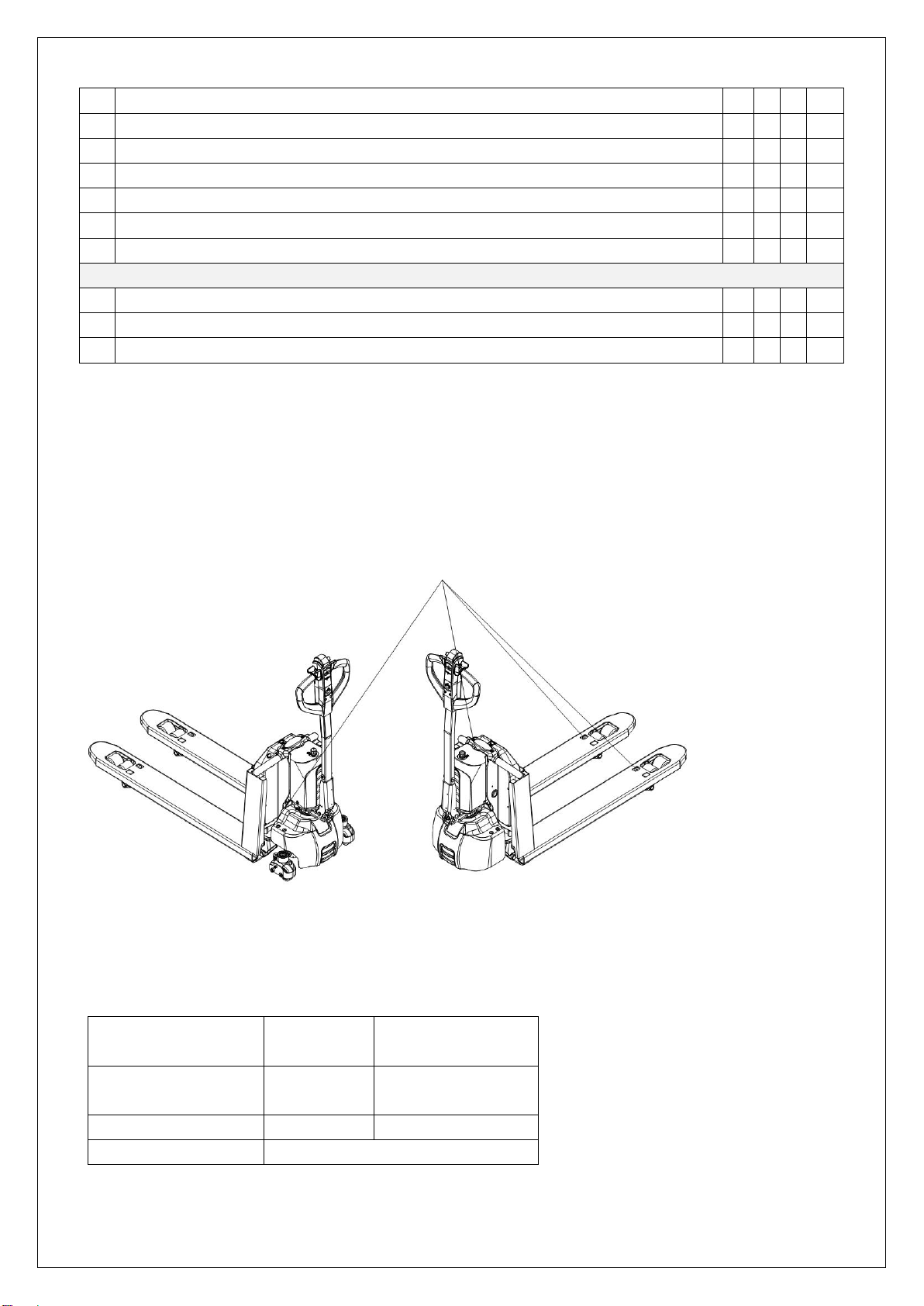

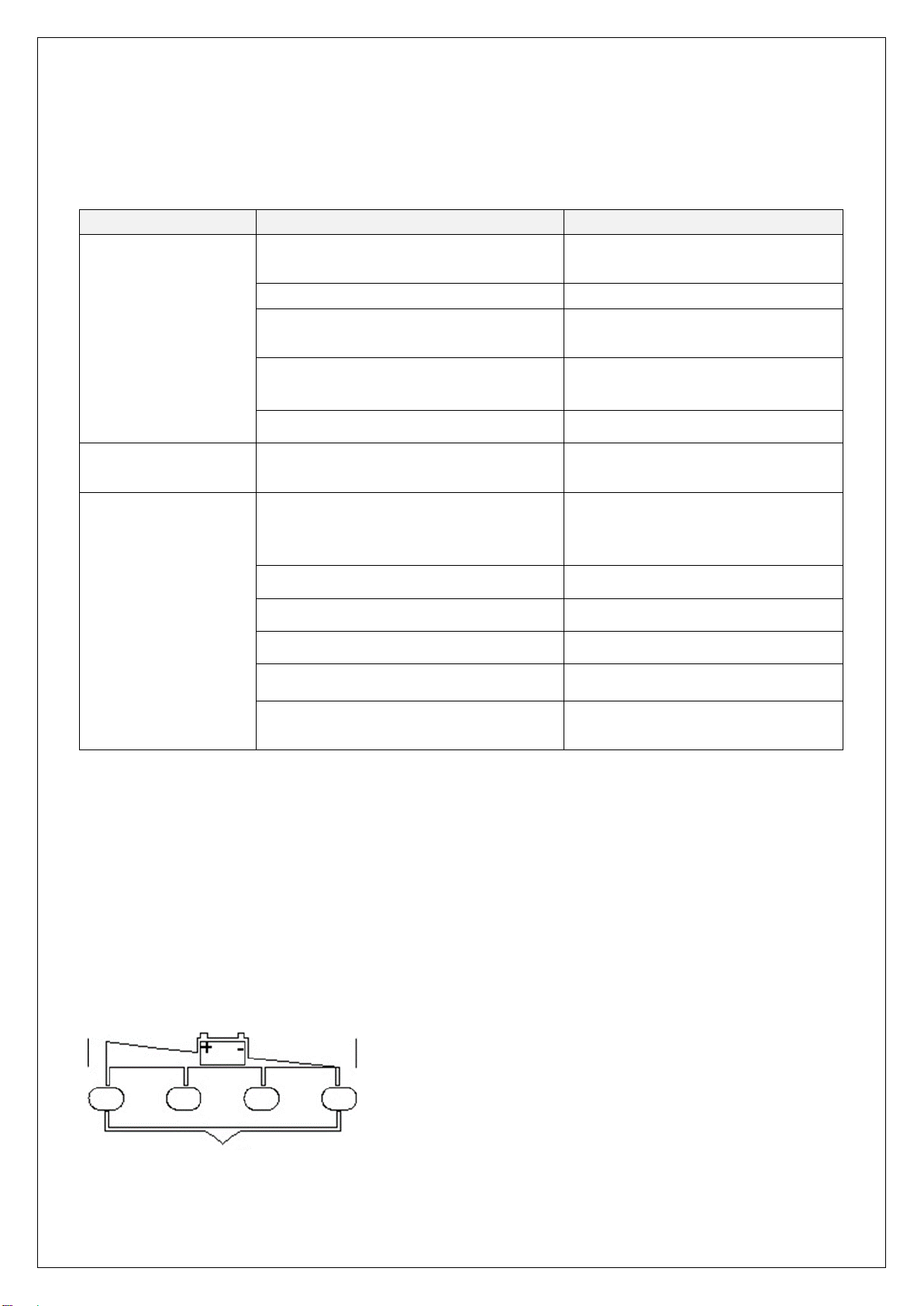

Fault code

displayed on

handle

Fault description Solution Fault source

(UpRight_Fault) the interlock switch is closed when upright driving

The interlock switch is closed in the upright driving mode. If the upright

driving switch (tortoise speed switch) is released, the fault has not been

cleared after resetting the interlock:

1. The uprightl drive switch (tortoise speed switch) is stuck, and the handle

shall be replaced“

1. The interlock switch is closed in advance before

startup

2. Wrong operation sequenceof direction and

interlock

3. Interlock switch is disconnected first and then

closed during operation

If the interlock is reset, the fault has not been cleared:

1. Check whether the interlock switch harness (J1-9) is short circuited with

3 -;

2. Replace the interlock switch;

1. Accelerator damaged

2. Handle analog quantity > 4096 or < 0

Accelerator analog out of range

1. Replace the handle BM24C10-CAN controller

Precharge_Fault The precharge circuit is damaged

Check whether the KSI port (J1-6) is in good contact

If there is no abnormality, replace the controller

Precharge_Fault Precharge time is too long

Check whether the KSI port (J1-6) is in good contact

If there is no abnormality, replace the controller

1. The main contactor is stick together or get stuck

2. Main contactor drive failure

replace the controller BM24C10-CAN controller

MainOn_Fault 1. The main contactor drive loop is open replace the controller BM24C10-CAN controller

1. Short circuit in brake drive loop

2. Short circuit of brake coil

replace the controller BM24C10-CAN controller

BatDisconnect_Fault Poor connection of battery B +, B- circuit

Check whether the power line B + / B - is well connected;

If there is no problem, replace the controller

1. Open circuit of brake drive circuit

2. Open circuit of brake coil

1. Check whether the electromagnetic brake harness (J1-1 /J1-2) is well

connected;

2. If the electromagnetic brake is damaged, replace the electromagnetic

brake;

3. Replace the controller;

Hardware_Fault Controller hardware failure, replace the controller replace the controller BM24C10-CAN controller

OutRange_15V Internal 15V voltage > 18 volts or < 12 volts replace the controller BM24C10-CAN controller

1. M1 bridge arm fault and MOSFET damage

2. The motor line is short circuited to the outside

1. Replace the controller

2. Check whether M1 motor line is short circuited with B + / B - / motor

housing, and replace the motor;

1. M1 bridge arm fault and MOSFET damage

2. The motor line is short circuited to the outside

1. Replace the controller

2. Check whether M2 motor line is short circuited with B + / B - / motor

housing, and replace the motor;

1. The motor is not connected

2. Motor M1 and M2 circuits are poorly connected“

1. Check whether the connection between the motor line and the controller

is good;

The controller current is greater than the protection

value

1. Short circuit of motor or motor line;

2. Restart. If the fault still exists, replace the controller

Controller_Temp_Fault Controller temperature > 100 ℃ or < - 40 ℃

1. Whether the actual temperature of the controller is too high or too low;

2. If the controller temperature is - 40 ℃<T < 100 ℃, replace the

controller

OverVoltage_Fault Battery voltage < 17 Volts

Battery voltage too high

1. Check whether the battery voltage is higher than 35V

UnderVoltage_Fault Battery voltage <17 Volts

Battery voltage too low

1. Check whether the B + / B - power line is well connected;

2. If the battery voltage is too low ,charge it;

3. If the battery is damaged, replace the battery;

4. If the voltage is normal and the fault still exists, replace the controller;

EEprom_Fault EEPROM read / write parameter failure replace the controller BM24C10-CAN controller

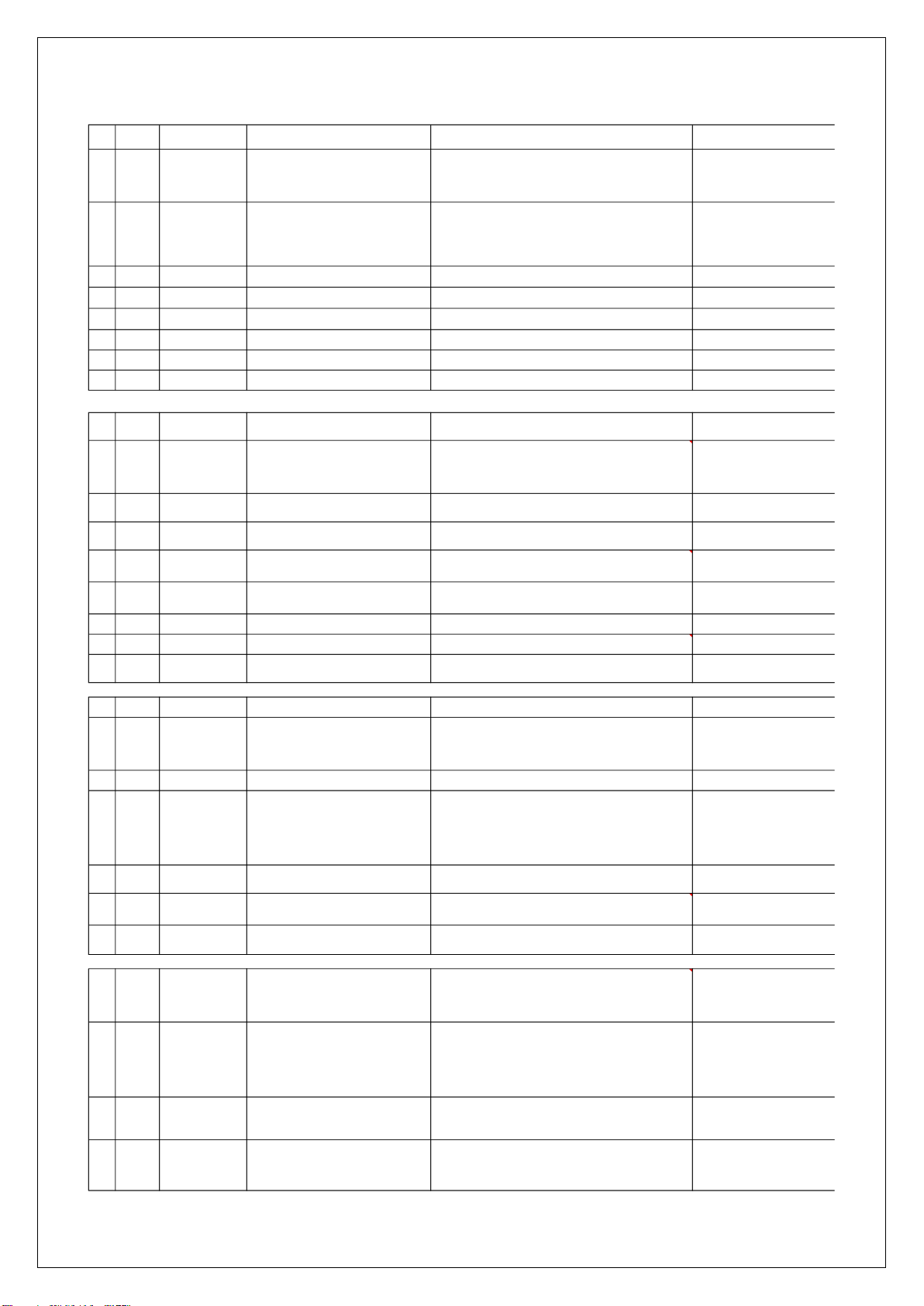

1. Check CAN line connection and CAN-BUS

resistance;

2. Check the lithium battery BMS;

1. Check whether the can lines of battery, handle and controller are

connected correctly;

2. Measure whether there is 60 Ω terminal resistance on CAN-BUS;

3. If the lithium battery BMS is damaged, replace the lithium battery;

4. If the handle communication module is damaged, replace the handle;

5. If the controller communication module is damaged, replace the

controller

1. The relay drive circuit is short circuited.

2. Relay coil short circuit

replace the controller BM24C10-CAN controller

1. Open circuit of relay drive circuit.

2. Open circuit of relay coil

1. Check whether the lifting relay harness (J1-5 / 3 -) is well connected

2. If the lifting contactor is damaged, replace the lifting contactor;

3. Replace the controller;

1. The relay drive circuit is short circuited.

2. Relay coil short circuit

replace the controller BM24C10-CAN controller

1. Open circuit of relay drive circuit.

2. Open circuit of relay coil

1. Check whether the descending solenoid valve harness (J1-7 / 3 -) is well

connected

2. If the lowering solenoid valve is damaged, replace the lowering solenoid

valve;

3. Replace the controller;

1. Before the key switch is powered on, the

emergency reverse switch is closed

2. Emergency reverse logic failure

The emergency reverse is triggered normally and an emergency reverse

fault is reported. If the fault is not cleared after resetting the interlock:

1. Check whether the emergency reverse switch harness (J1-13) is

connected well;

2. The emergency reverse switch is stuck;

3. Whether the type parameter setting of emergency reverse switch is

correct;

BMSTimeout_Fault Failed to connect with BMS 7S after power on

1. Check whether the CAN line between the battery and the controller is

well connected;

2. Check whether the controller software is correct;

3. Check whether the battery BMS software is correct;

The tortoise speed button detects closure before

power on.

1. Whether the handle speed button is pressed and stuck;

2. Check whether the microswitch under the turtle speed button is

normally closed, and replace the microswitch assembly;

3. Replace the upper cover of the handle;