4

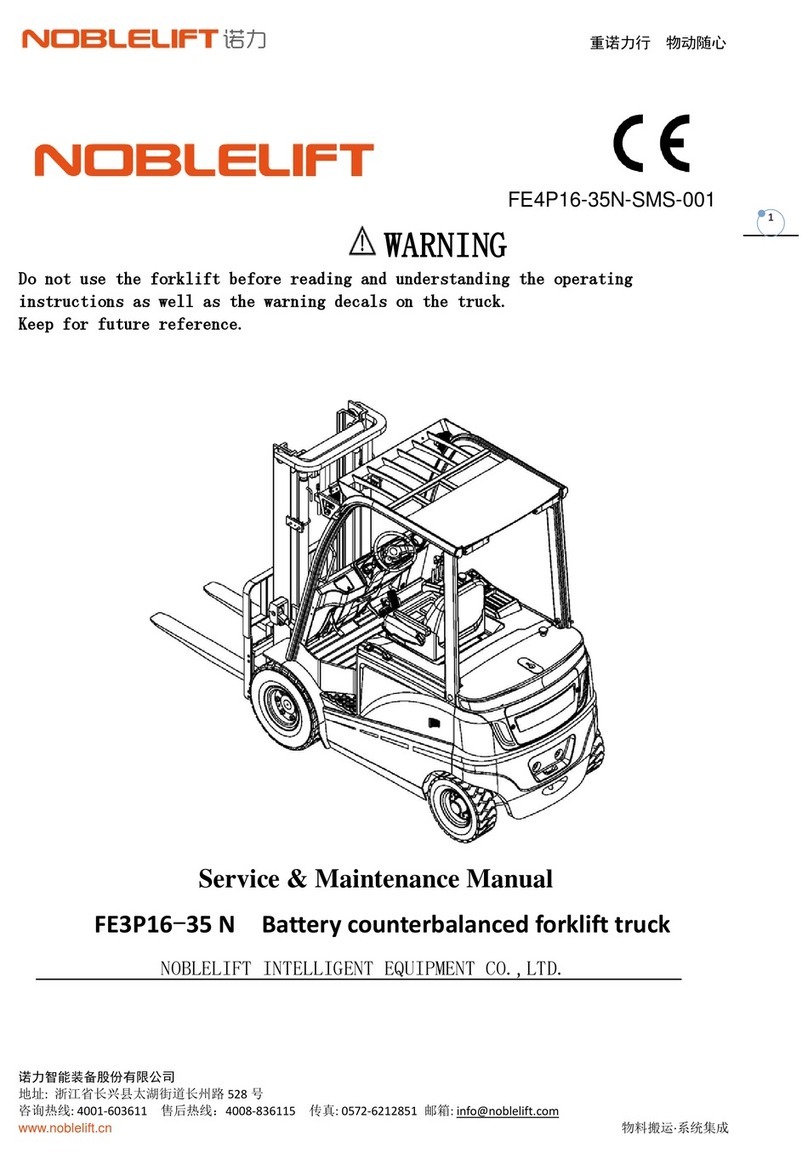

1. CORRECT APPLICATION

To ensure the safety of personal and equipment, drivers shall observe the following precautions:

1. Only drivers who have been trained and hold a industrial trucks driving license can drive this truck;

2. This reach truck is suitable for hard and flat indoors floor conditions;

3. Check the control and alarm devices before driving this reach truck. If any damage or defect is

found, it shall be operated after repair;

4. During handling, the load shall not exceed the specified value. Both forks should go under the

goods and load should be evenly placed on the forks. Unbalanced loading is prohibited and picking

up objects with single fork is not allowed;

5. Start, steer, drive, brake and stop slowly and smoothly. Slow down when steering on wet or smooth

floors;

6. When driving this reach truck with goods, lower the goods as low as possible and the forks should

be tilted backward;

7. Be careful when driving on the slope: move forward uphill, move backward downhill, avoid steering

uphill or downhill;

8. When driving this reach truck, pay attention to pedestrians, obstacles and potholes, and pay

attention to the clearance above the reach truck;

9. It is not allowed to stand on forks or truck;

10. It is not allowed to stand under or walk under the elevated part of the truck;

11. Only operate the truck from the driver's position;

12. Do not handle unsecured or loosely packed goods, and carefully handle goods in large size;

13. When driving in the racks, drive slowly, move straightly in and straightly out, when the fork is not

completely removed from the racks, do not steer in case of collision.

14. For high lifted trucks, try to make the mast tilted back, and the tilting forward and backward during

loading and unloading should be done within the minimum range;

15. Immediately stop using when the failure occurs, and the label shall be clearly indicated;

16. Lower the forks to the ground when leaving the truck, park the truck on level ground, turn off the

power and remove the key.

It is only allowed to use this electric reach truck according to this instruction manual.

The capacity is marked on capacity sticker as well on the identification plate. The operator has to pay

attention to the warnings and safety instructions.

Operating lighting must be minimum 50 Lux.

Modification

No modifications or alterations to this reach truck which may affect, for example, capacity, stability or

safety requirements of the truck, shall be made without the prior written approval of the original truck

manufacturer, its authorized representative, or a successor thereof. This includes changes affecting, for

example braking, steering, visibility and the addition of removable attachments. When the manufacturer

or its successor approve a modification or alteration, they shall also make and approve appropriate

changes to capacity plate, decals, tags and operation and maintenance manual.

Only in the event that the truck manufacturer is no longer in business and there is no successor in the interest to the business, may the

user arrange for a modification or alteration to a powered industrial truck, provided, however, that the user:

a) arranges for the modification or alteration to be designed, tested and implemented by an engineer(s) expert in industrial trucks and

their safety,

b) maintains a permanent record of the design, test(s) and implementation of the modification or alteration,

c) approves and makes appropriate changes to the capacity plate(s), decals, tags and instruction handbook, and

d) affixes a permanent and readily visible label to the truck stating the manner in which the truck has been modified or altered, together

with the date of the modification or alteration and the name and address of the organization that accomplished those tasks.

By not observing these instructions, the warranty becomes void.