Noblelift PTE12N manual

Version 07/2019

PTE12N-SMS-001-EN

xyz

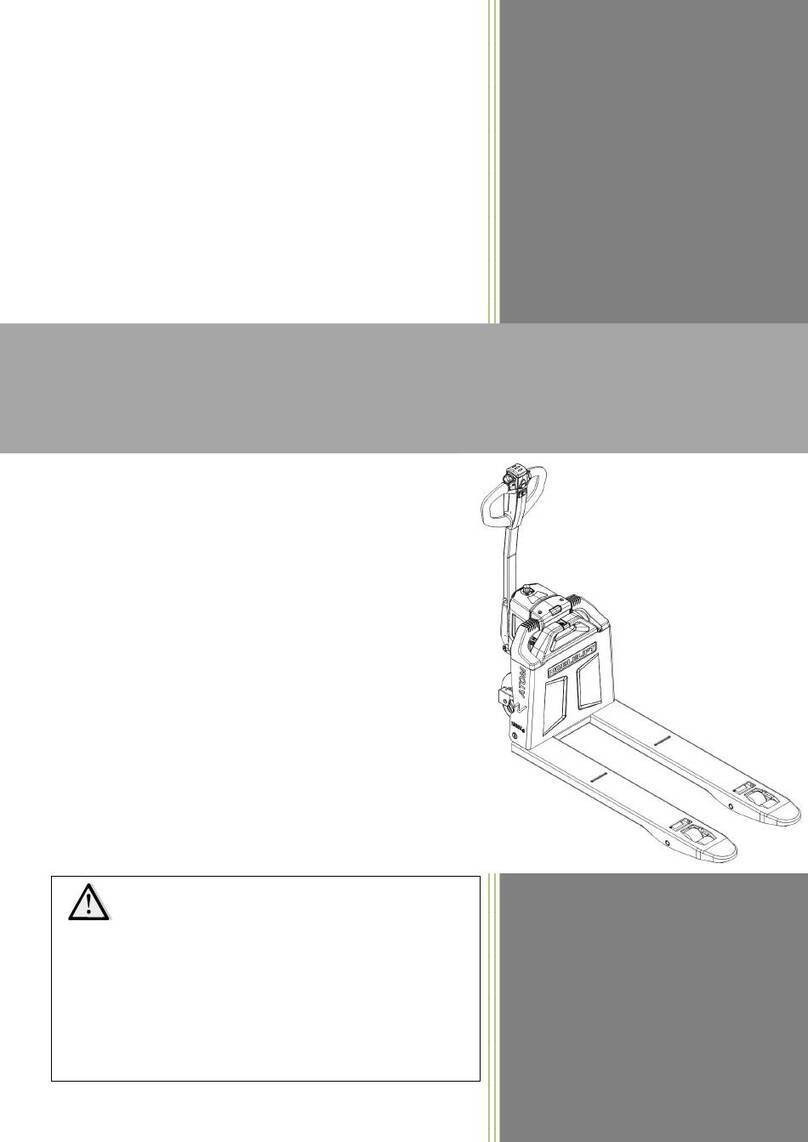

INSTRUCTION HANDBOOK

Electric Pallet Truck

PTE12N

WARNING

Do not use the pallet truck before reading and

understanding these operating instructions.

NOTE:

•Please check the designation of your

present type at the last page of this

document as well as on the ID-plate.

•Keep for future reference.

1

FOREWORD

Before operating the truck, read this ORIGINAL INSTRUCTION HANDBOOK carefully and understand

the usage of the truck completely. Improper operation could create danger.

This handbook describes the usage of different electric pallet trucks. When operating and servicing the

truck, make sure, that it applies to your type.

Keep this handbook for future reference. If this or the warning/ caution labels are damaged or got lost,

please contact your local dealer for replacement.

This truck complies with the requirements according to EN 3691-1; -5 (Industrial trucks- safety

requirements and verification, part 1; part 5), EN 12895 (Industrial trucks- electromagnetic compatibility),

EN 12053 (Safety of industrial trucks- test methods for measuring noise emissions), EN 1175-1

(Industrial truck safety –electrical requirements), assumed the truck is used according to the described

purpose.

The noise level for this machine is 69 dB(A) according to EN 12053.

ATTENTION:

•Environmentally hazardous waste, such as batteries, oil and electronics, will have a

negative effect on the environment, or health, if handled incorrectly.

•The waste packages should be sorted and put into solid dustbins according to the

materials and be collected disposal by local special environment protection bureau. To

avoid pollution, it’s forbidden to throw away the wastes randomly.

•To avoid leaking during the use of the products, the user should prepare some

absorbable materials (scraps of wooden or dry duster cloth) to absorb the leaking oil in

time. To avoid second pollution to the environment, the used absorbable materials

should be handed in to special departments in terms of local authorities.

•Our products are subject to ongoing developments. Because this handbook is only for

the purpose of operating /servicing the pallet truck, therefore please have

understanding, that there is no guarantee out of particular features out of this handbook.

NOTE: On this manual, the left sign means warning and danger, which can lead to

death or serious injury if not followed.

Copyright

The copyright remains with the company, mentioned on the CE- certificate at the end of this document or,

if sold within the USA, with the company, mentioned on the company sticker.

2

TABLE OF CONTENTS

1. CORRECTAPPLICATION ................................................................................................................. 4

2. DESCRIPTION OF THE PALLET TRUCK......................................................................................... 5

a. Overview of the main components................................................................................................. 5

b. Main technical data......................................................................................................................... 6

c. Description of the safety devices and warning labels (Europe and other, excepting USA)........... 8

d. Identification plate........................................................................................................................... 9

3. WARNINGS, RESIDUAL RISK AND SAFETY INSTRUCTIONS ...................................................... 9

4. COMMISSIONING, TRANSPORTING, DECOMMISSIONING ....................................................... 10

a. Commissioning ............................................................................................................................. 10

b. Lifting/ transportation .................................................................................................................... 10

c. Decommissioning...........................................................................................................................11

5. DAILY INSPECTION..........................................................................................................................11

6. OPERATING INSTRUCTIONS ........................................................................................................ 12

a. Parking.......................................................................................................................................... 12

b. Lifting............................................................................................................................................. 13

c. Lowering........................................................................................................................................ 13

d. Travelling....................................................................................................................................... 13

e. Steering......................................................................................................................................... 14

f. Braking.......................................................................................................................................... 14

g. Malfunctions.................................................................................................................................. 14

h. Emergency.................................................................................................................................... 14

7. BATTERY CHARGINGAND REPLACEMENT................................................................................ 15

a. Replacement.................................................................................................................................15

b. Battery indicator............................................................................................................................ 16

c. Charging........................................................................................................................................ 16

8. REGULAR MAINTENANCE............................................................................................................. 17

a. Maintenance checklist................................................................................................................... 18

b. Lubricating points.......................................................................................................................... 20

c. Check and refill hydraulic oil......................................................................................................... 20

d. Checking electrical fuses.............................................................................................................. 21

9. TROUBLE SHOOTING .................................................................................................................... 22

10. WIRING/ CIRCUIT DIAGRAM.......................................................................................................... 23

a. Electrical circuit diagram............................................................................................................... 23

b. Hydraulic circuit............................................................................................................................. 27

11. SPECIALIZED STIPULATIONS FOR THE US- AMERICAN MARKET........................................... 28

a. Foreword/ Compliance.................................................................................................................. 28

b. Description warning labels (only US- market).............................................................................. 29

c. Technical data for US market........................................................................................................ 31

12. DECLARATION OF CONFORMITY (valid, if sold within the EU).................................................... 33

3

4

1. CORRECT APPLICATION

It is only allowed to use this electric pallet truck according to this instruction handbook.

The trucks described in this handbook are self propelled electric power pallet trucks. The trucks are

designed to lift, lower and transport palletized loads.

A wrong usage can cause human injuries or can damage equipment.

The operator/ the operating company has to ensure the correct usage and has to ensure, that this pallet

truck is used only by staff, which is trained and authorized to use this truck.

The pallet truck has to be used on substantially firm, smooth, prepared, level and adequate surfaces.

The truck is intended to be used for indoor applications with ambient temperatures between +5C and +

40C and for various transportation applications without crossing permanent obstacles or potholes. The

work on ramps is allowed if ramp is not exceeding the allowed angle. While operating, the load must be

placed approximately on the longitudinal centre plane of the truck.

Lifting or transporting people is forbidden.

If used on tail lifts or loading ramps, please ensure that these are used correctly according to the

operating instructions.

The capacity is marked on capacity sticker as well on the Identification plate. The operator has to

consider the warnings and safety instructions.

Operating lighting must be minimum 50 Lux.

Modification

No modifications or alterations to this pallet truck which may affect, for example, capacity, stability or

safety requirements of the truck, shall be made without the prior written approval of the original truck

manufacturer, its authorized representative, or a successor thereof. This includes changes affecting, for

example braking, steering, visibility and the addition of removable attachments. When the manufacturer

or its successor approve a modification or alteration, they shall also make and approve appropriate

changes to capacity plate, decals, tags and operation and maintenance handbooks.

Only in the event that the truck manufacturer is no longer in business and there is no successor in the interest to the business, may the

user arrange for a modification or alteration to a powered industrial truck, provided, however, that the user:

a) arranges for the modification or alteration to be designed, tested and implemented by an engineer(s) expert in industrial trucks and

their safety,

b) maintains a permanent record of the design, test(s) and implementation of the modification or alteration,

c) approves and makes appropriate changes to the capacity plate(s), decals, tags and instruction handbook, and

d) affixes a permanent and readily visible label to the truck stating the manner in which the truck has been modified or altered, together

with the date of the modification or alteration and the name and address of the organization that accomplished those tasks.

By not observing these instructions, the warranty becomes void.

5

2. DESCRIPTION OF THE PALLET TRUCK

a.Overview of the main components

1. Safety (belly) button

2. Tiller

3. Discharge indicator and charging indicating LED

4.Key switch

5. Emergency button

6. Hydraulic unit cover

7. Chassis

8. Fork

9. Load roller

10. Battery

11. Apron

12. Driving unit

13. Side roller (option)

Fig. 1: Overview main components

6

b.Main technical data

Table 1: Main technical data for standard version

Type sheet for industrial truck acc. to VDI 2198

Distinguishi

ng mark

1.2

Manufacturer`s type designation

PT E12N

1.3

Drive

Battery

1.4

Operator type

Pedestrian

1.5

Load Capacity / rated load

Q (t)

1.2

Fig. 2: Technical data

7

1.6

Load centre distance

c (mm)

600

1.8

Load distance ,centre of drive axle to fork

x (mm)

942

1.9

Wheelbase

y (mm)

1185

Weight

2.1

Service weight

kg

124

129

2.2

Axle loading, laden front/rear

kg

355 / 972

425 / 908

2.3

Axle loading, unladen front/rear

kg

101 / 27

106 / 27

Tyres, chassis

3.1

Tires

Polyurethane (PU)

3.2

Tire size,front

x w (mm)

210×70

3.3

Tire size,rear

x w (mm)

80×93(80×70)

3.4

Additional wheels(dimensions)

x w (mm)

-/80×30

3.5

Wheels,number front/rear(x=driven

wheels)

1x/ 2(1x/ 4) or 1x +2/ 2(1x +2/ 4)

3.6

Tread, front

b10 (mm)

-/420

3.7

Tread, rear

b11 (mm)

380

525

Dimensions

4.4

Lift

h3 (mm)

115

4.9

Height of tiller in drive position min./ max.

h14 (mm)

700 / 1160

4.15

Height, lowered

h13 (mm)

80

4.19

Overall length

l1 (mm)

1537

4.20

Length to face of forks

l2 (mm)

387

4.21

Overall width

b1 (mm)

540

685

4.22

Fork dimensions

s/e/l (mm)

48 / 160 / 1150

4.25

Width across forks

b5 (mm)

540

685

4.32

Ground clearance, centre of wheelbase

m2 (mm)

32

4.34

Aisle width for pallets800X1200

lengthways (200mm safe distance)

Ast (mm)

2007

4.35

Turning radius

Wa (mm)

1337

Performance

data

5.1

Travel speed, laden/ unladen

km/h

4.6 / 4.8

5.2

Lift speed, laden/ unladen

m/s

0.031 / 0.037

5.3

Lowering speed, laden/ unladen

m/s

0.069 / 0.051

5.8

Max. gradeability, laden/ unladen

%

4 / 16

5.10

Service brake

Electromagnetic

Electric- engine

6.1

Drive motor rating S2 60min

kW

0.65

6.2

Lift motor rating at S3 10%

kW

0.50

6.3

Battery acc. to DIN 43531/ 35/ 36 A, B, C,

no

No

6.4

Battery voltage, nominal capacity K5

V / Ah

24 /15

6.5

Battery weight

kg

4.4

6.6

Energy consumption acc. to VDI cycle

kWh/h

0.14

Addition

data

8.1

Type of drive control

DC speed Control

8.4

Sound level at driver`s ear acc. to EN

12053

dB(A)

<70

8

c.Description of the safety devices and warning labels (Europe

and other, excepting USA)

For the USA –market, the description of the safety and warning labels is mentioned in

chapter 11.

A Sticker to read and follow this instruction

B Emergency button sticker

C Sign oil filling point

D Warning sticker

E “No passengers” decal

F Crane hook label

G Identification plate (ID-plate)

H Capacity sticker

I Battery ID plate

J No collision sticker

K Battery warning sticker

L Charger ID plate

R Sticker to read and follow service manual

T Warning sticker

The truck is equipped with an emergency switch (5) which stops all lifting-, lowering-, driving- functions

and engages the failsafe electromagnetic brake when it is pressed. By turn this button clockwise, the

truck can be operated after the controller checked the functions. Before operating, insert the key. To

prevent against unauthorized access, press emergency switch (5) or remove key (4).

The truck is equipped with a safety (belly) button (1) which switches the driving function away from the

operator, if the truck travels towards the operator and the tiller is activated in the tillers operating zone.

Follow also the instructions given on the decals. Replace the decals if they are damaged or missing.

Fig. 3: Safety and warning labels

9

d.Identification plate

1 Designation, type

2 Serial number

3 Rated capacity in kg

4 Supply voltage in V

5 Own mass (self weight) in kg without battery

6 Name and address of manufacturer)

7 Battery weight minimum/ maximum

8 Nominal power in kW

9 Load center distance

10 Manufacturing date

11 Option

3. WARNINGS, RESIDUAL RISK AND SAFETY INSTRUCTIONS

DO NOT

•Put foot or hand under or into the lifting mechanism.

•Allow other person than the operator to stand in front of or behind the truck when it is

moving or lifting/lowering.

•Overload the truck.

•Put foot in front of the wheels, injury could result.

•Lift people. People could fall down and suffer severe injury.

•Push or pull loads

•Side or end load. Load must be distributed evenly on the forks.

•Use the truck with unstable, unbalanced not stable load.

•Use truck without manufacturer’s written consent.

•Lifted loads could become unstable at wind forces. In the case of wind forces do not

lift the load if there is any influence to the stability

Fig. 4: Identification plate

1

2

4

5

3

7

If sold to the EU, here the

place of the CE marking

6

8

9

10

11

10

Watch difference in floor levels when driving. Load could fall down or the truck could get uncontrollable.

Keep watching the condition of load. Stop operating the truck if load becomes unstable.

Brake the truck and activate the emergency button (5) by pushing when sliding load on or off the truck. If

the truck has any malfunctions, follow chapter 9.

Practice maintenance work according to regular inspection. This truck is not designed to be water

resistant. Use the truck under dry condition. Prolonged continuous operation might cause damage of the

power pack. Stop operation if temperature of hydraulic oil is too high.

•When operating the electric pallet truck, the operator has to wear safety shoes.

•The truck is intended to be used for indoor applications with ambient temperatures

between +5C and + 40C.

•The operating lighting must be minimum 50 Lux.

•To prevent unintended sudden movements when not operating the truck (i.e. from

another person, etc.), press emergency switch (5) or remove the key (4).

4. COMMISSIONING, TRANSPORTING, DECOMMISSIONING

a.Commissioning

Table 2: Commissioning data

Type

PTE12N

(540X1150)

PTE12N

(685X1150)

Commissioning

weight [kg]

124kg

129kg

Dimensions [mm]

1530x540x1250

1530x685x1250

After receiving our new pallet truck or for re-commissioning you have to do following before (firstly)

operating the truck:

•Check if are all parts included and not damaged

•Make sure the tiller is assembled correctly (electrical socket is connected and fixed with two plastic

clamps, circlip of the axle is installed)

•Check that battery is charged (follow chapter 7)

•Do the work according to the daily inspections as well as functional checks.

b.Lifting/ transportation

For transporting, remove the load, lower the forks to the lowest position and fix the truck safe with

dedicated lifting gear according to the following figures.

Lifting

USE DEDICATED CRANE AND LIFTING EQUIPMENT

DO NOT STAND UNDER THE SWAYING LOAD

DO NOT WALK INTO THE HAZARDOUS AREA DURING LIFTING

11

Park the truck securely and lash the truck according to the points identified in Fig. 5. Lift the truck to its

destination and place the truck securely before removing the lifting gear. The lashing points are

according to the Fig. 5.

Transportation

DURING TRANSPORTATION ON A LORRY OR TRUCK ALWAYS FASTEN THE

TRUCK SECURELY

Lower the forks and park the truck securely.

Fasten the truck according to Fig. 6 by fixing dedicated lashing belts to each side of the trucks crane

hook holes and fasten the other side at the transporting truck.

c.Decommissioning

For storage, remove the load, lower the truck to the lowest position, grease all in this handbook

mentioned greasing points (regular inspection), and eventually protect the truck against corrosion and

dust. Remove the batteries and jack the truck safely, so that there will be no flattening after storage.

For final decommissioning hand the truck to a designated recycling company. Oil, batteries and electric

components must be recycled due to legal regulations.

5. DAILY INSPECTION

This chapter describes pre-shift checks before putting the truck into operation.

Daily inspection is effective to find the malfunction or fault on this truck. Check the truck on the following

points before operation.

Remove load from truck and lower the forks.

DO NOT USE THE TRUCK IF ANY MALFUNCTION IS FOUND.

•Check for scratches, deformation or cracks.

•Check if there is any oil leakage from the cylinder.

Fig. 5: Lifting with a crane

Fig. 6: fixing points

12

•Check the smooth movement of the wheels.

•Check the function of driving in both directions (section 6d).

•Check the functions of braking by activation of tiller arm sensor, reversing of driving

buttons, release of driving buttons and of the safety (belly) button (section 6f).

•Check the function of driving with tiller in its vertical position (section 6d).

•Check the function of the emergency brake by activating the emergency button.

•Check the lifting and lowering functions by operating the buttons (section 6b and 6c).

•Check the function of steering by turning the tiller from one end position to the other

one. The steering should be smooth, without jerks or abnormal sound.

•Check if all bolts and nuts are tightened firmly.

•Visual check if there are any broken electric wires.

•If supplied with a backrest extension, check it for damages and correct assembling.

•Check the presence of warning stickers and signs (section 2c and section 11)

6. OPERATING INSTRUCTIONS

BEFORE OPERATING THIS TRUCK, PLEASE FOLLOW THE WARNINGS AND

SAFETY INSTRUCTIONS (CHAPTER 3).

Make sure, that the load is palletized and stable and that the daily inspection is carried out.

Turn emergency button (Fig.1, 5) clockwise, and insert the key (Fig.1, 4).

Press the horn button (Fig.7, 15) to activate the audible warning signal.

a.Parking

DO NOT PARK THE TRUCK ON INCLINED SURFACES

The truck is equipped with an electromagnetic failsafe stopping and parking brake.

Always lower the forks fully. Press the emergency switch (5).

Fig.7: Tiller operating controls

13

Fig. 9: Operating direction

b.Lifting

DO NOT OVERLOAD THE TRUCK!

THE MAXIMUM CAPACITY OF PTE12N IS 1200 kg.

Travel with the lowered forks fully underneath the pallet and press the lifting button (Fig. 7, 16) until you

reached the desired lifting height.

c.Lowering

Press the lowering button (17) carefully.

Lower the load until the forks are clear of the pallet, then

drive the truck carefully out of the load unit.

d.Travelling

TRAVEL ON INCLINES ONLY WITH THE LOAD FACING UPHILL.

DO NOT TRAVEL ON INCLINES MORE THAN SPECIFIED WITH THE TECHNICAL

DATA.

After starting the truck by inserting the key, move the tiller to the operating zone (‘F’, Fig.9).

Turn the accelerator button to the desired direction forward ‘Fw.’ or backwards Bw.’(Fig. 9).

Control the travelling speed by moving the accelerator button (Fig.7,14) carefully until you reached the

desired speed. If you move the accelerator button back to the neutral position, the controller decelerates

the truck until the truck stops. If the truck stopped, the parking brake will be engaged.

Drive carefully the truck to the destination. Watch the route conditions and adjust the travelling speed

with the accelerator-button.

Press turtle button (Fig.7, 18) to enter into slow speed mode, travel slowly by moving the accelerator

Fig. 8: Load facing uphill

14

button (Fig.7,14) , press turtle button again to return back to regular mode.

Press turtle button and hold for 2 seconds to activate driving function with tiller in its vertical position

when operating in confined areas. The driving function is active only when turtle button is pressed (the

speed is reduced); the release of turtle button will cause immediate stop. The activation of accelerator

button in time gap shorter than two seconds after the turtle button is pressed will not activate the driving

function, the activation cycle has to be repeated from the beginning.Accelerator button should remain in

neutral position till two seconds passed.

e.Steering

You steer the truck by moving the tiller to the left or right side.

f. Braking

PLEASE CHECK THE BRAKING DISTANCE WITH TRUCK BEFORE OPERATION

THE BRAKING PERFORMANCE DEPENDS ON THE TRACK CONDITIONS AND

THE LOAD CONDITIONS OF THE TRUCK

The braking function can be activated on several ways:

•By moving the accelerator button (14) back to the initial ‘0’ position or by releasing the button, the

regenerative braking is activated. The truck brakes until it stops.

•By moving the accelerator button (14) from one driving direction directly to the opposite direction,

the truck brakes regenerative until it starts traveling into the opposite direction.

•The truck brakes, if the tiller is moved up or down to the braking zones (‘B’). If the tiller is released,

the tiller moves automatically up to the upper baking zone (‘B’).The truck brakes until it stops.

•The safety (belly) button (1) prevents the operator from being crushed. If this button is activated, the

truck decelerates and/ or starts traveling into the backwards direction (‘Bw.’) for a short distance and

stops. Please consider, that this button also operates, if the truck is not traveling and the tiller is in

the operating zone.

g.Malfunctions

If there are any malfunctions or the truck is inoperative, please stop using the truck and activate the

emergency button (5) by pushing it. If possible, park the truck on a safe area and remove the key (4).

Inform immediately the manager and, or call your service. If necessary, tow the truck out of the operating

area by using dedicated towing/ lifting equipment.

h.Emergency

In emergencies or in the event of tip over (or off dock), keep safe distance immediately. If possible push

the emergency button (5).All electrical functions will be stopped.

15

7. BATTERY CHARGING AND REPLACEMENT

•Only qualified personnel are allowed to service or charge the batteries. The

instructions of this handbook must be observed.

•The batteries are lithium batteries.

•Recycling of batteries undergoes national regulations. Please follow these

regulations.

•By handling batteries, open fire is prohibited!

•In the area of battery charging neither burning materials nor burning liquids are

allowed. Smoking is prohibited and the area must be ventilated.

•Park the truck securely before starting charging or installing/changing the batteries

•Before finishing the maintenance work, make sure, that all cables are connected

correctly and that there are no disturbing towards other components of the truck.

Table 3: Available batteries

Model

Battery

PTE12N

24V15Ah lithium battery, 4.4kg

IT IS ONLYALLOWED TO USE LITHIUM BATTERIES.

PLEASE CONSIDER THE MAXIMUM OPERATING TEMPERATURE OF THE

BATTERIES.

a.Replacement

Park the truck securely and press emergency switch (5). Hold the battery grip with one finger pull out the

lock, and then take out the battery vertically. The installation is in the reverse order.

Fig. 10: Battery replacement

Fig. 11: Battery discharge indicator

16

b.Battery indicator

Turtle Symbol:

It is normally off, when it appears (fixed) it shows activation of the “soft” mode of the truck, in which

maximum speed and acceleration are reduced.

Battery State of charge

Battery’s state-of-charge is indicated by four LED on the tiller:

The 1st green LED from left is on, indicating 75% -100% of battery power.

The 2nd blue LED from left is on, indicating 50% -75% of battery power.

The 3rd yellow LED from left is on, indicating 25% -50% of battery power.

The 4th LED from left is on, indicating 0% -25% of battery power.

If there is fault code, four LEDs will flash for 1s, then the 1st green LED from left will flash and count,

after that the 4th LED from left will flash and count. The amount that green LED flashes times ten, then

plus the amount that led LED flashes means the fault code.

c.Charging

•Before charging ensure that you are using an appropriate charger for charging the

installed battery.

•Before using the charger, please fully understand the instructions of the charger

instructions.

•Always follow these instructions.

•The room, where you are charging must be ventilated.

•The exactly charge status can be only checked from the discharge indicator. To

control the status, the charging must be interrupted and the truck must be started.

17

Park the truck at a dedicated secured area with a

dedicated power supply.

Lower the forks and remove the load;

Switch the truck off and connect the charger plug (20) to

the charging port (21) on the battery. The charger starts

charging the battery if the charger plug (19) is connected

to the main power supply.

Disconnect the charger plug from the battery and close

the cap after the charger finished charging.

When charging is finished, disconnect the plug (19) from

the socket and place it in the designated pocket.

It’s also allowed to remove the battery out and charge in

dedicated area.

Table 4: LED-Status

LED- signal

Function

Red

Charging

Green

Fully charged

Table 5: Charger PTE12N

8. REGULAR MAINTENANCE

•Only qualified and trained personnel are allowed to do maintenance on this truck.

•Before maintaining, remove the load from the forks and lower the forks to the

lowest position.

•If you need to lift the truck, follow chapter 4b by using designated lashing or jacking

equipment. Before working, put safety devices (for instance designated lift jacks,

wedges or wooden blocks) under the truck to protect against accidental lowering,

movement or slipping.

•Please pay attention by maintain the tiller arm. The gas pressure spring is

pre-loaded by compression, carelessness can cause injury.

•Use approved and from your dealer released original spare parts.

•Please consider that oil leakage of hydraulic fluid can cause failures and accidents.

•It is allowed to adjust the pressure valve only from trained service technicians.

Check the items emphasized in maintenance checklist.

Model

Specification

Input

Output

DZL2420SS02

24V5A (Chinese sticker)

180Vac -240Vac~2.0A MAX

29.4V 5.0A

DZL2420SS02

24V5A (English sticker)

180Vac -240Vac~2.0A MAX

29.4V 5.0A

S12030-C0500

24V5A (US)

100Vac -240Vac~3.5A MAX

29.4V 5.0A

SSLC165V29

24V5A (EU)

180Vac -240Vac~3.0A MAX

29.4V 5.0A

Fig.12: Battery charging

18

a.Maintenance checklist

Table 6: Maintenance checklist

Interval(Month)

1

3

6

12

Hydraulic

1

Check the hydraulic cylinder(s), piston for damage noise and leakage

•

2

Check the hydraulic joints for damage and leakage

•

3

Inspect the hydraulic oil level, refill if necessary

•

4

Refill the hydraulic oil ( 12 month or 1500 working hours )

•

5

Check and adjust function of the pressure valve (1200kg(PTE12N)+0/+10%)

•

Mechanical system

6

Inspect the forks for deformation and cracks

•

7

Check the chassis for deformation and cracks

•

8

Check if all screws are fixed

•

9

Check the push rods for deformation and damages

•

10

Check the gearbox for abnormal sound and noise

•

11

Inspect the wheels for deformation and damages

•

12

Inspect and lubricate the steering bearing if necessary

•

13

Inspect and lubricate the pivot points if necessary

•

14

Lubricate the grease nipples

•

Electrical system

15

Inspect the electric wiring for damage

•

16

Check the electric connections and terminals

•

17

Test the Emergency switch function

•

18

Check the electric drive motor for noise and damages

•

19

Test the display

•

20

Check, if correct fuses are used

•

21

Test the warning signal

•

22

Check the contactor(s)

•

23

Check the frame leakage (insulation test)

•

24

Check function and mechanical wear of the accelerator

•

25

Check the electrical system of the drive motor

•

Braking system

26

Check brake performance, if necessary replace the brake disc or adjust the air gap

•

Battery

27

Check the battery voltage

•

28

Clean and grease the terminals and check for corrosion and damage

•

29

Check the battery housing for damages

•

Charger

30

Check the main power cable for damages

•

31

Check the start-up protection during charging

•

Function

32

Check the horn function

•

33

Check the air gap of the electromagnetic brake

•

Table of contents

Other Noblelift Truck manuals

Noblelift

Noblelift PS E12BSL manual

Noblelift

Noblelift PTE15Q-A User manual

Noblelift

Noblelift FE3P16-35 N User manual

Noblelift

Noblelift RT16Li User manual

Noblelift

Noblelift PTE15Q2-B User manual

Noblelift

Noblelift PT20H manual

Noblelift

Noblelift PTE15Q User manual

Noblelift

Noblelift N Series Manual

Noblelift

Noblelift PTE15Q User manual

Noblelift

Noblelift RT16P User manual