

-the chance to ork continuously.

The machine is essentially made up of a base that holds a circular blade that is inclined,

operated by an electric motor, hich slices the food and a sliding carriage on bars, placed

under the above mentioned base, hich in turn supports the food plate, parallel to the cutting

edge of the blade.

The food table is made up of a plate and a sliding upper table, also has an appropriate self-

stopping device to keep the product in its proper place during cutting operations (food

press).

The thickness of the slice is regulated by a thickness plate behind the blade; this plate, on

hich the food is placed, can be moved transversally to the blade at the thickness of the

desired slice.

All the components of the machine are made of a light aluminium alloy and magnesium

Peraluman 3, polished and anodized, in stainless steel and plastic for food products as

according to the sanitary regulations in force so the structure is sturdy, reliable, easy to clean

and does not alter in time.

The cutting blade is operated by a self-ventilated motor, under the base; the motor

transmission is obtained ith gears, guaranteeing a quiet running. The transmission gear is

the top in terms of reliability, strong efforts, and it is able to cut the product even harder.

Starting and stopping is carried out by using the t o buttons at the front of the machine

hich are easily identifiable by their position; there is a light hich indicates the machine is

running. This command system prevents accidental starting of the machine after a possible

electric circuit interruption; this means the slicing machine can only be re-started intentionally.

The machine has a sharpener hich is extremely easy and safe to use.

The food plate, slice deflector and blade cover can be removed for cleaning.

4. .1 Safety

The mechanical safety devices are the follo ing:

•Irremovable safety ring around the blade (blade protection);

•Food plate hich can only be removed if the regulating knob of the thickness plate is in

the ‘zero’ position and the carriage is at the end of its position on the operator’s side.

Once the arm complete ith food plate has been removed the thickness plate is locked

in the above mentioned position;

•A set of aluminium and transparent protections on the food plate.

The electric safety devices are the follo ing:

•Start-up ith start and stop buttons ith a lo tension control circuit that also requires a

voluntary re-start of the machine in the case of an electric circuit interruption.

4. .2 Residual risks

WARNING: The safety ring around the blade is made according to the European regulation

(EN 1974:1998+A1) but this protection doesn’t completely eliminate risks in sharpening area.

When cleaning and sharpening the blade, be very careful and always concentrate on the

job at hand. We recommend the use of protective gloves.

Use and maintenance

12

5. INSTALLATION

5.1. Installing the machine

Install the machine on a surface hich is level,

smooth, dry and suitable for the eight of the

machine plus the food to be sliced; refer to

paragraph3.1.

WARNING: Check that there is nothing that

can get in the ay of the plate and the food

that is to be cut on the plate.

5.2. Command description

5.2.1 Start and stop buttons

- Press the button I (1) to start the blade;

- Press the button 0 (2) to stop the blade

moving.

5.2.2 Regulating knob for slice thickness

The thickness of the slice is regulated by

turning the graduated scale knob (3)

counterclock ise.

Regulating field: see paragraph 3.1.

5. Electrical connection

The machine must be installed close to an EEC

regulation socket in a system hich conforms

to the regulations in force ith:

- magnetothermal protection;

- automatic differential s itch;

- grounding system.

Before connecting, verify that the electric

supply mains is suitable for the machine by

checking the technical data plate on the

machine.

Max height

0.9 mt.

1

2

3

Use and maintenance

13

The slicer is fitted ith a po er supply cord of

about 2 metres length, complete ith a plug to

allo a simple disconnection from the electric

mains supply.

ALWAYS indicate the presence of the po er

supply cord if the slicer cannot be installed

near a socket and if in the installation zone

there is a transit of people.

If the po er supply cord is not long enough

you ill require the technical assistance service

and do not proceed ith a temporary electrical

connection.

5.4 Checking direction of blade rotation

(only for machine with three phase motors)

1. Start the machine;

2. Check the orking light is on;

3. Check the blade rotates in the direction

indicated by the arro (counterclock ise

looking at the machine from the side of the

blade cover);

4. If the blade goes round in the opposite

direction (clock ise) stop the machine

immediately and call a qualified person to

invert the feed wires of the plug.

5. Check the food plate and food press move

smoothly.

6. Check the orking and regulation of the

thickness plate.

6. USING THE SLICING MACHINE

6.1 Loading the goods on the plate and

cutting

1. Check that the regulating knob for slice

thickness is on ‘0’;

2. Pull back the carriage completely (to ards

the operator) to the loading position.

Use and maintenance

14

3. Lift up the food press and put it in the rest

position;

4. Place the food to be sliced on the plate

against the operator’s side. The food ill press

against the thickness plate because of its

eight.

Block it ith the food press by pressing do n

slightly;

5. Regulate the thickness of the slice.

Start the blade by pressing the start button I.

Grip the handle attached to the plate holder

arm and begin an alternate cutting movement;

6. When the eight or size of the goods do not

allo a proper cutting for reasons of eight,

use the food press hand-grip;

7. At the end of the cutting operations turn the

thickness regulating knob back to ‘0’ and pull

back the carriage.

Stop the blade movement by pushing the stop

button 0.

Use and maintenance

15

6.2 Cleaning the slicing machine

6.2.1 General information

The machines must be properly cleaned at

least once a day; if necessary even more.

If the machines have not been used for a hile

they must be cleaned before use as ell.

6.2.2 Disassembling machine for cleaning

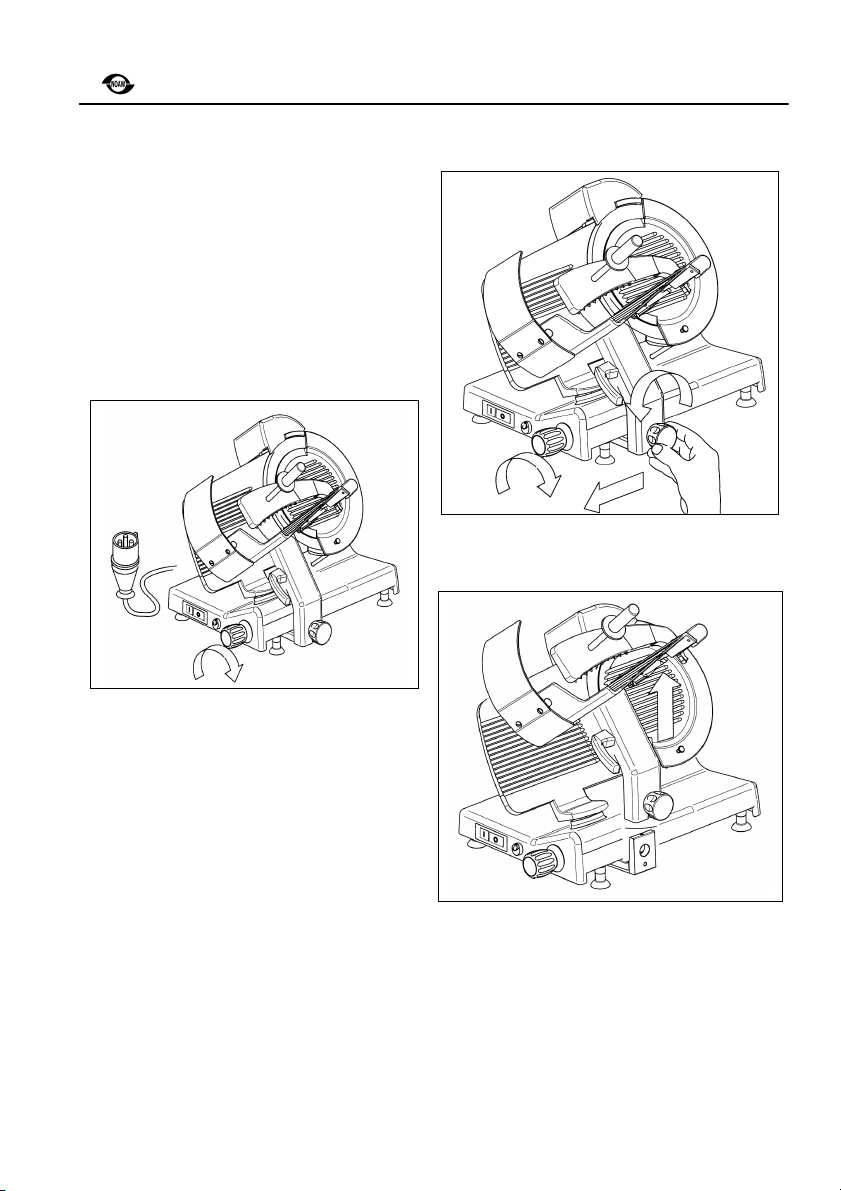

1. Disconnect the plug from the electric mains

supply;

2. Turn the regulating knob of the thickness

plate to ‘0’;

3. Remove the various components as

described in the follo ing paragraphs.

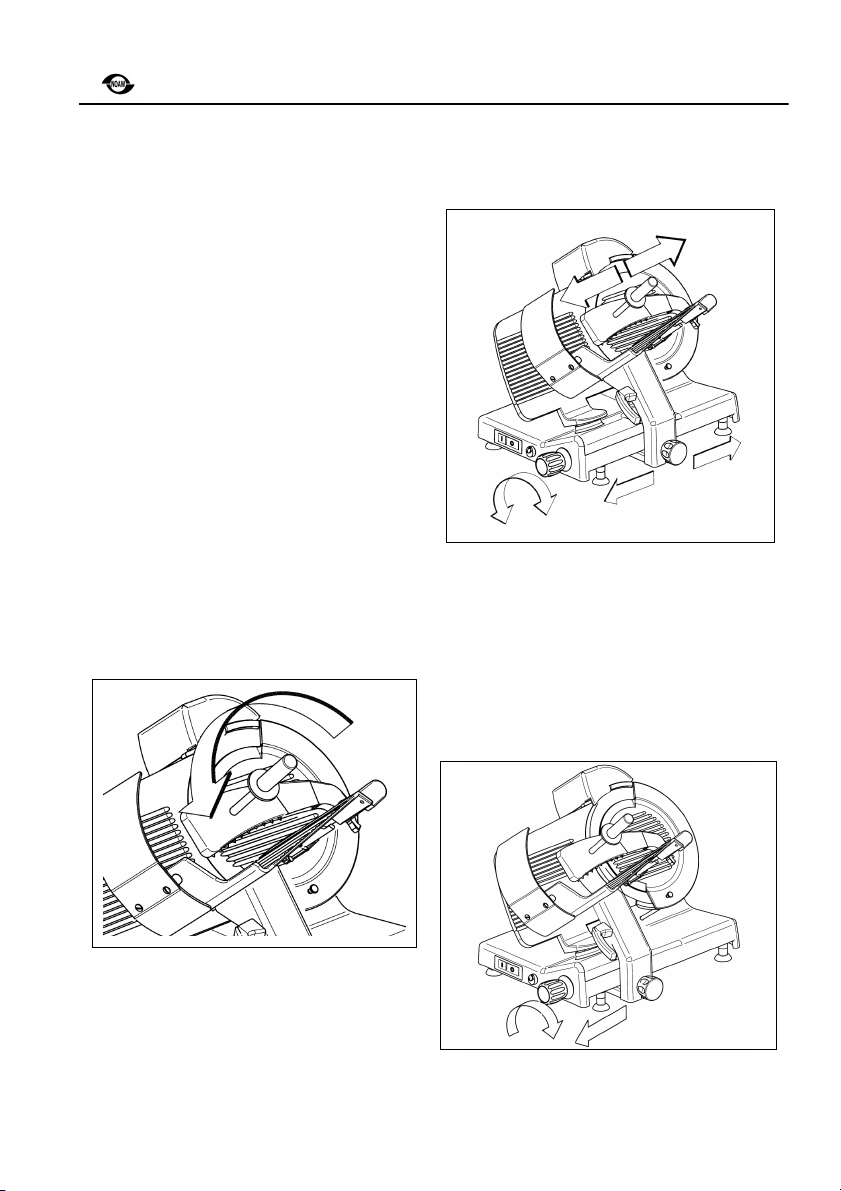

Disassembling the food table

1. With the regulating knob of the thickness

plate on ‘0’ pull back the plate holder support

all the ay to ards the operator;

2. Turn the locking knob counterclock ise all

the ay hile keeping the support at the end

until the safety device of the thickness plate

can be heard.

WARNING: To correctly carry out this

operation it could be necessary to move the

thickness regulating knob at the same time

taking it 1-2 mm over the ‘0’ position.

3. Take out the hole group by pulling it

up ards.

Use and maintenance

16

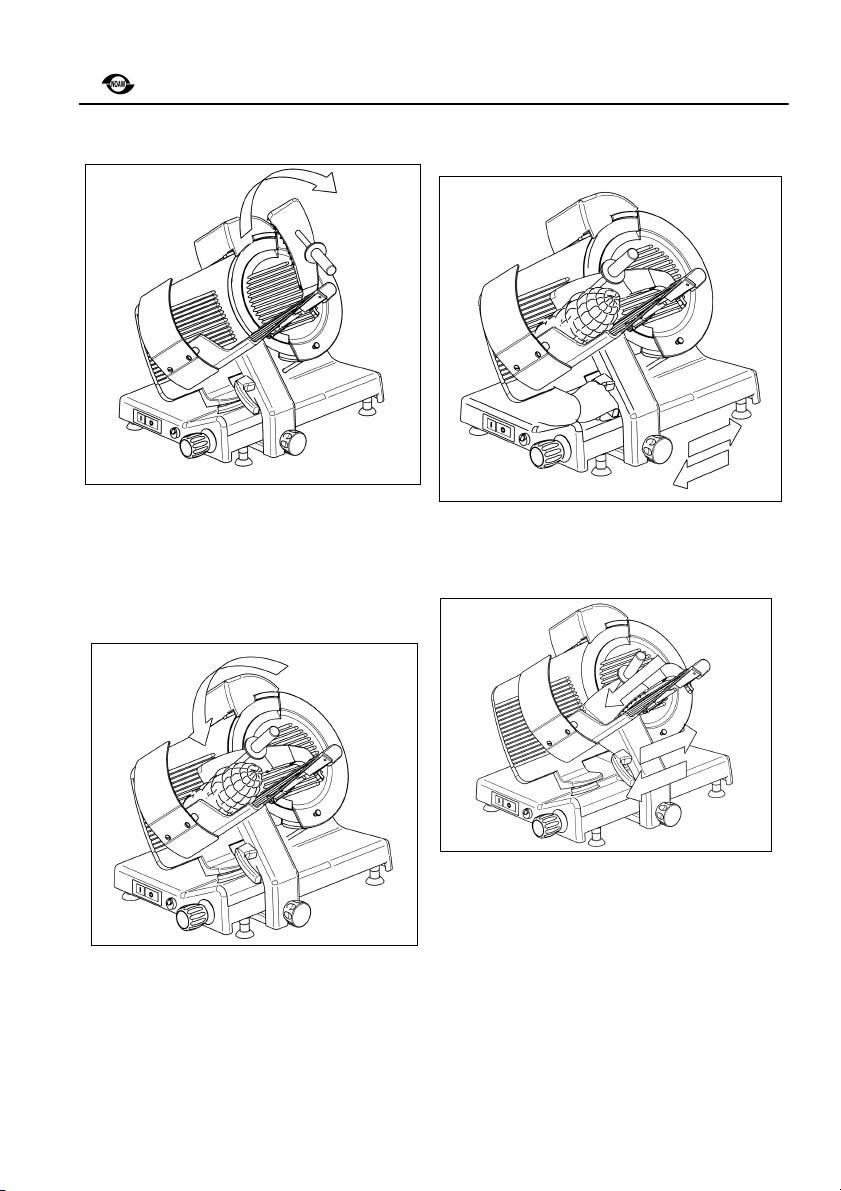

Disassembling the blade cover

1. Completely unscre (counterclock ise) the

tension rod knob of the blade cover block;

2. If the blade cover is tight, loosen it ith

pressure on the tension rod knob.

Take out the tension rod and remove the blade

cover using the special knob.

Disassembling the slice deflector

1. Rotate and lift the slice deflector as in the

figure, it’s not necessary to remove it, but it is

possible to extract it pulling the slice deflector

to yourself;

6.2. Cleaning the machine and the parts

that have been removed

PRODUCT TO BE USED

Only use hot ater and a biodegradable

detergent for dishes ith a 7-8 PH, at a

temperature of no lo er than 30°C using a soft,

spongy cloth and a semi-rigid nylon brush for

the plate and the sharp food press.

WARNING: For cleaning the sharp areas of the

plates, the food press and the blade, e

recommend using protective gloves.

Rinse ell ith a lot of hot clean ater and dry

ith a soft cloth or a spongy material.

Do not clean the slicer ith ater or stream jets

or similar methods.

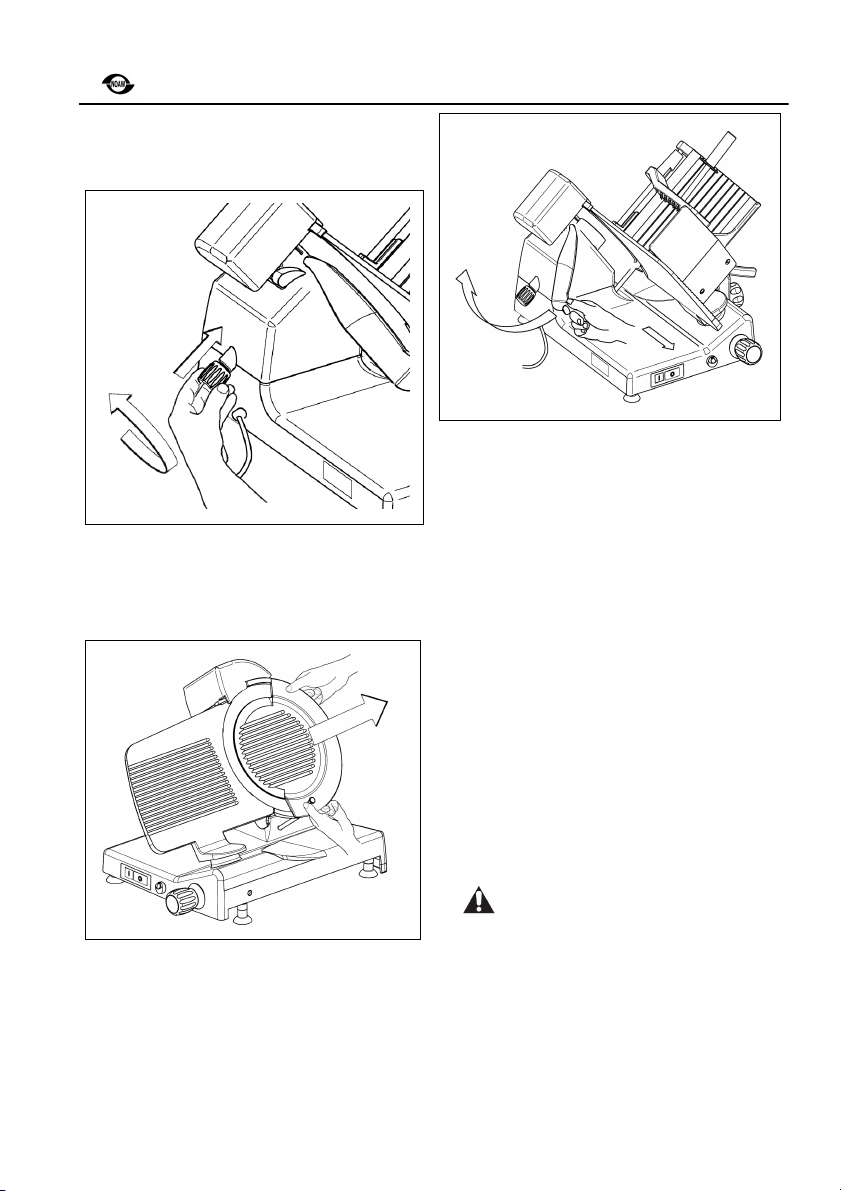

Cleaning the blade

WARNING: Use protective gloves

and concentrate on the job at

hand.

DANGER!

1. Press a damp cloth on the surface of the

blade and move it slo ly from the centre to the

edge, as sho n in the picture, on the side of

the blade cover and on the other side;

2. Dry in the same ay using a dry cloth.

Use and maintenance

17

Cleaning the safety ring

1. Pass a damp cloth bet een the blade and

the safety ring as sho n in the picture;

Cleaning the machine body

Clean the machine body ith a damp cloth or a

sponge rinsing frequently ith hot ater.

Dry carefully.

Cleaning the components in the base

The components contained in the base do not

need any special cleaning; occasionally

remove the dust that can accumulate in the

end area of the carriage and of the thickness

plate regulation.

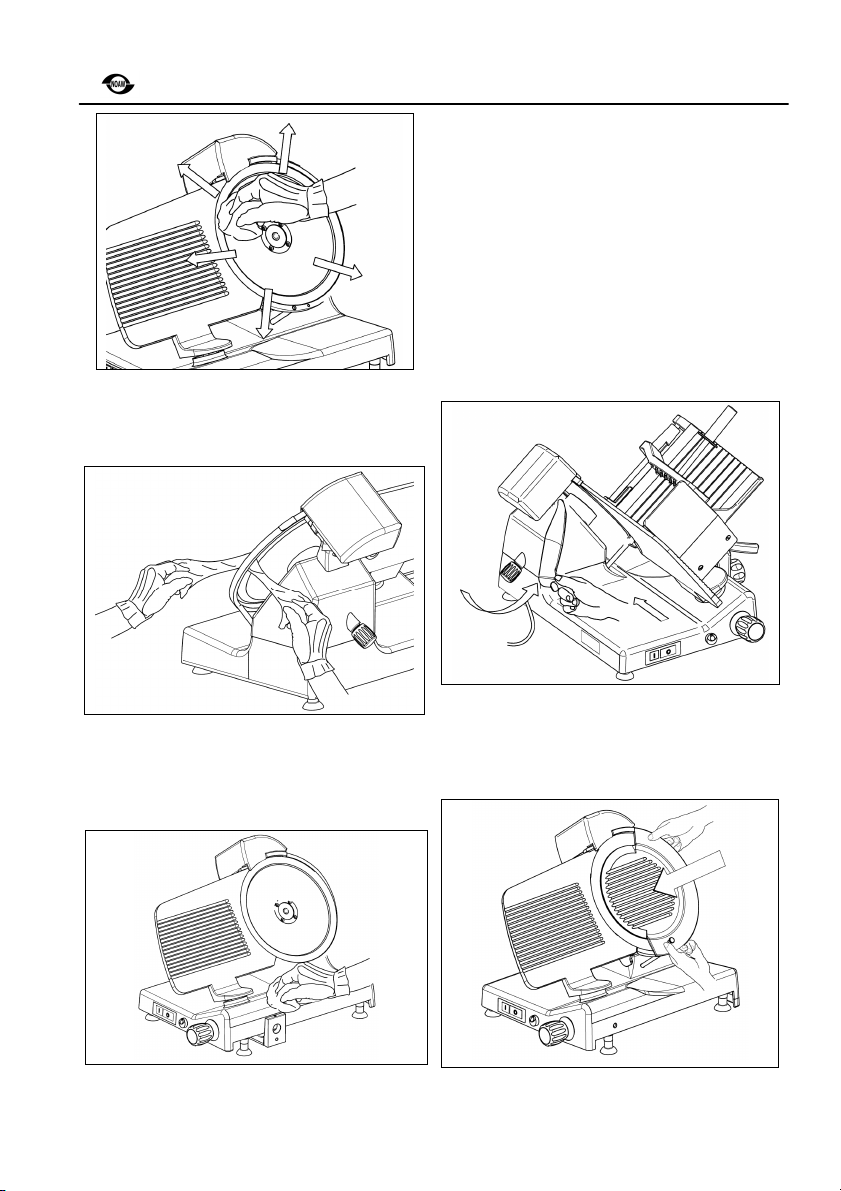

6.2.4 Reassembling the slicing machine

Reassembling the slice de

1. Insert the pin of the slice deflector in the

centre and rotate carefully bringing the slice

deflector in the original position, as sho n in

the figure.

Reassembling the blade cover

1. Replace the blade cover as sho n in the

picture making sure the square section joint is

in its proper place;

Use and maintenance

18

2. Insert the tie rod for locking and scre

completely.

Reassembling the food table

1. Insert the entire group on the carriage as

sho n in the picture;;

2. Tighten the locking knob;

3. Check that the carriage moves freely;

4. Check that the slice thickness regulator

orks correctly.

Use and maintenance

19

7. MAINTENANCE AND REPAIRS

7.1 General information

The operator is allo ed to carry out the follo ing maintenance:

- Blade sharpening, periodically;

The interval and length of the sharpening obviously depend on the use of the machine ( ork

times and type of product used)

- Lubrication of the carriage guide bars, eekly;

- Lubrication of guide rod/s of the plate and the food press, eekly;

- Check the conditions of the electric cable and the cable gland on the base of the machine,

periodically.

Maintenance to be carried out exclusively by personnel authorized by the manufacturer is as

follo s:

- Replacing the blade;

- Replacing the sharpener grindstones;

- Replacing the components of the electric system under the base;

- Repairing the structural parts, repairing and/or replacing components under the base.

7.2 Sharpening the blade

NOTE: The sharpening operation is to be carried out only hen the machine has been carefully

cleaned as described in the previous paragraphs..

WARNING: The blade can be sharpened up until the distance between the cutting edge of

the blade and the inside border of the protection is no more than 6 mm., corresponding to a

decrease of about 10 mm. of the size of the original diameter. Once this value has been

reached, it is NECESSARY TO REPLACE THE BLADE and this operation must be carried

out EXCLUSIVELY by personnel authorized to by the manufacturer.

6mm

This manual suits for next models

1

Table of contents

Other Noaw Kitchen Appliance manuals

Noaw

Noaw NS300M Troubleshooting guide

Noaw

Noaw 330/83 Troubleshooting guide

Noaw

Noaw 30E Specification sheet

Noaw

Noaw NS220 Specification sheet

Noaw

Noaw NS220 User manual

Noaw

Noaw 300/10H Troubleshooting guide

Noaw

Noaw TWS Service manual

Noaw

Noaw A300 Specification sheet

Noaw

Noaw NS350HDA Specification sheet

Noaw

Noaw A370G/L Specification sheet