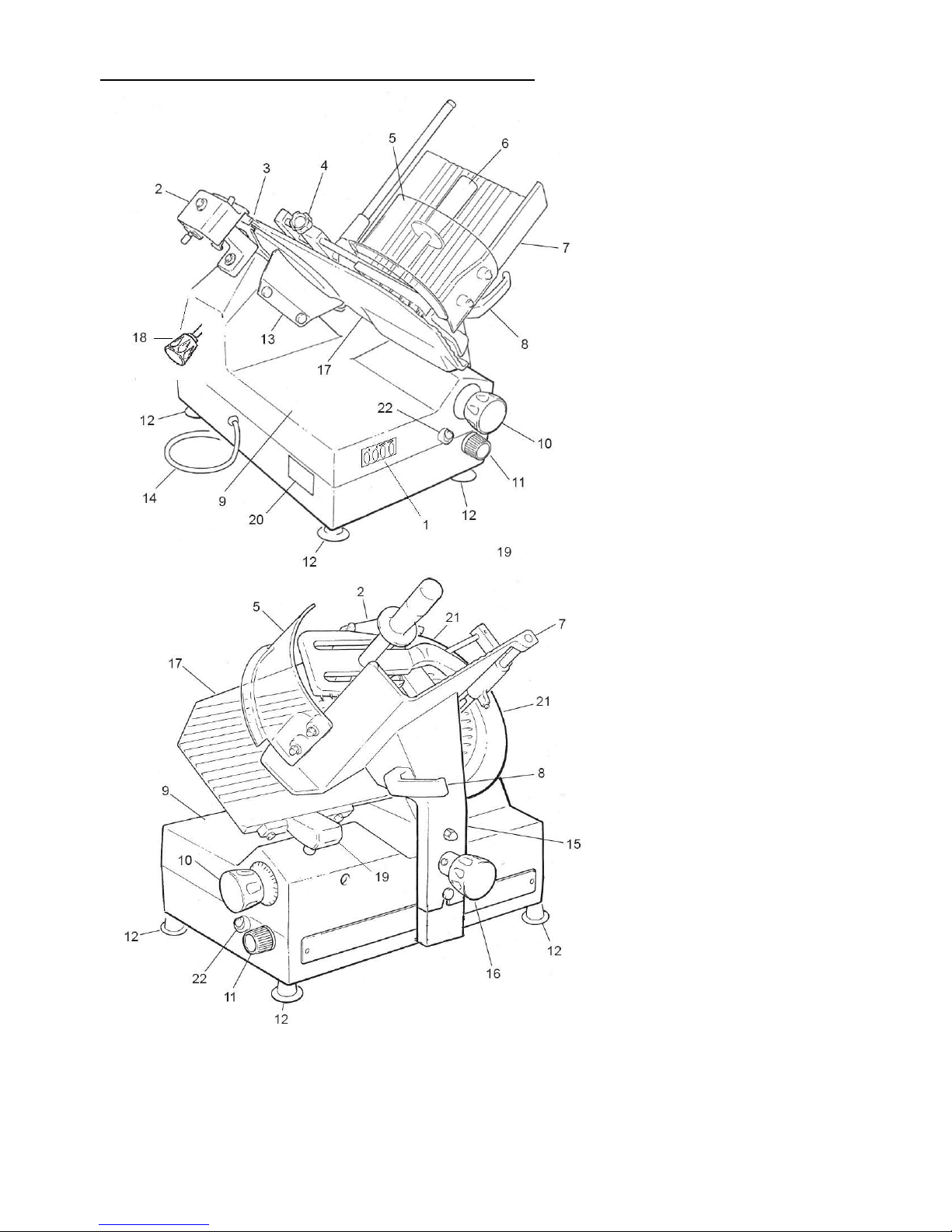

GENERAL INFORMATION

MACHINE LIMITS, SAFETY REGULATIONS

The machine has been designed and produced in accordance with EEC directives 98/37

EEC, 2006/95 EEC, 89/336 EEC and the European norm EN 1974 (Slicing machines –

Hygiene and safety specifications.

LIMITS OF THE MACHINE

The machines have been designed and made for slicing food, of the type and size as

specified in paragraph “Technical features and products that can be sliced”. This manual

reports the technical and constructive features of the machines as well as installation

instructions, use and maintenance.

ENVIRONMENTAL CONDITIONS OF USE

The slicers cannot be used in opened places and/or exposed to the atmospheric agents:

they must be placed in a secure environment which has safe conditions as established

by the norms in force so that personnel can operate in the best possible conditions.

The machines must not be used where there are spray of water, vapour or smoke or

corrosive and/or abrasive powders, in the presence of flames and/or heat with

temperatures above those permitted and with the risk of fire or explosions and where the

use of explosion-proof and spark-proof components are prescribed.

- Operation temperature from -5°C to +40°C

- Max relative humidity 95%

GENERAL SAFETY REGULATIONS

The slicing machine must be used only by an adequately trained person who has carefully

read the contents of this manual.

The operators must be over 18 years of age, in perfect mental-physical conditions, have

the right attitude and capacity and necessary knowledge to utilize and keep the normal

maintenance of simple mechanical and electrical components.

For a better use of the machine follow the instructions below:

Install the machine according to the instructions in the paragraph “Installation”;

Install the machine so that it is far from people who must not use it, especially

children;

Do not become distracted while using the machine;

Do not let personnel who have not carefully read and understood the contents of this

manual using the machine;

Do not use loose clothing or open sleeves;

Do not let anyone come close during cutting operations;

Do not remove the transparent protection and do not change or exclude the

mechanical and electrical protections;

Slice only permitted products; do not try slicing any products that are not allowed;

The area around the machine, where the food is laid and the floor where the

operator works, must always be kept clean and dry;

Do not use the machine as a support surface and do not place any object on it that

does not pertain to normal cutting operations;

Do not use the slicing machine when, after a normal use, the distance between the

cutting edge of the blade and the blade protection ring is over 6 mm, call a qualified

and authorized person to replace the blade;

Do not use the machine with electrical connections of a “temporary” nature, with

temporary or not insulated wires, do not use extension cords;

Periodically check the state of the mains cable and the cable gland on the machine

body, when necessary have it replaced without delay by qualified personnel;